Coal-bed gas thermal cavity completion method

A technology of coalbed methane and caves, which is applied in coal gasification, drilling equipment and methods, and earthwork drilling and mining, etc. It can solve the problems of high frequency of wellbore sand fishing operations, easy collapse of exposed coal seams, and wellbore damage, etc., and achieves good results and coal seams. Stable and not easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

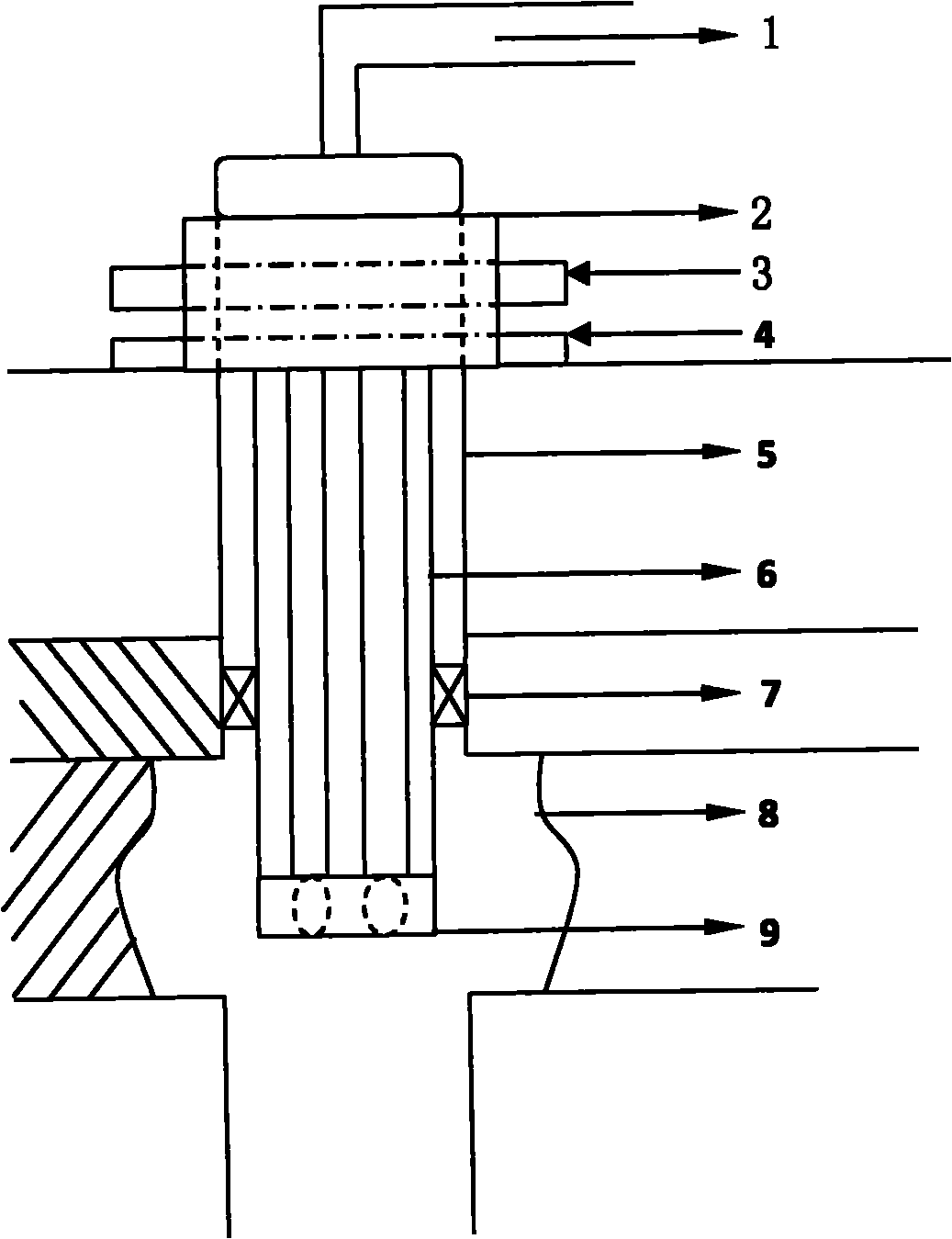

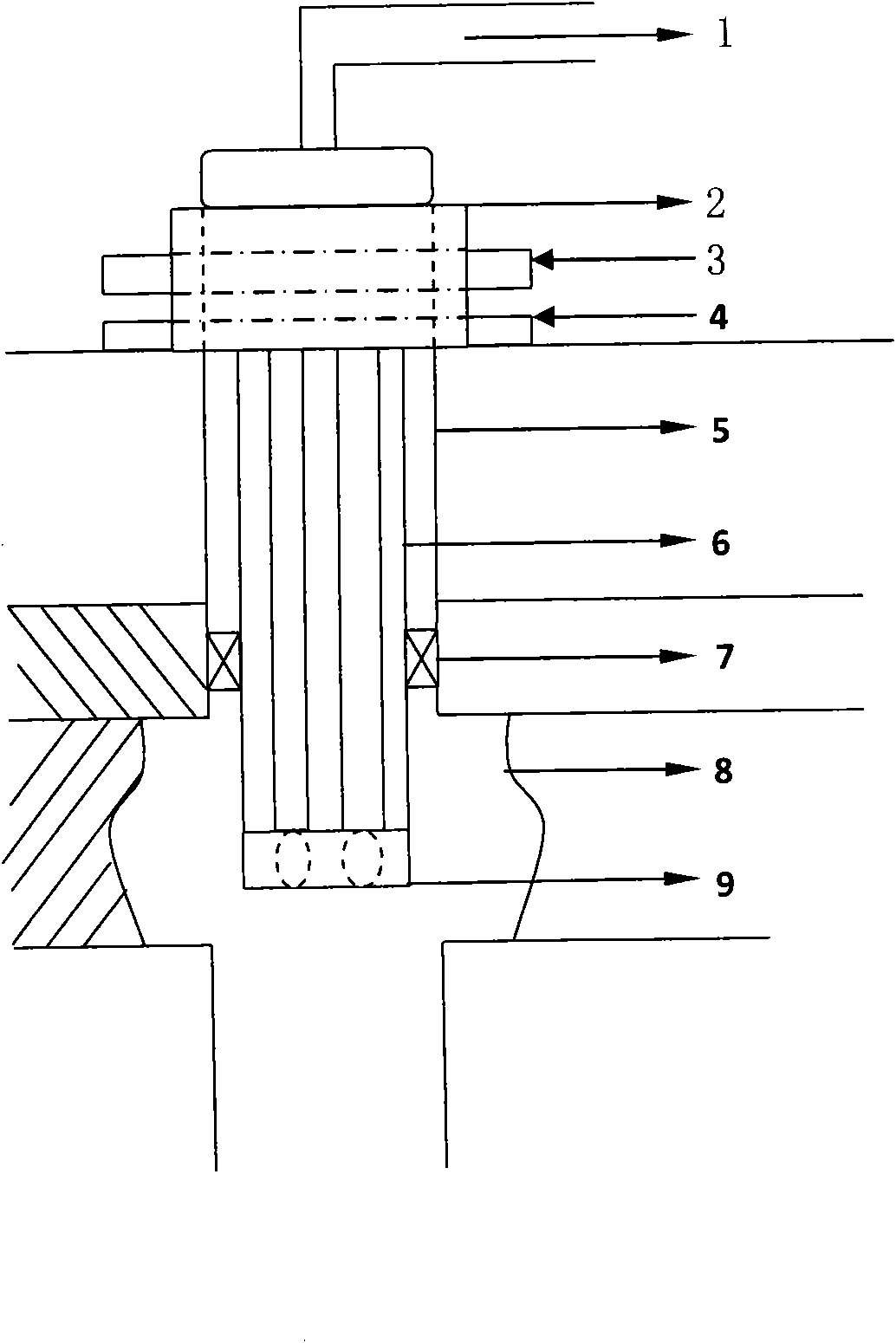

[0023] see figure 1 As shown, the coalbed methane cave thermal well completion method can be implemented according to the following steps:

[0024] (1) Carry out high-temperature cement casing cementing at the top of the coal seam;

[0025] (2) After drilling to 50-80 meters below the coal seam, the coal seam section is reamed and completed;

[0026] (3) Remove coal powder in the shaft;

[0027] (4) Run the combined thermal completion string to the middle of the cave;

[0028] (5) Inject silane and oxygen, and the cave part starts to burn, heating the coal seam;

[0029] (6) When the temperature is higher than 600°C, determine whether to stop supplying silane according to the composition detection results of the flowback gas;

[0030] (7) When the temperature rises to 1500°C, the supply of oxygen is stopped.

[0031] In the step (1), the high temperature-resistant cement casing is cemented at the top 15-20 meters of the coal seam.

[0032] In the step (4) of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com