Novel flat-plate heat pipe with stratose microflute subfebrile temperature tube group

A flat heat pipe and micro heat pipe technology, applied in the direction of tubular elements, indirect heat exchangers, heat exchange equipment, etc., can solve the problem of small thermal resistance, heat exchange efficiency, structure, pressure bearing capacity, processing technology and heat exchange performance are under development stage and other issues, to achieve the effect of improving thermal conductivity, saving material consumption, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

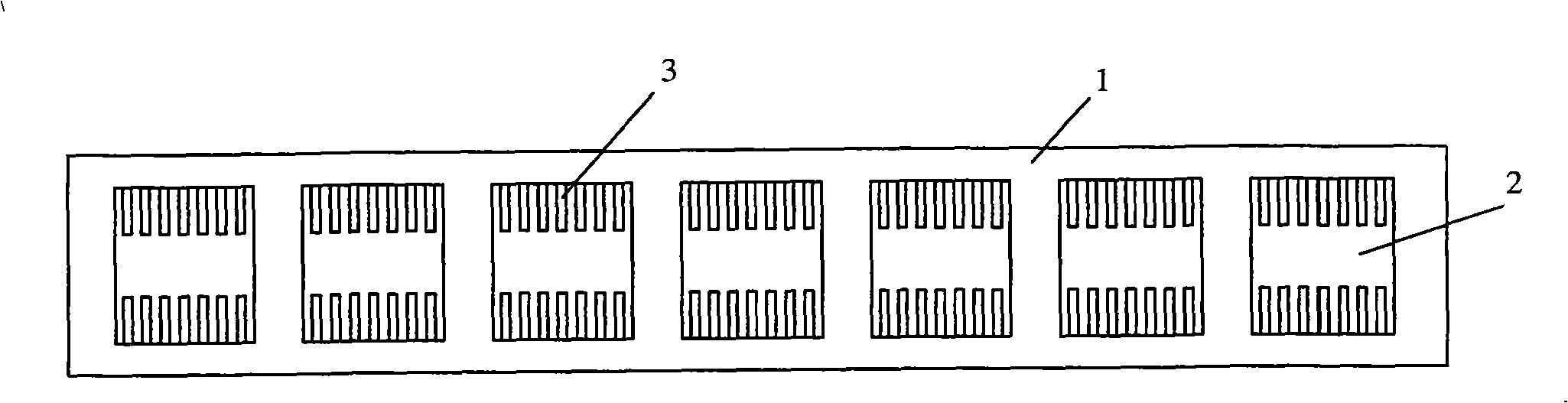

[0022] figure 1 One embodiment of the invention is shown.

[0023] The flat heat pipe includes an extruded flat frame 1. The flat frame 1 includes a group of rectangular through holes 2 arranged side by side. A group of micro fins 3 are arranged on the two opposite inner walls of the through holes 2. The micro fins 3 are integrated with the flat frame 1. extruded.

[0024] The flat heat pipe of the present invention is made of metal with good thermal conductivity, especially aluminum.

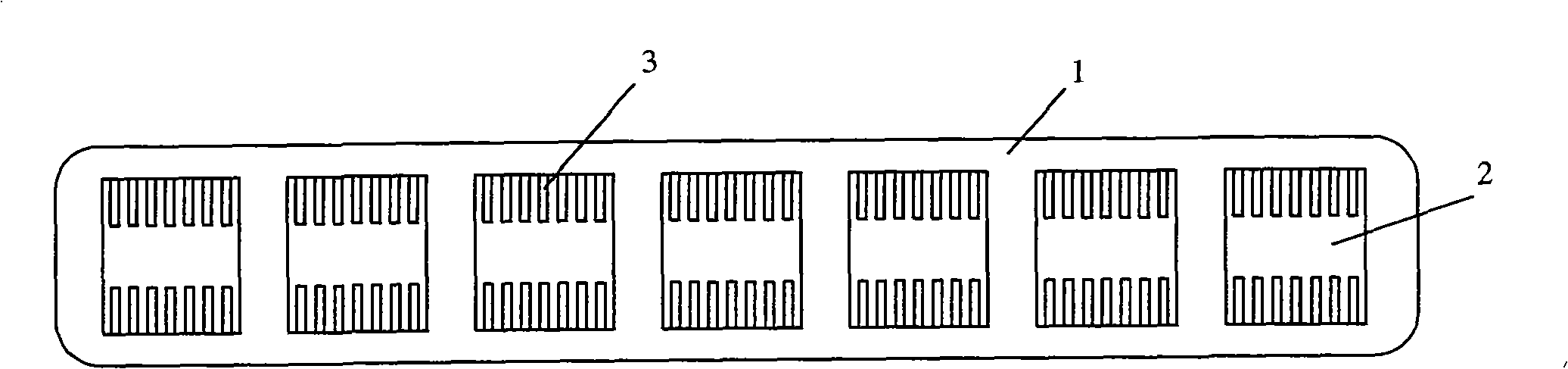

[0025] figure 2 Shown is a schematic structural view of another embodiment of the present invention.

[0026] In this example and figure 1 The difference shown is that the edges and corners of the flat frame 1 are all arcs, which is not only convenient for extrusion preparation, but also convenient for transportation.

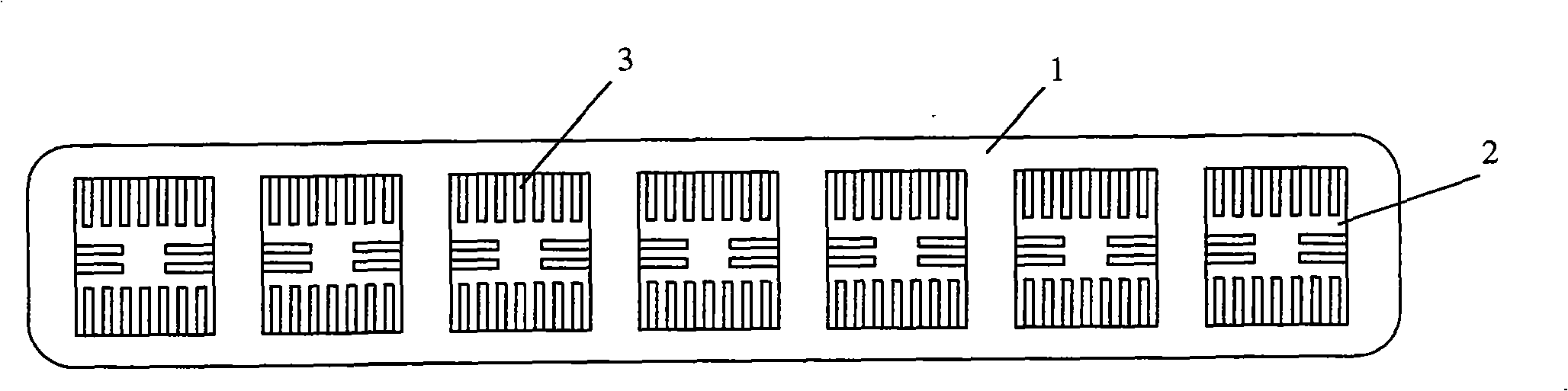

[0027] image 3 Shown is a schematic structural view of ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com