Method for determining coal bed fractures

A technology of cracks and coal seams, applied in the field of underground coal gasification, can solve the problems of unproven, economical and practicability that cannot meet the needs of the industry, high cost, etc., to reduce difficulty, high practicability and economy, and shorten time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

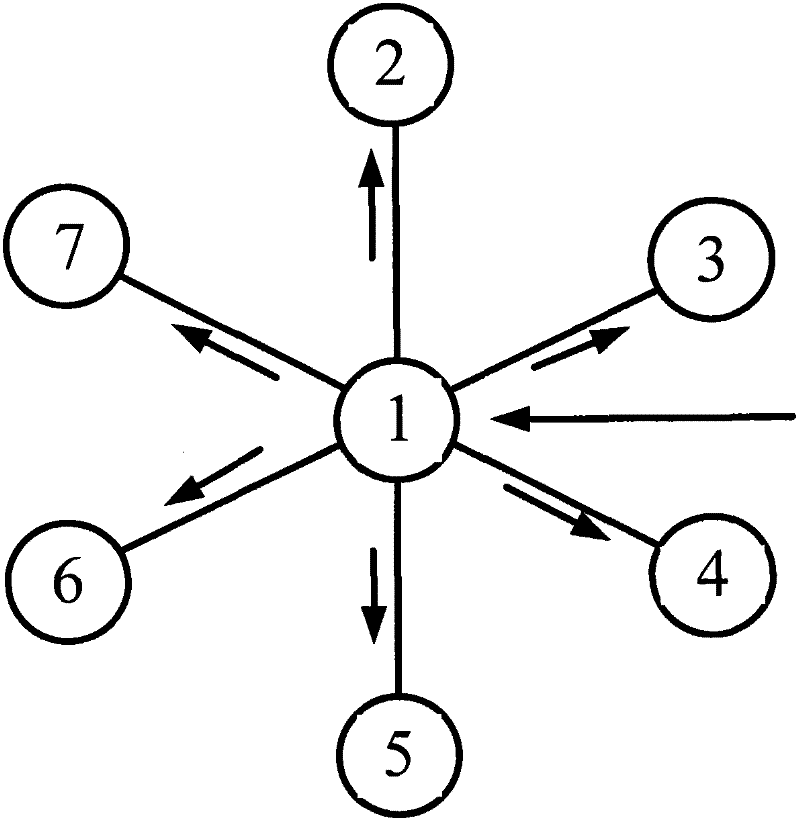

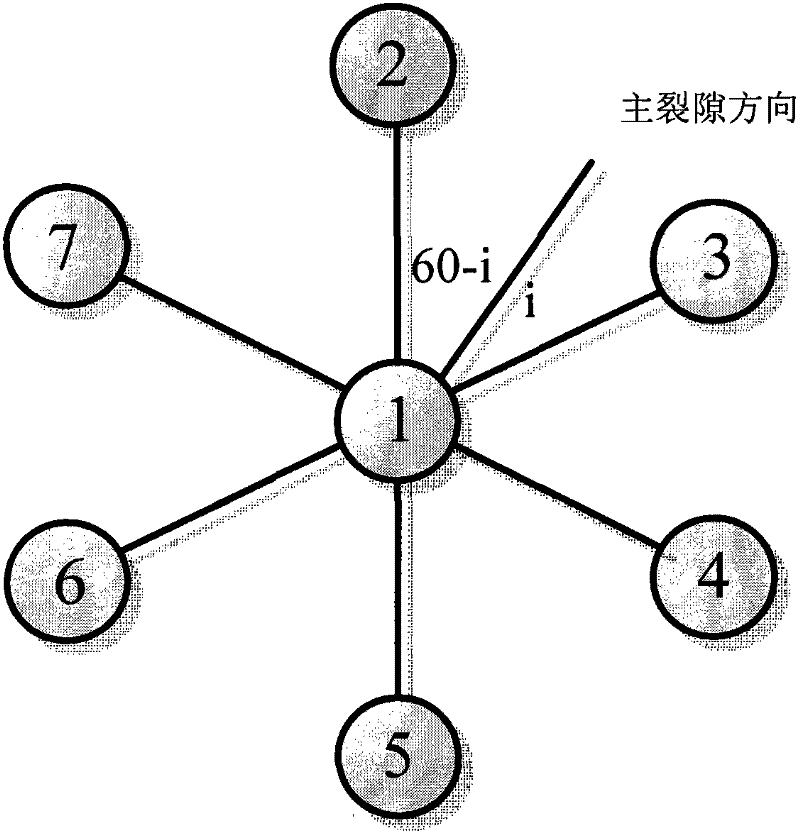

[0054] Such as figure 1 As shown, seven boreholes are included in this example 1. First, a central borehole ① is arranged in the center. Then, on a circular layout line with the central borehole ① as the center and a radius of 15 meters, 6 surrounding boreholes are arranged at intervals of 60° horizontal angle, so that 6 surrounding boreholes are arranged around the central borehole ①. Drill holes ②-⑦.

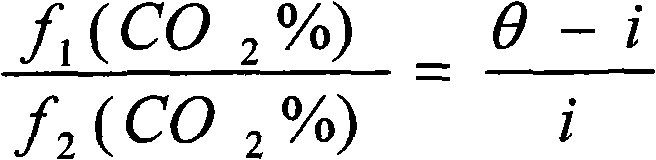

[0055] Then, input high-pressure compressed air (such as figure 1 Indicated by the arrow pointing to the central borehole ①) for high-pressure air fracturing. The high-pressure compressed air input into the central borehole ① will overcome the resistance of the underground coal seam, pass through the underground coal seam, and flow out of the surrounding boreholes ②-⑦ with different flow rates (such as figure 1The arrows from the central drilling ① to each surrounding drilling ②-⑦ are shown). Monitor and measure the gas flow and gas components discharged from the surround...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com