Miniaturized loop heat pipe

A technology of forming loops and heat pipes, which is applied in the field of heat transfer to achieve the effects of reducing costs, high condensation efficiency, and reducing the length and volume of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail in conjunction with accompanying drawing now.

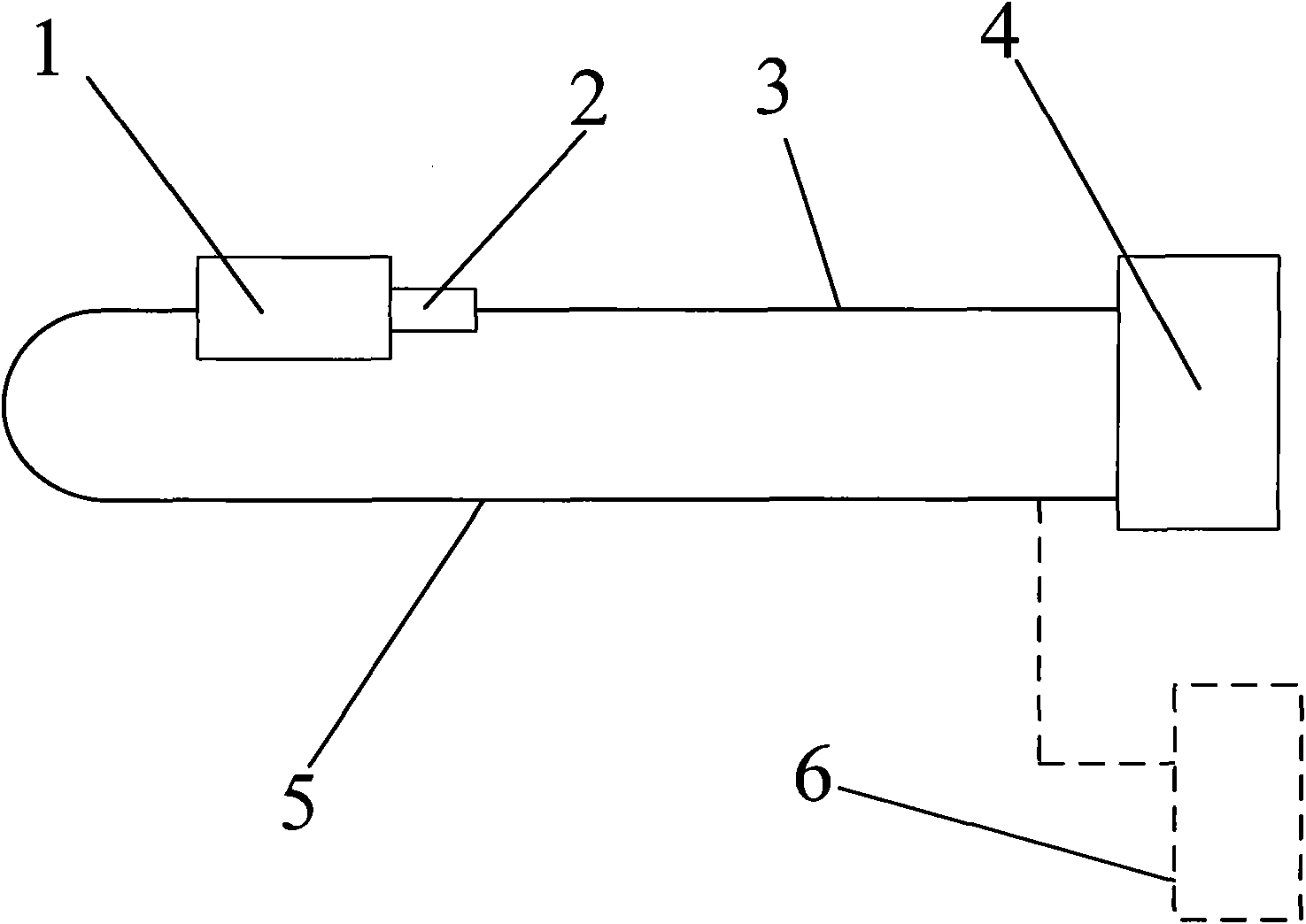

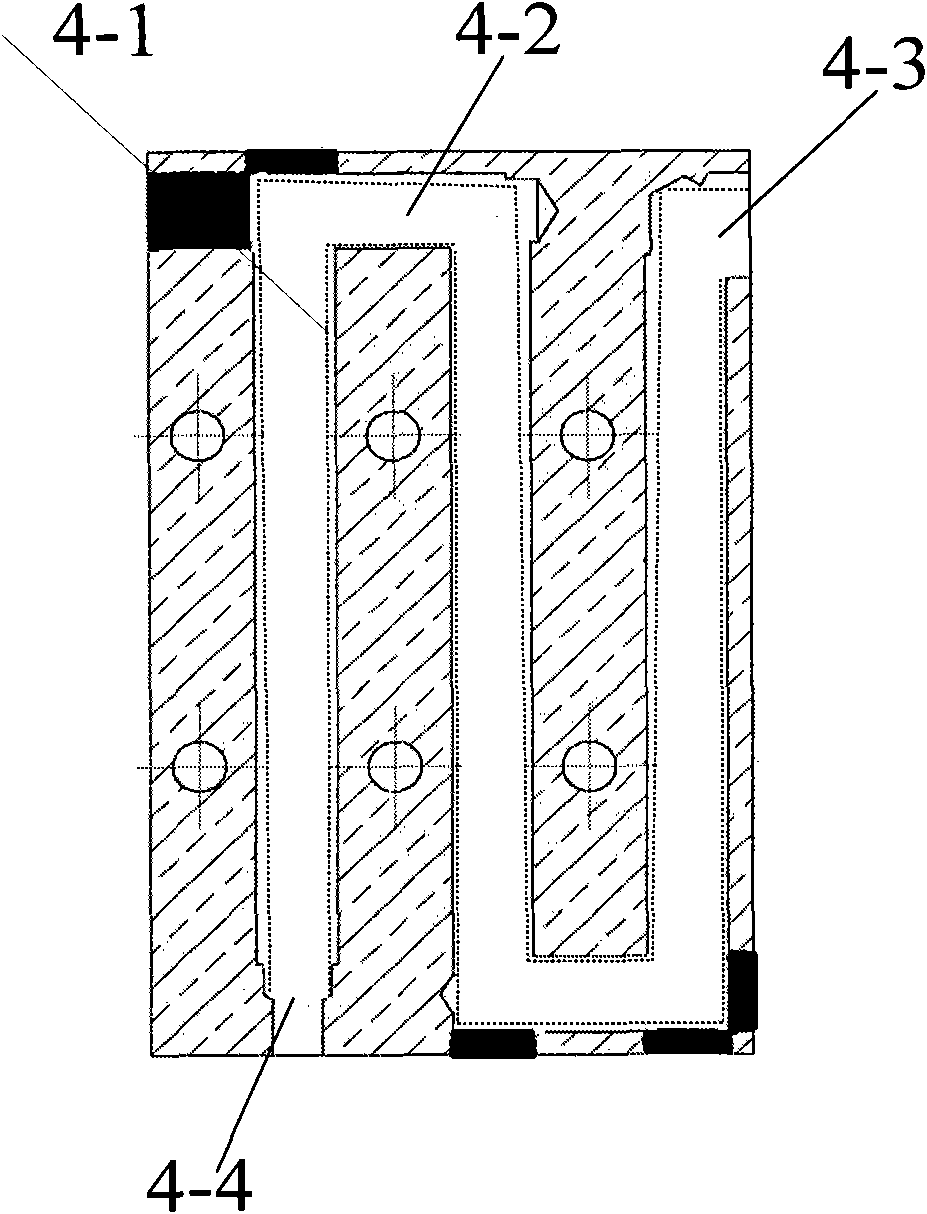

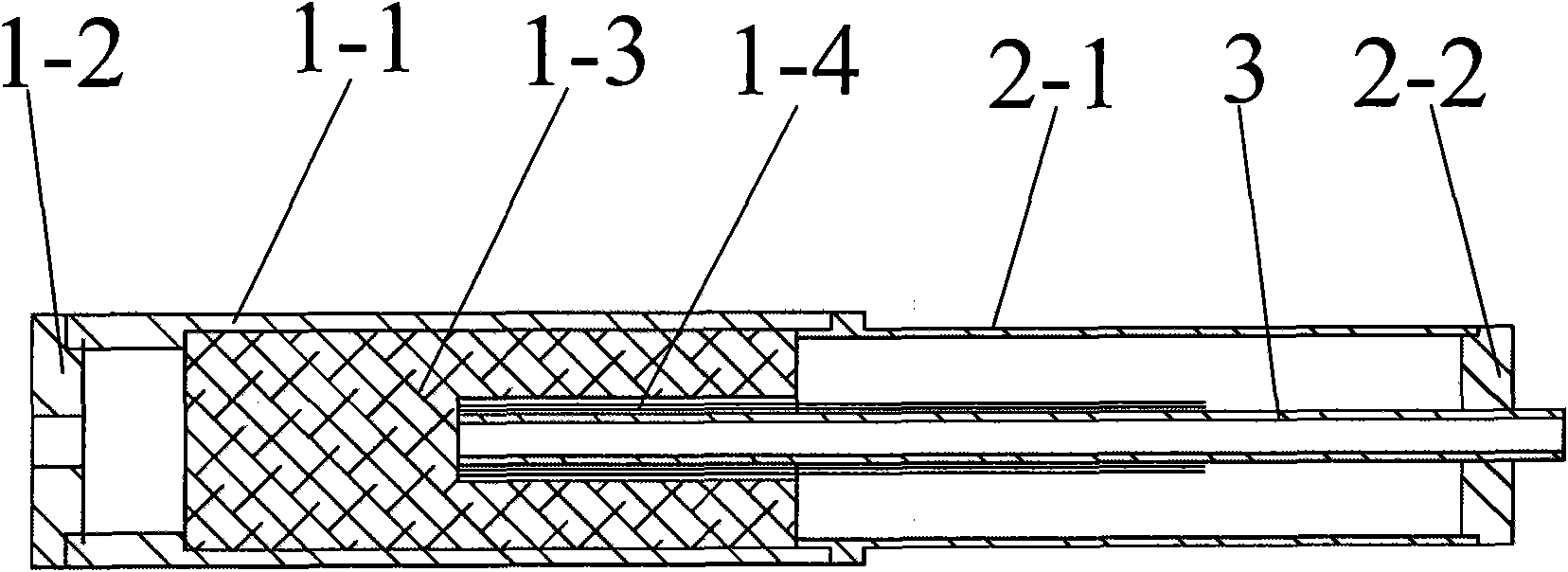

[0023] figure 1 As shown, the miniaturized loop heat pipe of the present invention includes an evaporator 1, a liquid pool 2, and a condenser 4. Using a liquid pipeline 3 and a gas pipeline 5, the above three components are connected in series to form a loop, wherein the evaporator 1 Connected with the liquid pool 2, the interior of the evaporator contains a main liquid suction core 1-3 and a secondary liquid suction core 1-4.

[0024] When the miniaturized loop heat pipe is working at normal temperature, the liquid working medium is directly poured into the liquid pool 2 . Due to the action of the capillary force of the main liquid-absorbing core 1-3, the inside of the main evaporator 1 is filled with liquid. Due to the effect of the circumferential threaded channel 1-3-1 on the outer surface of the main liquid-absorbing core 1-3, the distribution of the liquid will be very u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com