Loop heat pipe

A loop heat pipe and pipeline technology, used in circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as drying up, affecting heat transfer efficiency, burning loss, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

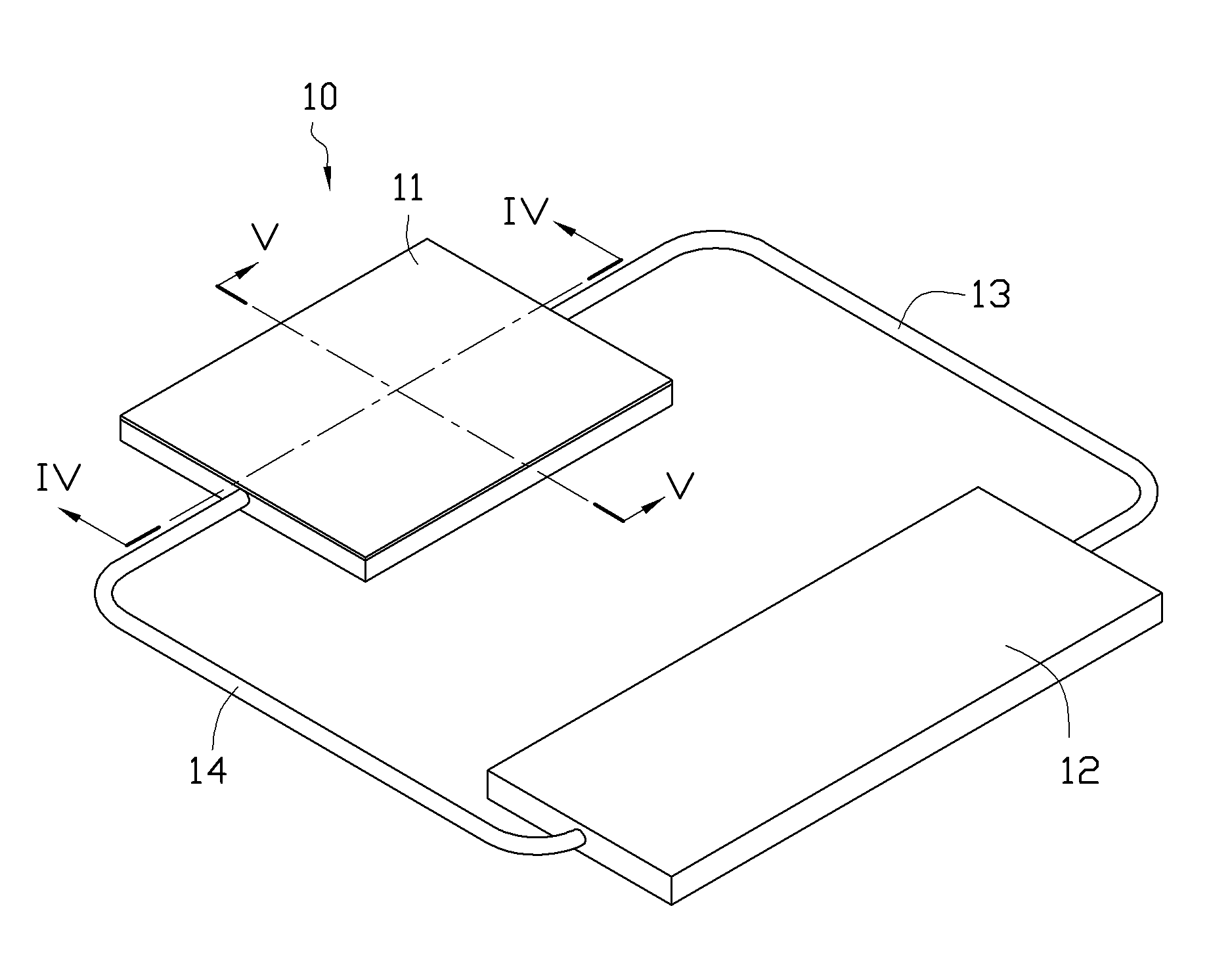

[0018] Please refer to figure 1 , The loop heat pipe 10 in the first embodiment of the present invention includes an evaporator 11 , a condenser 12 , a vapor line 13 and a liquid line 14 .

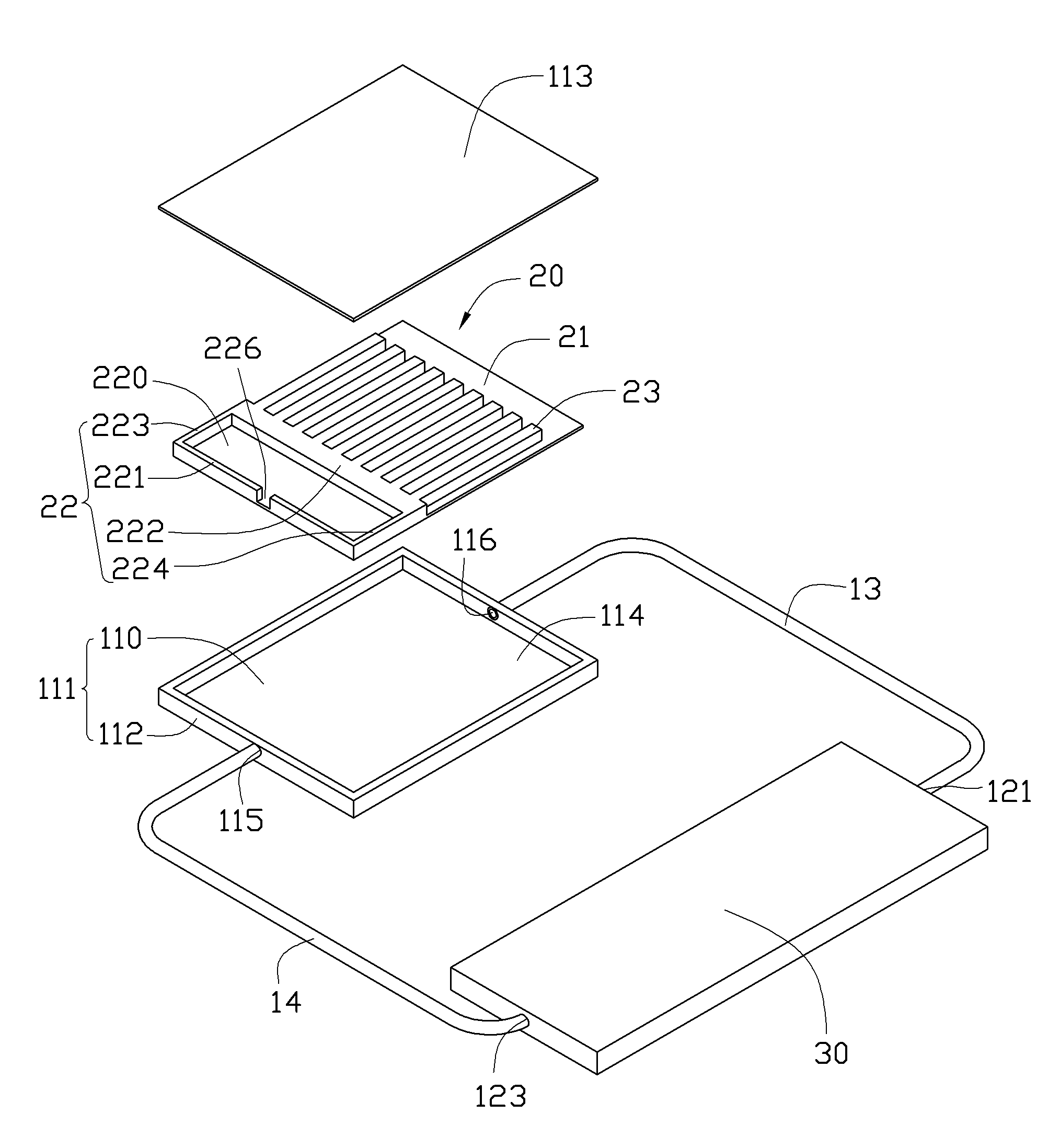

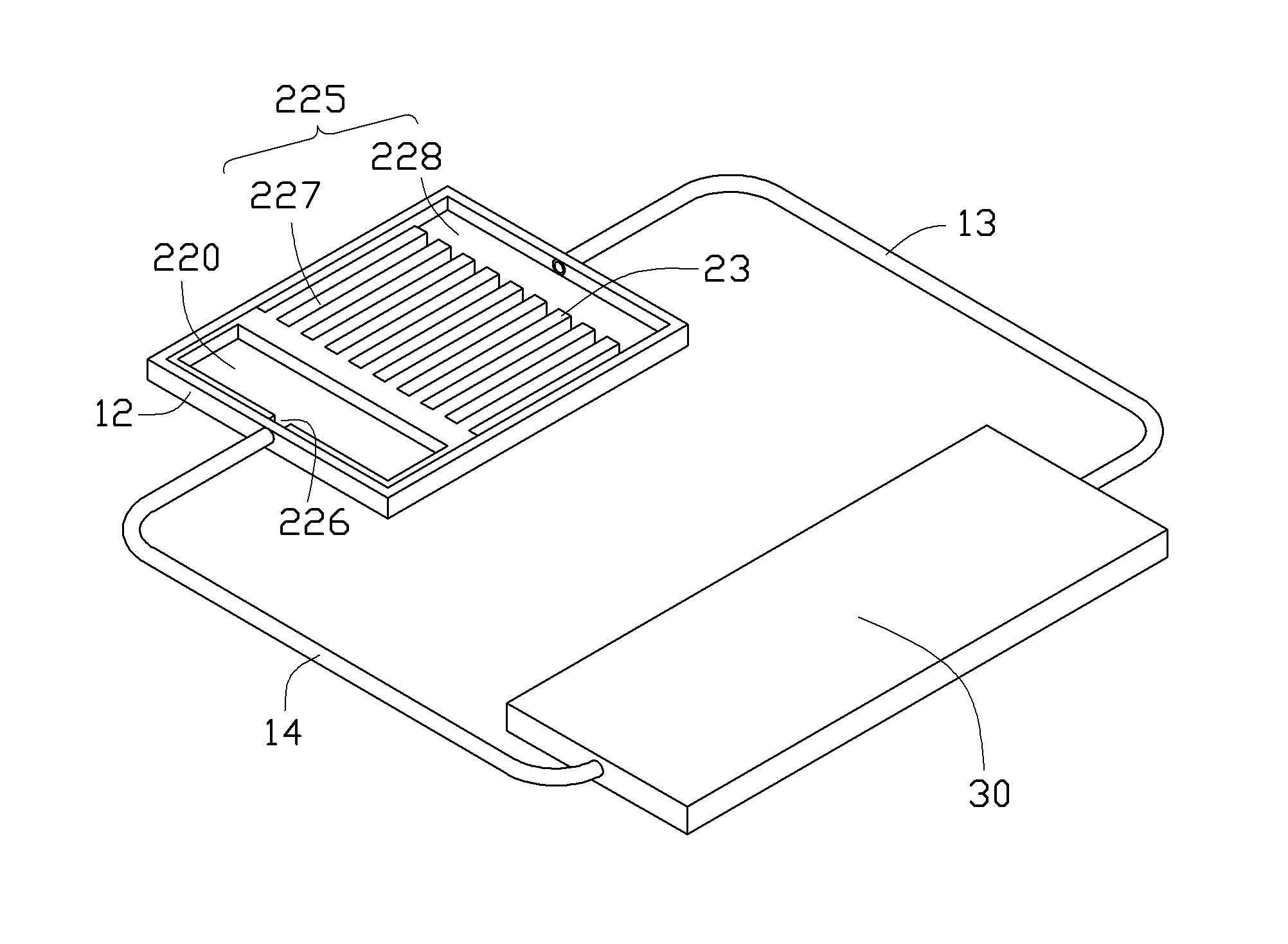

[0019] Please also refer to figure 2 , the evaporator 11 is rectangular and includes a base 111 , a capillary structure 20 accommodated in the base 111 and a cover plate 113 covering the base 111 . The base 111 includes a rectangular bottom plate 110 and a side plate 112 extending upward from a periphery of the bottom plate 110 . The cover plate 113 covers the top of the side plate 112 , and the bottom plate 110 , the side plate 112 and the cover plate 113 together form a receiving space 114 for accommodating the capillary structure 20 . An evaporator inlet 115 connected to one end of the liquid line 14 and an evaporator outlet 116 connected to one end of the vapor line 13 are respectively provided on the side plates 112 at the left and right ends of the evaporator 11 .

[0020] The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com