Loop heat pipe with wick passageways and heat transmission method and manufacturing method thereof

A technology of loop heat pipe and manufacturing method, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., and can solve the problem that loop heat pipes cannot be widely used, air-cooled heat dissipation cannot meet heat dissipation requirements, and limit the application field of loop heat pipes and other problems, to achieve the effect of superior heat transfer performance, superior performance, and reduced thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

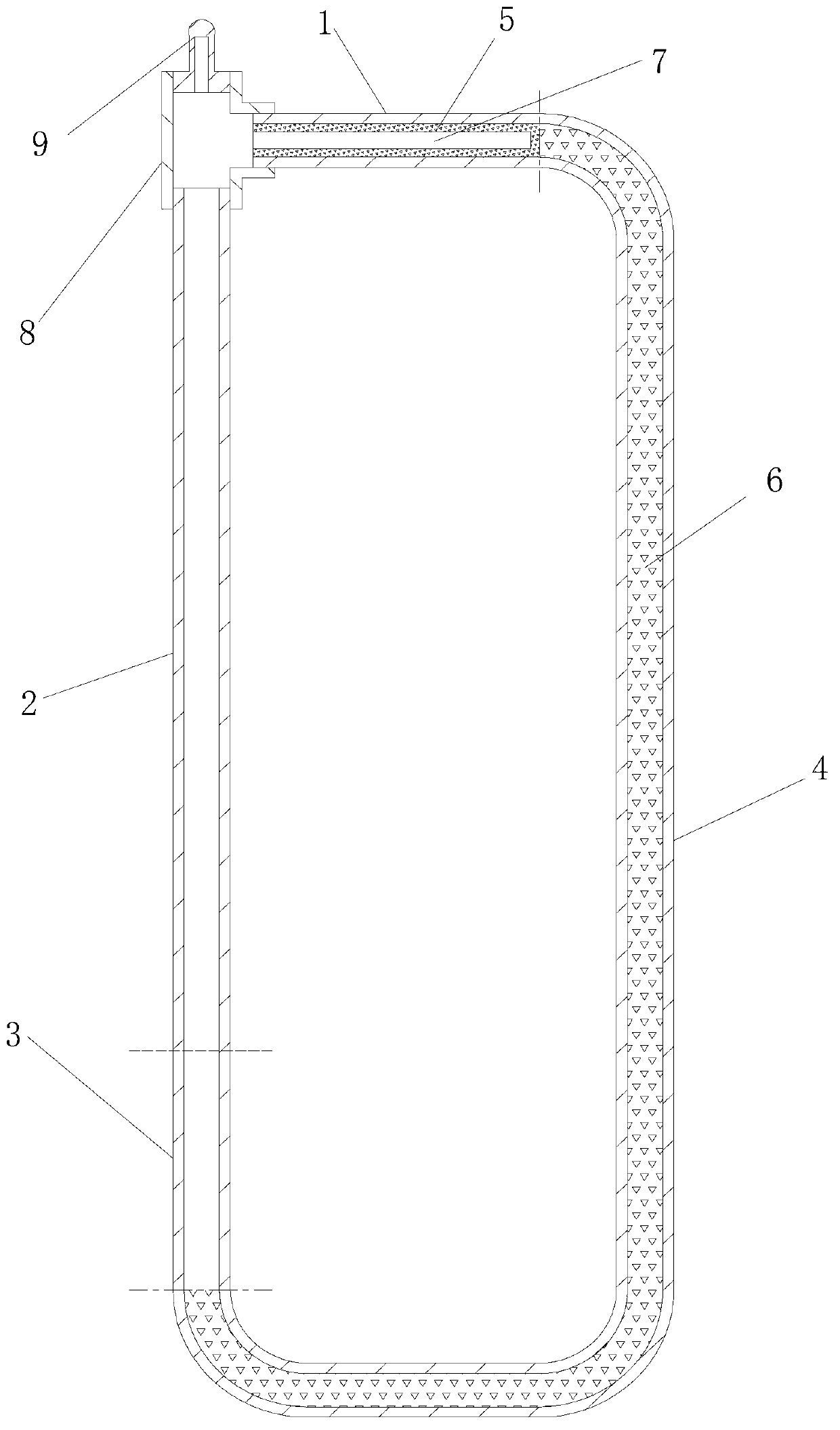

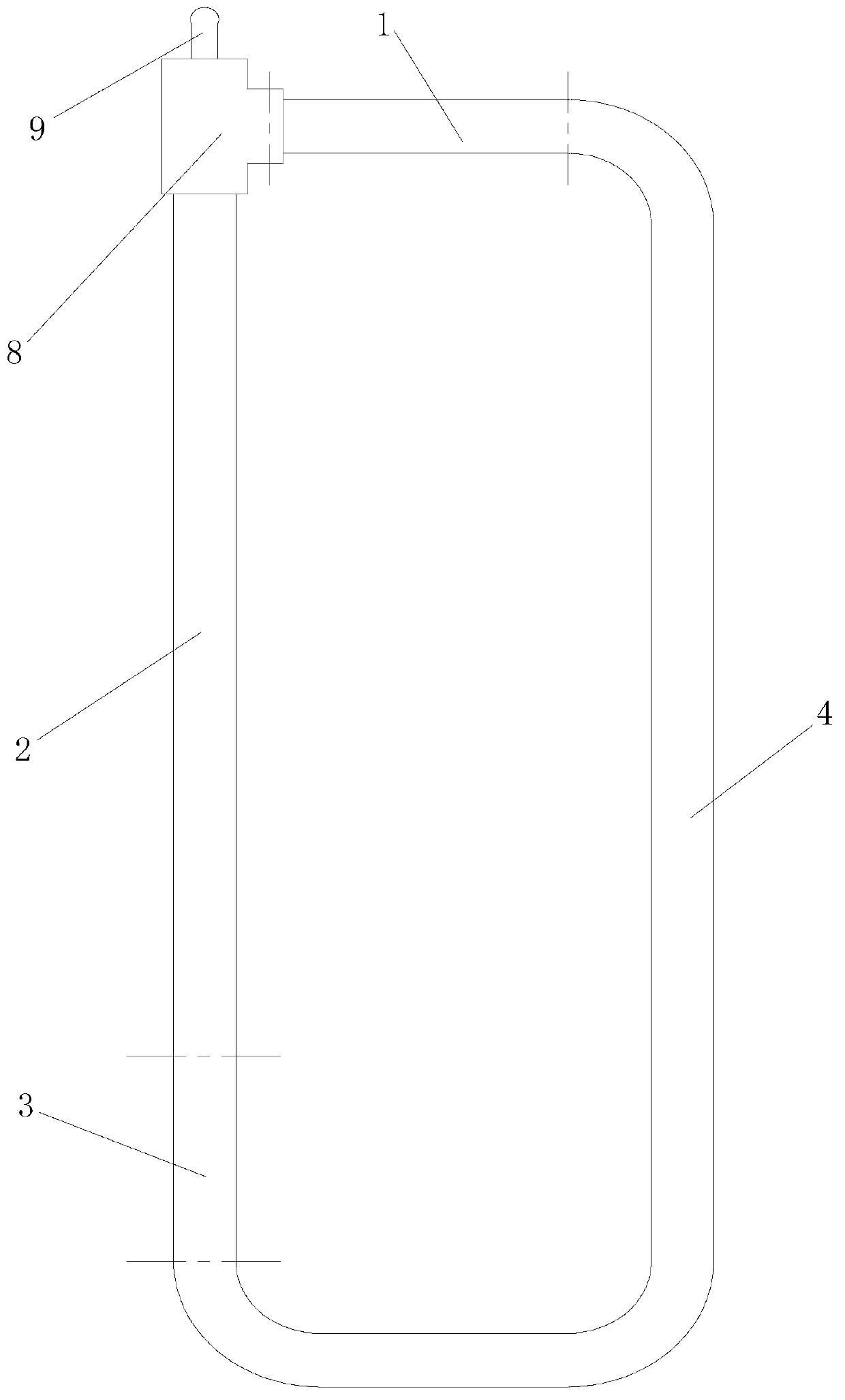

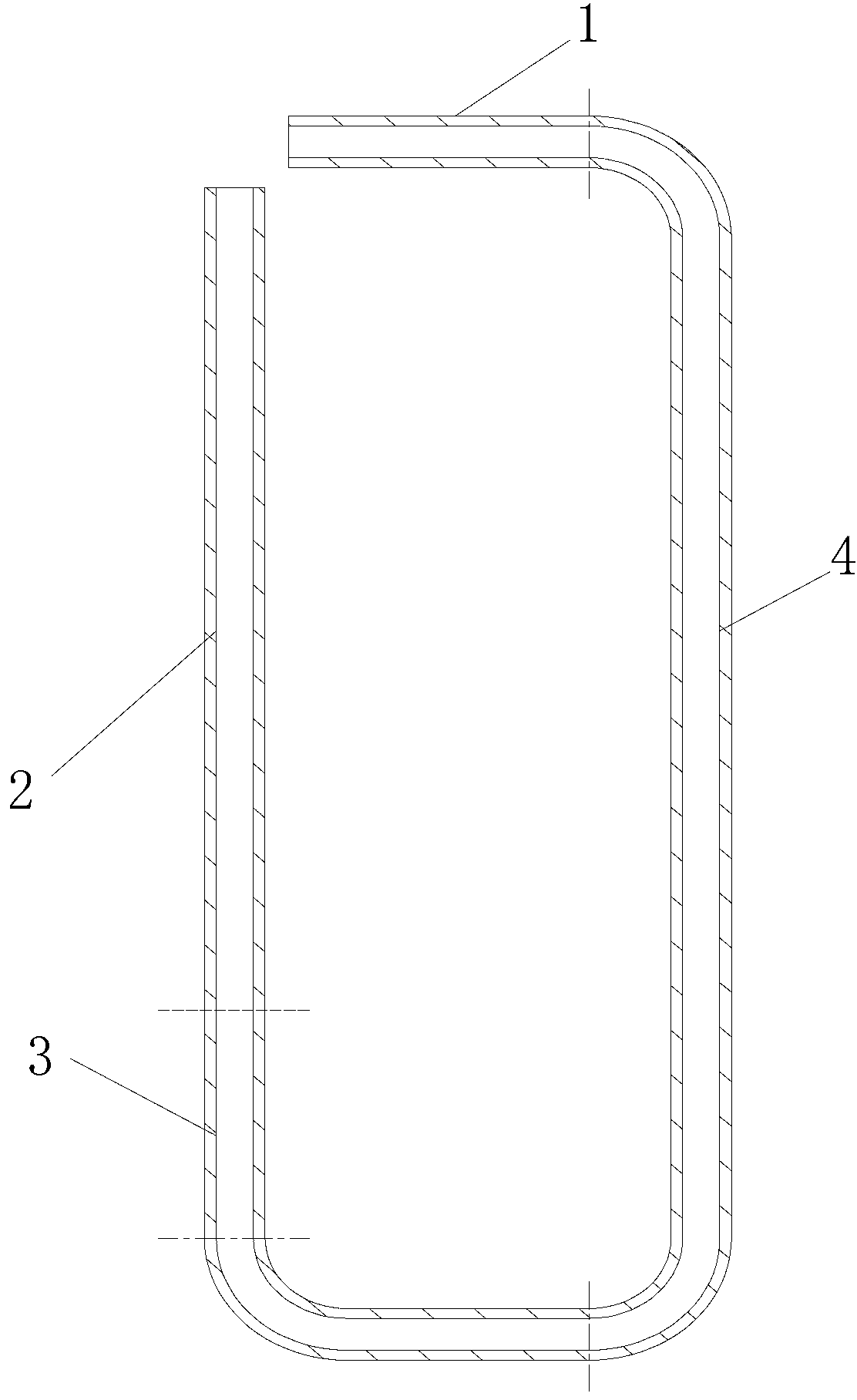

[0030] Such as figure 1 and figure 2 A loop heat pipe shown with a liquid-absorbing wick flow path includes an evaporation section 1, an adiabatic section 2, a condensation section 3, and a liquid infusion section 4 that are sequentially connected end to end to form a loop. The evaporation section 1 and the liquid infusion section 4 The tube body is filled with sintered metal powder, the tube body of the evaporation section 1 and the metal powder form the first liquid-absorbing wick flow channel 5, and the tube body and the metal powder of the infusion section 4 form the second liquid-absorbing wick flow Road 6.

[0031] A round hole 7 concentric with the tube body of the evaporating section 1 is provided in the first liquid-absorbing wick flow channel 6 , and the round hole 7 communicates with the heat insulating section 2 .

[0032] The thickness of the first liquid-absorbing wick channel 5 between the circular hole 7 and the tube body of the evaporation section 1 is 1 mm...

Embodiment 2

[0049] This loop heat pipe with a liquid-absorbing wick flow path is the same as Embodiment 1 except for the following technical features: the thickness of the first liquid-absorbing wick flow path 5 between the circular hole 7 and the tube body of the evaporation section 1 is 0.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com