Thermal management system using micro heat pipe for thermal management of electronic components

a technology of electronic components and management systems, applied in metal-working equipment, semiconductor devices, lighting and heating equipment, etc., can solve the problem of limiting the enhancement of performance and heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The disclosure of U.S. Provisional Application No. 61 / 109,004, filed Oct. 28, 2008, is incorporated by reference herein.

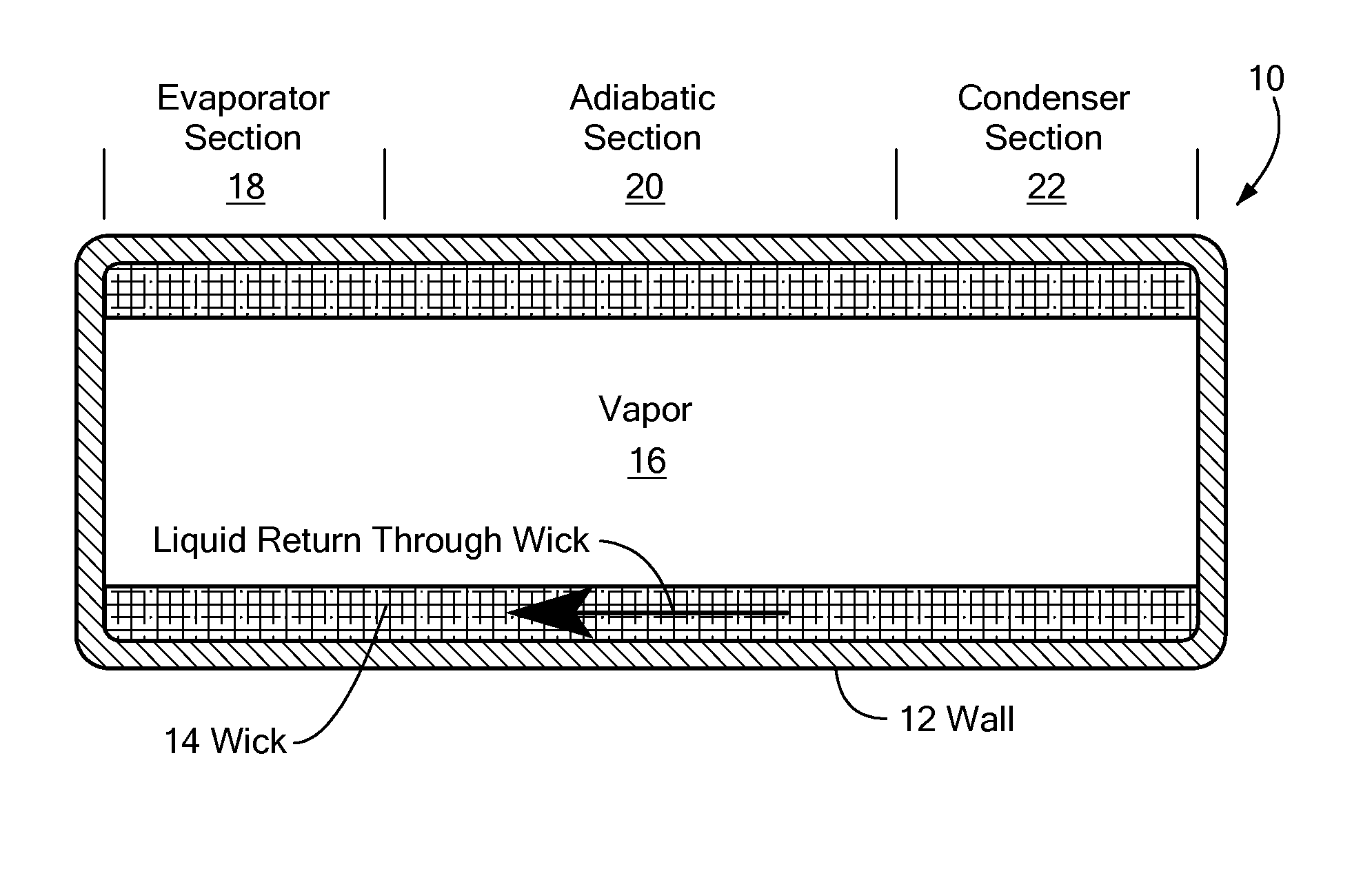

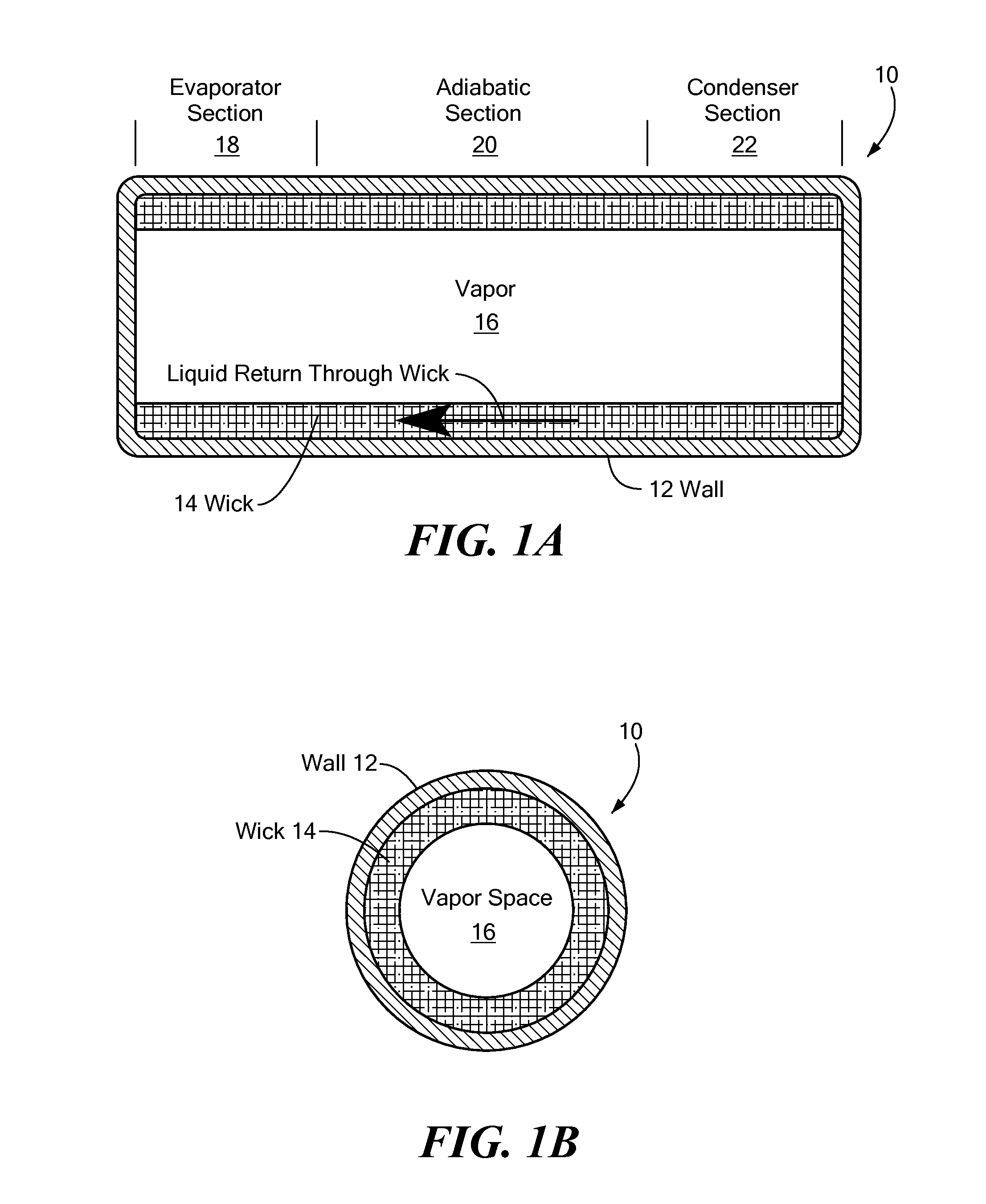

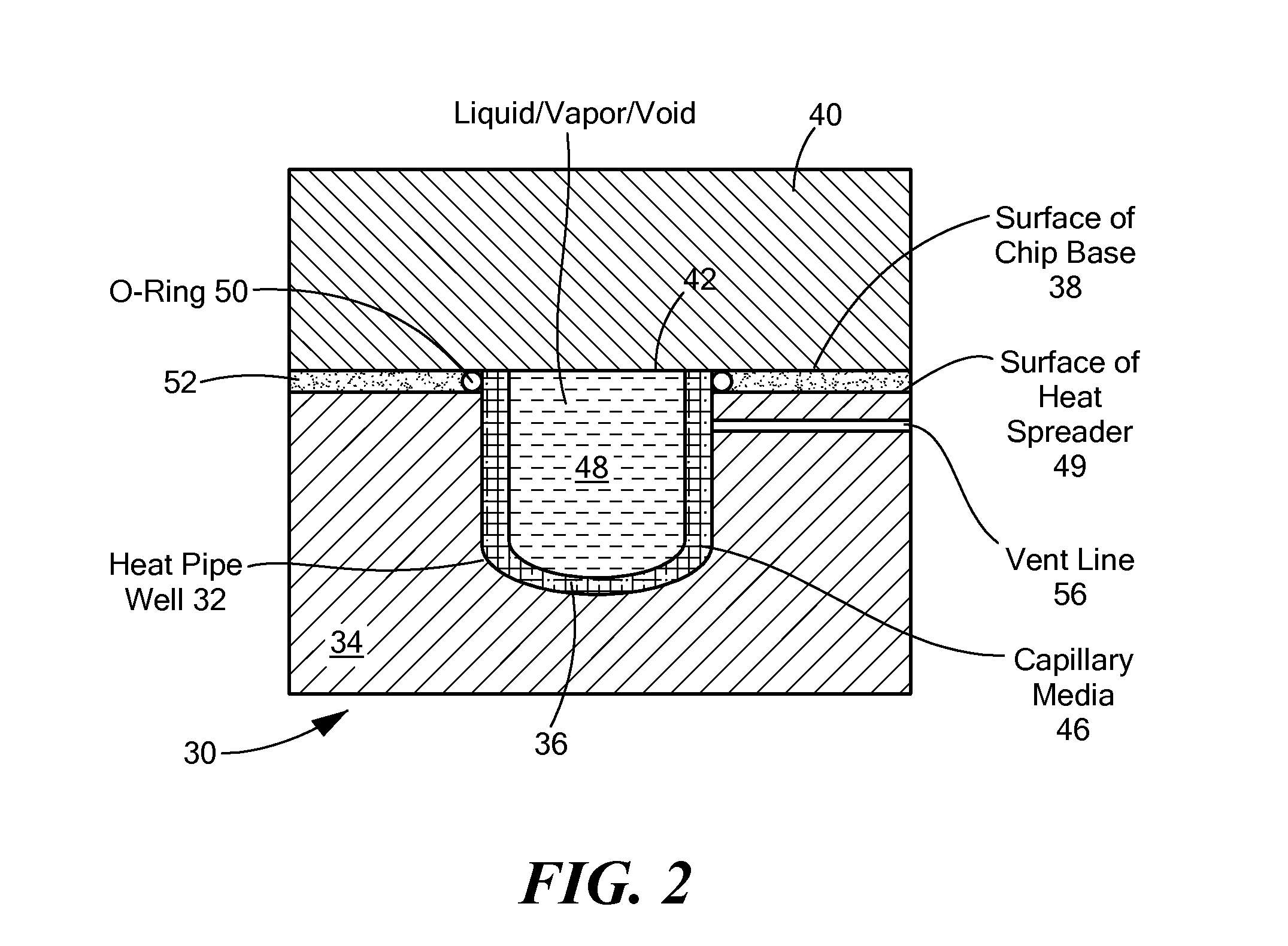

[0015]A bottleneck in transferring heat between components of electronics systems lies at the thermal interfaces between components. Depending on the specific components involved, this thermal interface may be between the die itself and a heat slug or spreader, or a heat slug and heat spreader, or a heat spreader and heat sink. In these cases, an imperfect but comparatively flat surface is presented to be brought into intimate contact with another corresponding flat surface. Except for the die itself, the surfaces are typically metallic, with copper, copper / molybdenum and aluminum being common.

[0016]None of these components has a completely smooth surface, and air pockets exist between the two materials. Air has a very high thermal resistance and hence is a poor heat conductor. To improve the thermal pathway at this interface, thermal compounds are used to fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| heat transfer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com