Method for non-thermal plasma and transition metal concerted catalysis CO2 hydrogenation

A non-thermal plasma, transition metal technology for carbon monoxide, organic chemistry, hydrocarbon production from carbon oxides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example introduces the preparation method of the supported catalyst.

[0025] Take by weighing 3.686 grams of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), dissolved in 9 ml of deionized water to make a red solution. Weigh 3.0 g of SiO 2 (White carbon black) is put into 50 milliliters beakers, and the cobalt nitrate solution that prepares is added dropwise to fills SiO 2 In a beaker, stir while adding dropwise to obtain a pink paste. After the paste was allowed to stand at room temperature for 12 hours, it was dried at 120°C for 12 hours, and fired at 500°C for 3 hours to obtain a Co / SiO mixture with a mass fraction of 20%. 2 catalyst precursor.

Embodiment 2

[0027] This embodiment will provide the plasma reduction of the catalyst precursor, the hydrogenation reaction conditions and the analysis methods and conditions of the inlet and outlet gases, and the CO 2 The effect of the hydrogenation reaction.

[0028] The catalyst precursor (0.88 gram) that obtains in embodiment 1 is loaded into the quartz tube that internal diameter is 8 millimeters, outer diameter is 10 millimeters, and both ends are fixed with quartz wool catalyst precursor, feed hydrogen (flow rate: 80ml / min), under plasma conditions (total input power 50V×0.40A) reduction for 30 minutes to obtain a supported Co catalyst. H 2 The flow rate is adjusted to 50ml / min, and CO is introduced 2 (Flow rate: 10ml / min), adjust the input voltage of the plasma reactor to 45V, the corresponding input current is 0.30A, start CO 2 the hydrogenation reaction.

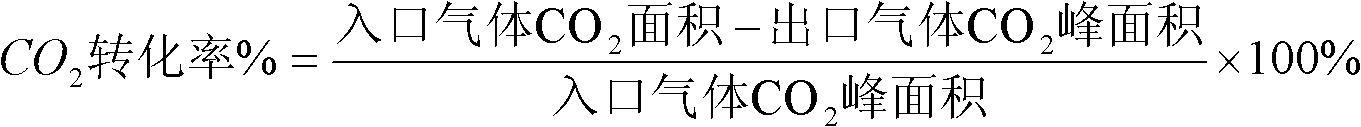

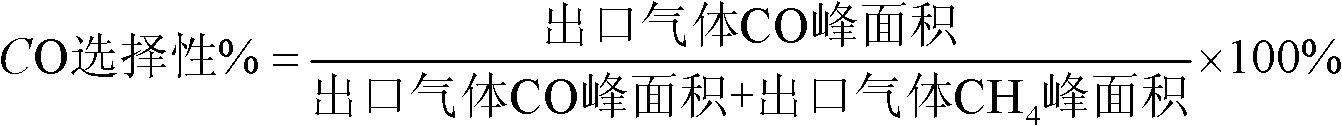

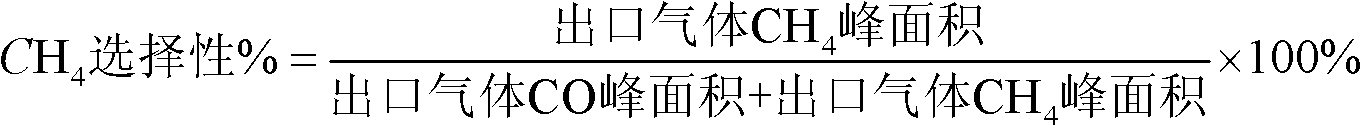

[0029] CO in import and export gas 2 、CH 4 and CO content are detected by gas chromatography (GC-7890), the detector i...

Embodiment 3

[0037] It can be seen from this example that CO can be adjusted by changing the catalyst and reaction conditions 2 Conversion and product selectivity.

[0038] Prepare SiO with reference to the method of embodiment 1 2 Supported Fe and Ru catalysts (metal loadings are 20% by mass), carry out CO according to the reaction steps in Example 2 2 the hydrogenation reaction. Change the input power, and after the reaction system is stable, analyze the outlet gas composition and calculate the reaction conversion rate and product selectivity, the results are shown in the table below. It can be seen that metal catalysts for CO 2 The hydrogenation selectivity has a decisive influence.

[0039]

[0040]

[0041] The above examples illustrate the synergy between dielectric barrier discharge plasma and catalysis to achieve CO under mild conditions. 2 The method and effect of hydroconversion. It is very clear to those skilled in the art that some modifications and improvements can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com