Igniting an underground coal seam in an underground coal gasification process, ucg

A coal seam and fuel technology, applied in the direction of coal gasification, underground mining, manufacture of combustible gas, etc., can solve the problems of explosion, expensive and dangerous installation of ignition wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In the various figures, the same reference numerals refer to the same features.

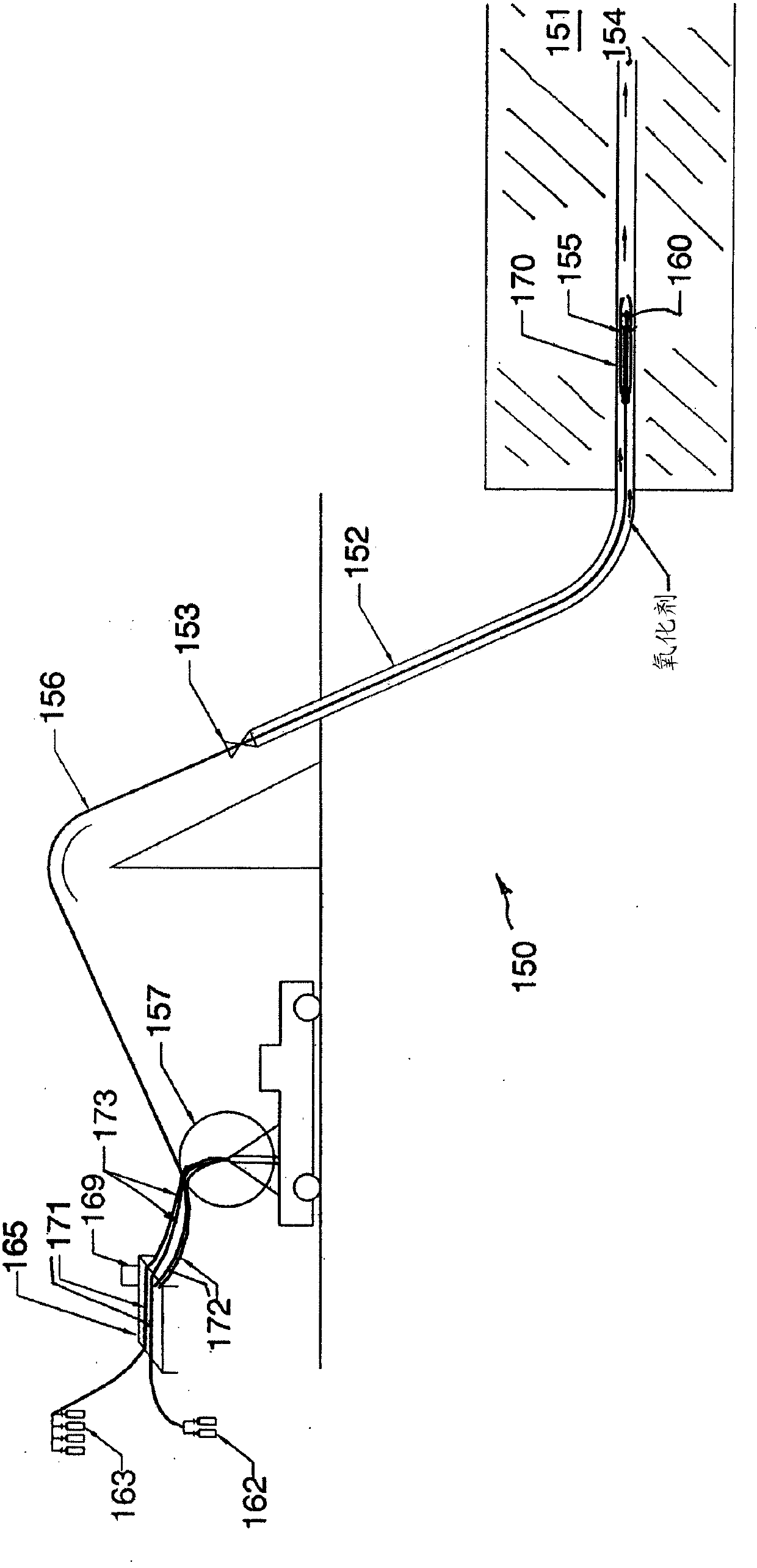

[0083] see first figure 1 , generally depicts an ignition device 150 configured to ignite an underground coal seam 151 . An injection well 152 is shown having a well head 153 and a well channel 154 extending from a heel of the well 152 through the coal seam 151 .

[0084] The ignition device 150 includes an ignition system, a positioning system, a sensor 170 and a controller 165 .

[0085] The ignition system includes an ignition device and an ignition tool 155 for igniting the underground coal seam 151 from within the well passage 154 (or the well lining surrounding the well passage 154).

[0086] The positioning system includes coiled tubing 156 connected to the ignition tool 155 and extendable through the wellhead 153 in the well passage 154 to position the ignition tool 155 at a desired location in the well passage 154. desired location. The positioning system further includes a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com