Igniting an underground coal seam in an underground coal gasification process, ucg

a coal gasification process and underground coal seam technology, applied in the direction of combustible gas production, fluid removal, insulation, etc., can solve the problems of teb or silane use, high cost and time consumption, and inability to produce combustion fronts at combustion zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

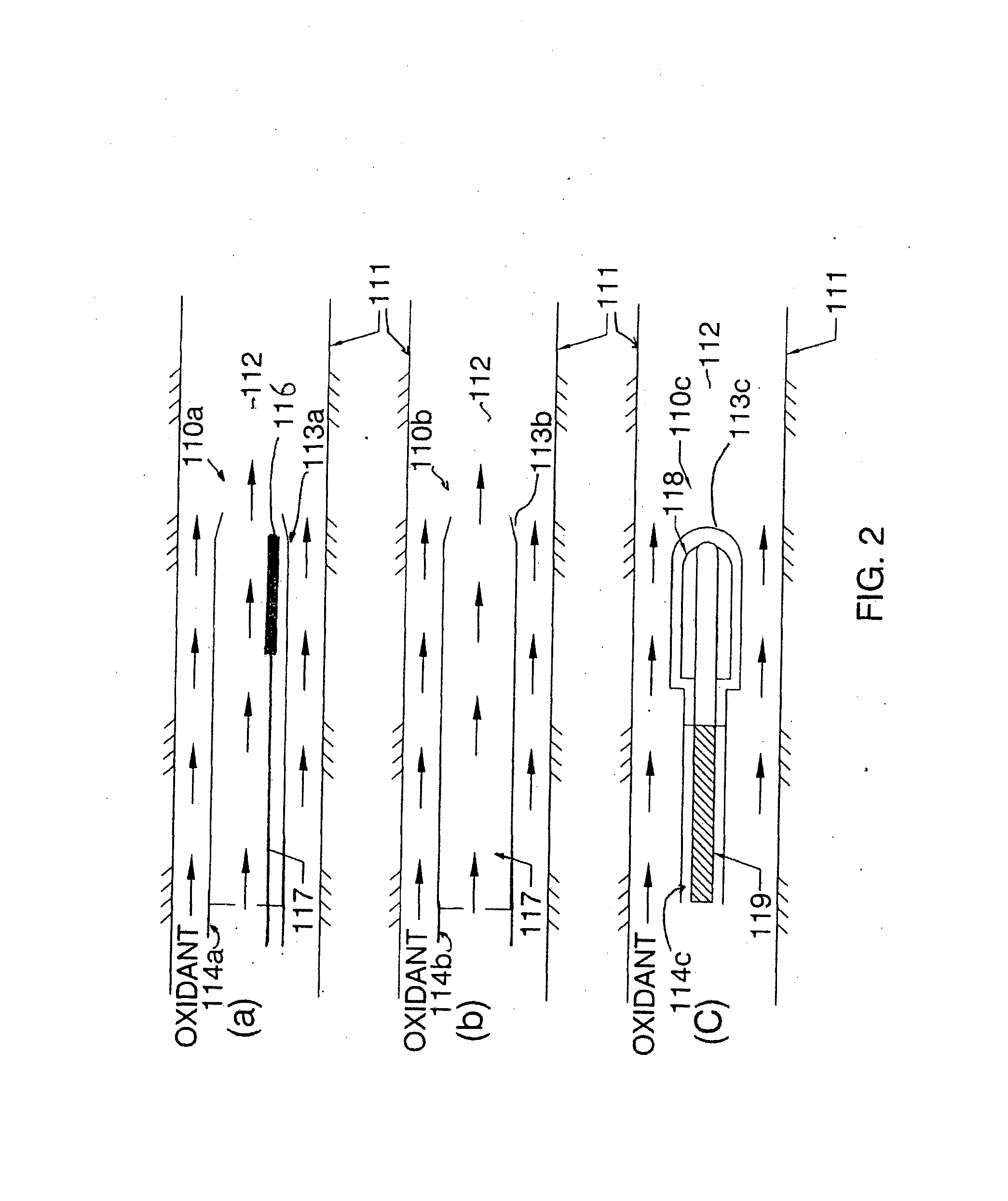

[0082]In the figures, like reference numerals refer to like features.

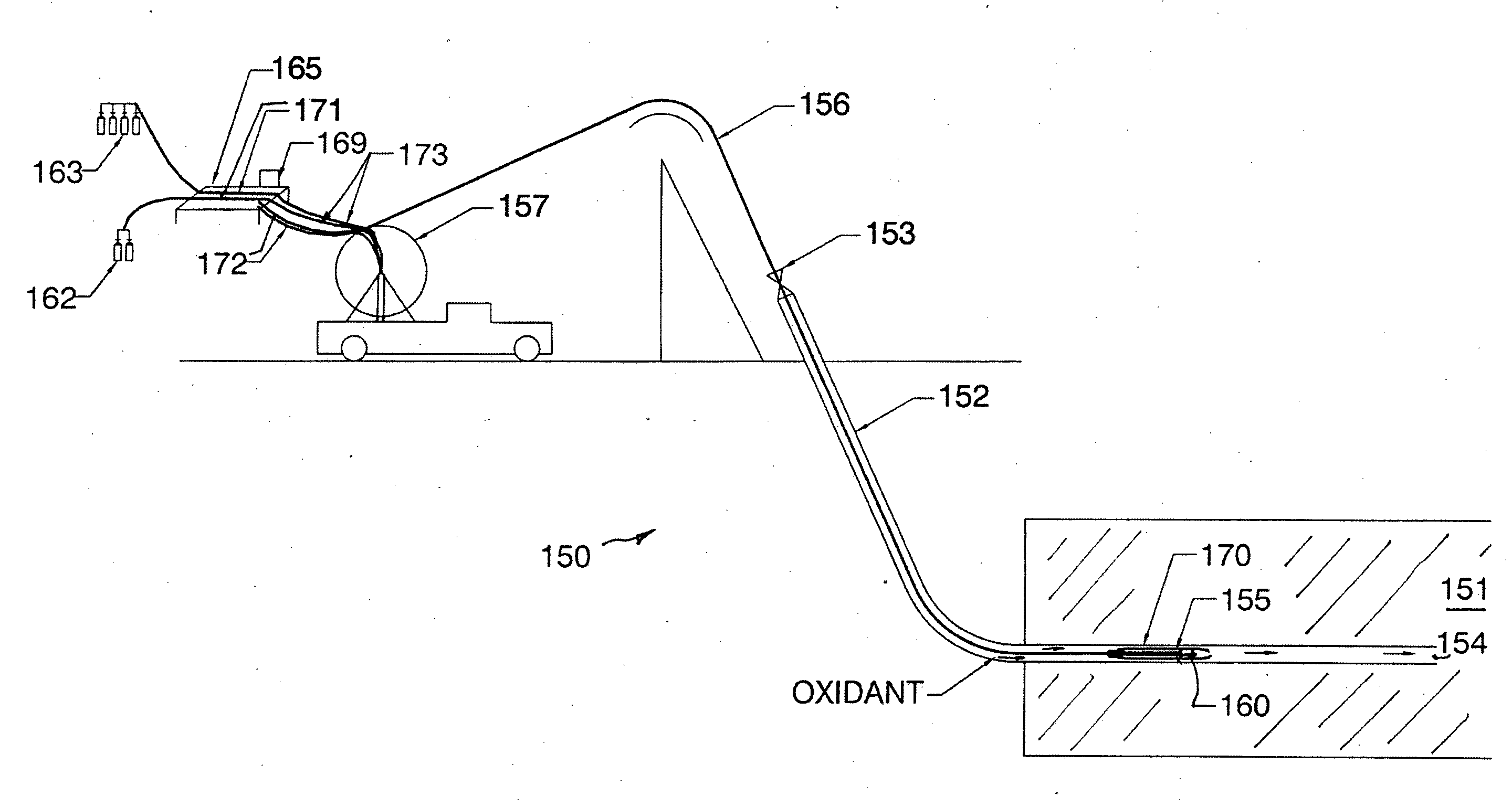

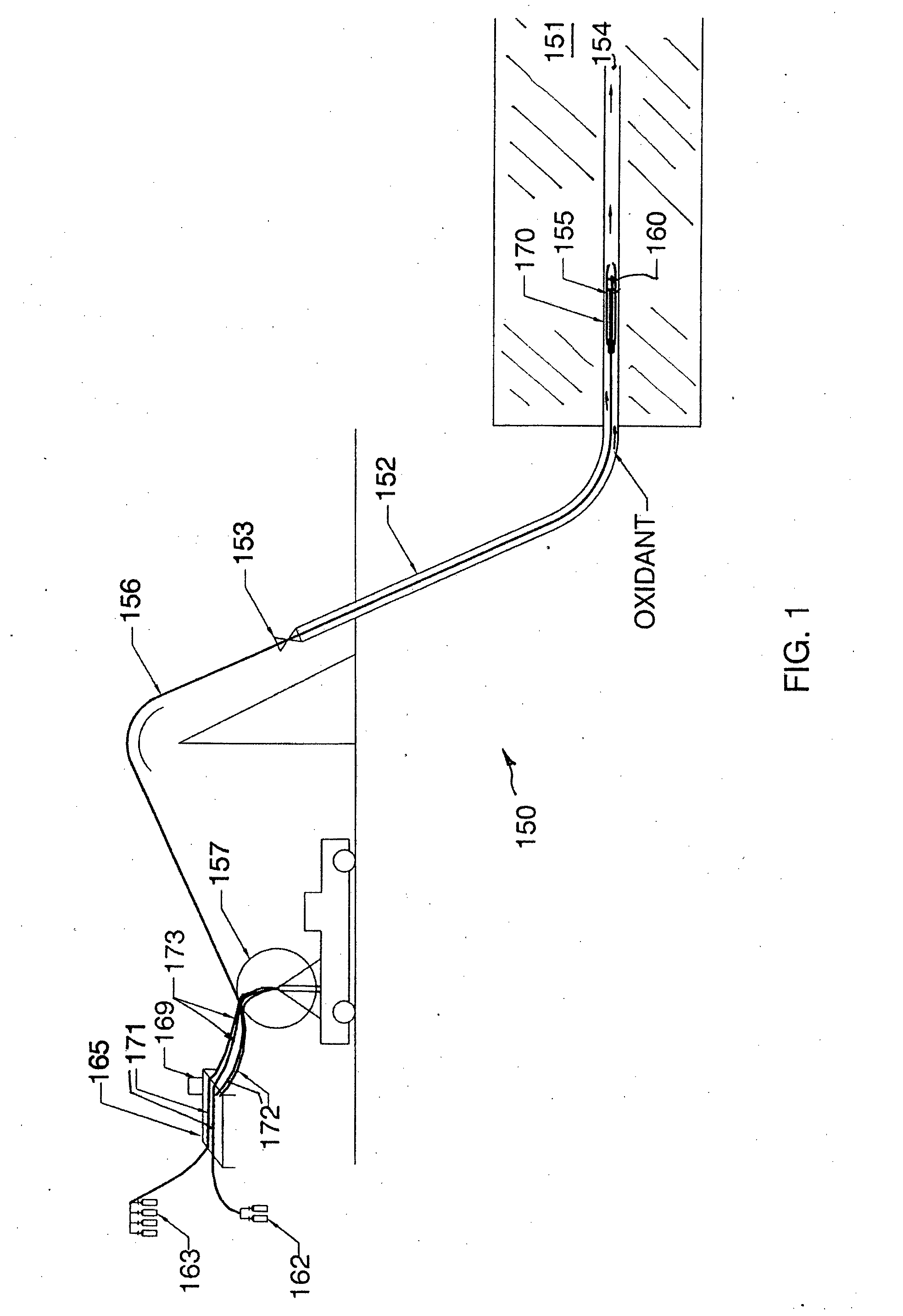

[0083]Referring first to FIG. 1, there is generally depicted an ignition apparatus 150 configured to ignite an underground coal seam 151. There is shown an injection well 152 having a well head 153 and a well channel 154 extending from a heel of the well 152 through the coal seam 151.

[0084]The ignition apparatus 150 comprising an ignition system, a positioning system, a sensor 170 and a controller 165.

[0085]The ignition system comprises ignition means and an ignition tool 155 for igniting the underground coal seam 151 from within the well channel 154 (or well liner encasing the well channel 154).

[0086]The positioning system comprises coiled tubing 156 connected to the ignition tool 155 and extendible through the well head 153 within the well channel 154 to position the ignition tool 155 at a desired location within the well channel 154. The positioning system further comprises a spool 157 for transporting and dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com