Cylindrical capillary pump assembly of loop heat pipe

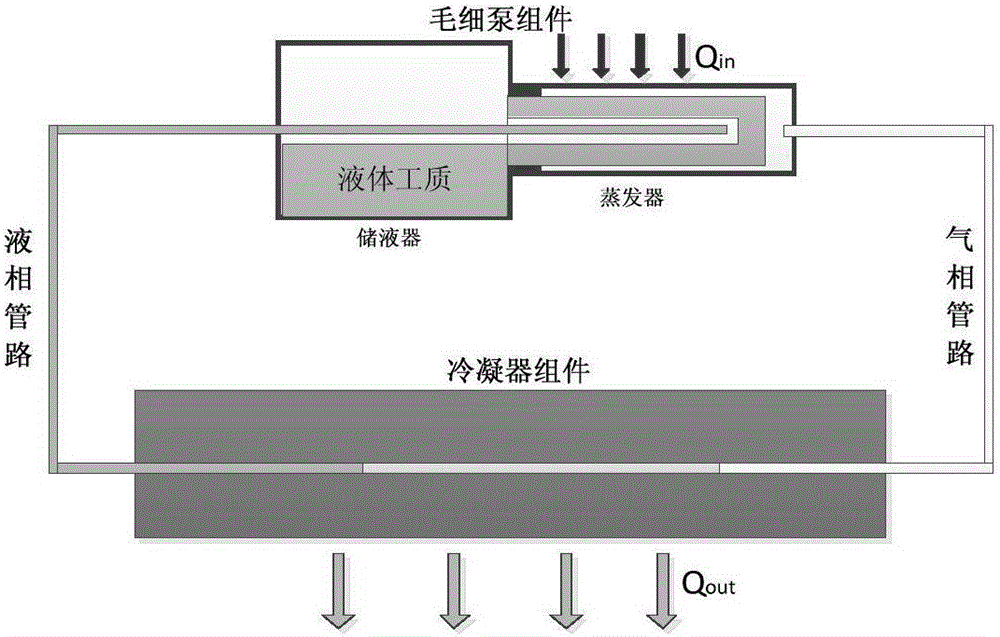

A loop heat pipe and capillary pump technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of reducing the service life of the loop heat pipe, increasing the decomposition rate of the working fluid, and reducing the open porosity. The effect of reducing reverse heat leakage, improving mechanical properties, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

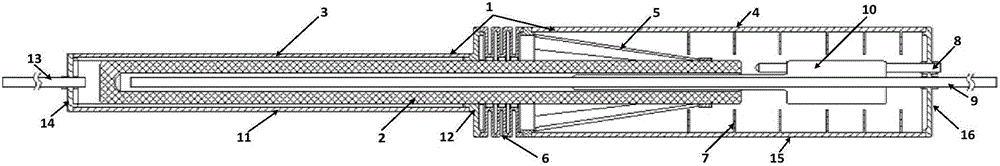

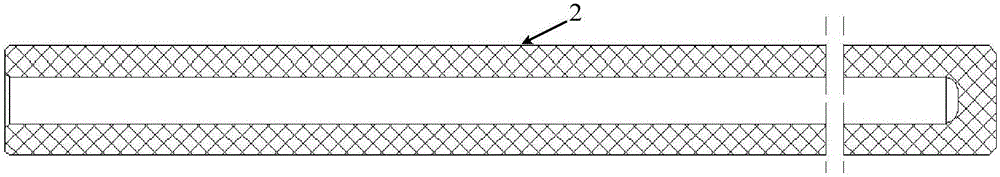

[0032] Such as figure 2 As shown, it is a schematic structural diagram of a cylindrical loop heat pipe capillary pump assembly of the present invention, which mainly includes a tube shell 1 and a capillary wick 2 . The tube shell 1 is composed of two parts, the evaporator shell 3 and the liquid reservoir shell 4 . One section of the capillary 2 is located inside the evaporator housing 3, and the other section extends into the interior of the liquid reservoir housing 4, so that two independent cavities of the vapor chamber and the liquid storage chamber are formed inside the capillary pump assembly.

[0033] The evaporator shell 3 includes a first main shell 11 and a second main shell 12. The inner wall of the main shell 11 is provided with axial micro channels, and the inner wall of the second main shell 12 is designed to be smooth. The outer wall of the capillary core 2 located at the inner section of the evaporator housing 3 closely cooperates with the inner wall of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective aperture | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com