Temperature control gas phase working medium perfusion method for micron heat pipe

A technology of micro heat pipes and working fluid, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large environmental impact, unusable perfusion volume, loss of working medium, etc., and achieve less loss of working medium and repeated perfusion Good performance and efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

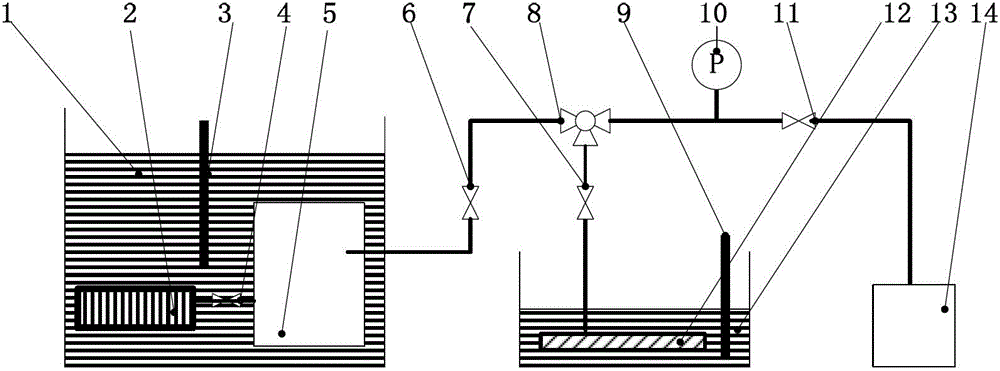

[0018] The schematic diagram of the device structure of the present invention is shown in Figure 1, and consists of three parts: a working medium supply part, a micro heat pipe part and a vacuum pipeline system. The working medium supply part is composed of a first constant temperature water bath 1, a working medium 2, a first temperature sensor 3, a solenoid valve 4 and a working medium sealing chamber 5. The micro heat pipe part is made up of the second temperature sensor 9, the micro heat pipe 12 and the second constant temperature water bath 13. The vacuum pipeline system is composed of a first vacuum valve 6 , a second vacuum valve 7 , a three-way reversing valve 8 , a vacuum gauge 10 , a third vacuum valve 11 and a vacuum pump 14 .

[0019] In this embodiment, the temperature control system adopts a water bath temperature control device, and other temperature control devices such as a hot plate and a constant temperature oven may also be used. The working medium for per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com