Passage formation method for underground coal gasification

An underground gasification and gasification channel technology, which is applied in coal gasification, underground mining, earth drilling and mining, etc., can solve the problems of being easily affected by groundwater, slow flame moving speed, and poor channel directionality, so as to shorten the penetration period, Reduce construction difficulty and enhance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

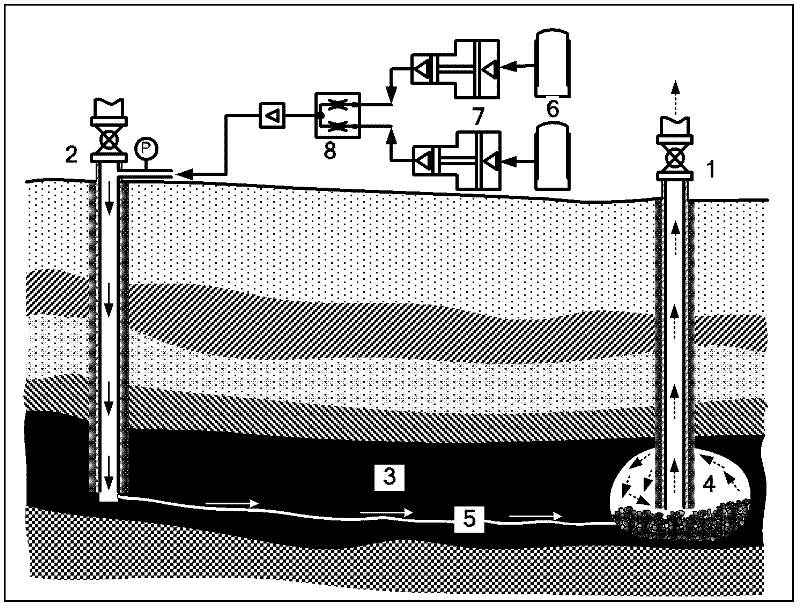

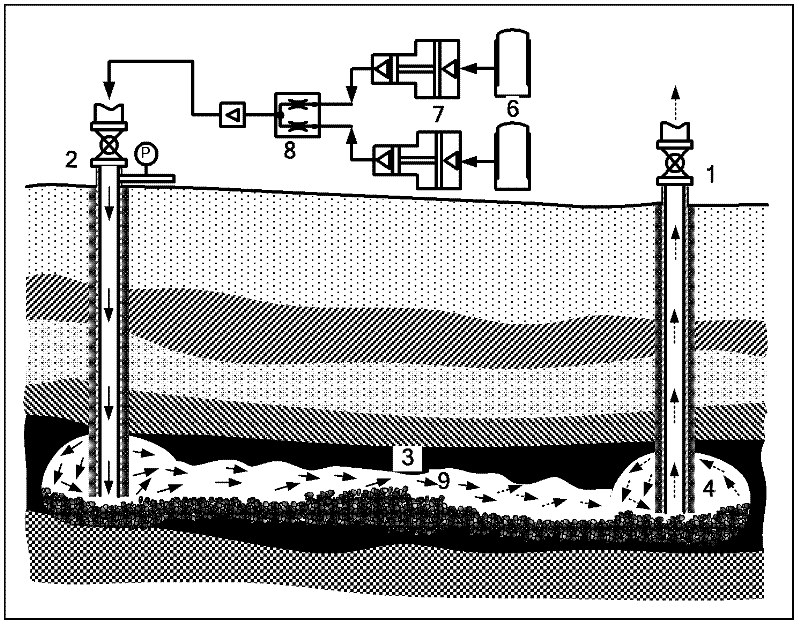

[0095] Such as Figure 1A , Figure 1B As shown, the existing vertical borehole 1 has a directional borehole 2 constructed at a distance of 200m from the borehole 1. It is planned to use the method of the present invention to establish a gasification channel and complete the gasification of coal in the area. The implementation process is as follows:

[0096]The fire zone 4 is established in the coal seam 3 at the bottom of the borehole 1 by means of electric ignition, and the temperature of the fire zone is controlled by adjusting the composition and flow rate of the gasification agent according to the water inflow of the coal seam and the gas outlet temperature. The temperature of the fire zone is generally not lower than that of the coal seam Auto-ignition temperature.

[0097] After the fire zone is established at the bottom of hole 1, directional drilling technology is used to construct a directional channel 5 along the coal seam via drill hole 2, and directly drill throug...

Embodiment 2

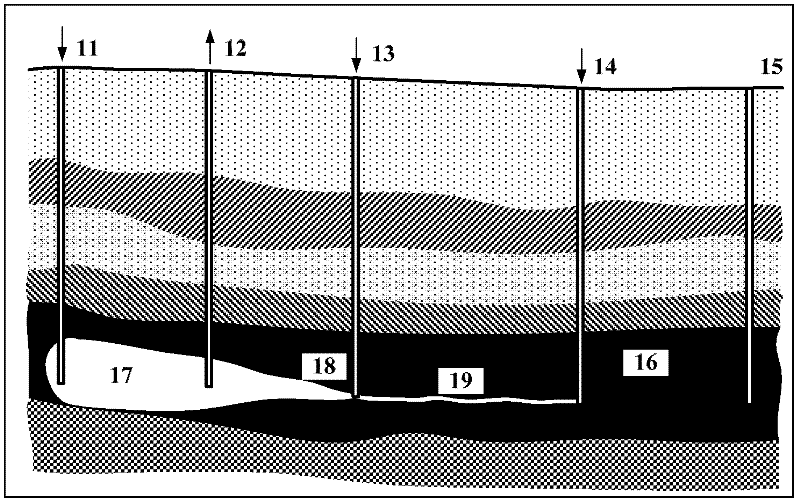

[0102] Such as figure 2 As shown, in the case of an underground coal gasification through-site, a plurality of boreholes 11, 12, 13, 14, 15 are provided, each of these boreholes is generally opened vertically, and these Drill holes along the horizontal direction ( figure 2 The left and right directions in the middle) are distributed at intervals with unequal intervals. The lower ends of each borehole deep into the underground coal seam area need to be connected in order to form the gasification channel required by the subsequent underground coal gasifier, among which, such as figure 2 As shown in the lower left of , the lower ends of the boreholes 11 and 12 have been penetrated (by air fire penetration in the prior art) and a gasification passage 17 in a substantially horizontal direction has been formed. It is planned to adopt the method of the present invention to continue the penetrating operation on the lower ends of the boreholes 12, 13, 14, and 15, and to accelerate...

Embodiment 3

[0114] Figure 3A , Figure 3B Shown is an example of an existing underground gasifier layout in which multiple vertical boreholes have been drilled. Select the lower end coal seam of borehole 22 to ignite, and form the fire area 21 of borehole 22, the lower end coal seam of existing borehole 23, 24, 25 needs to be penetrated, and after the penetration is completed, these vertical boreholes are used as vents. Boreholes 23, 24, and 25 are all vertical boreholes. The casing bottoms of these vertical boreholes are located 0.5m above the coal seam floor, and the borehole centers are basically on the same straight line (such as figure 2 Shown by the dotted line in the horizontal direction in A), wherein the spacing between the boreholes 23, 24, 25 is about 50m, and the spacing between the drilling holes 22, 23 is also about 50m. As described below, the directional drilling technology is used to penetrate the boreholes 23, 24, 25 along the coal seam to complete the docking with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com