Porous current stabilizing device loop heat pipe

A technology of steady flow device and heat pipe, which is applied in the direction of heat exchanger conduit, heat exchange equipment safety device, heat transfer modification, etc. , to reduce the noise level, improve the steady flow effect, and enhance the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

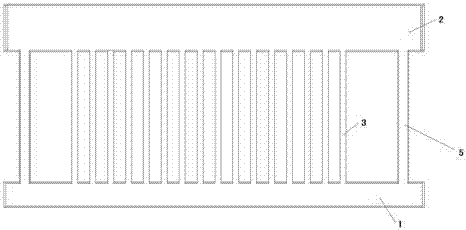

[0050] Such as figure 1 A heat pipe shown includes an evaporation header 1, a condensation header 2, a rising pipe 3 and a return pipe 5, the rising pipe 3 communicates with the evaporation header 1 and the condensation header 2, and the evaporation header 1 Located in the lower part, the condensation header 2 is located in the upper part, the fluid absorbs heat and evaporates in the evaporation header 1, enters the condensation header 2 through the riser 3, condenses after exchanging heat in the condensation header 2, and the condensed fluid Return to the evaporation header 1 through the return pipe 5.

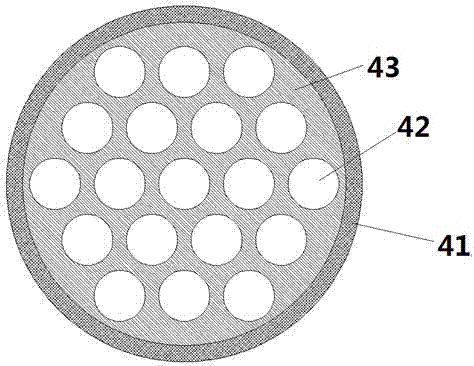

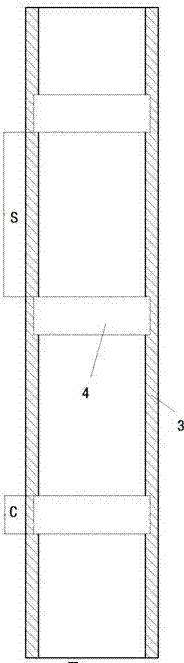

[0051] Such as Figure 4-5 As shown, a porous flow stabilizing device 4 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com