Vertical shaft and horizontal shaft joint ignition method in underground coal gasification mining

An underground gasification and horizontal well technology, applied in coal gasification, underground mining, special mining, etc., can solve the problems of small underground space, difficult ignition, long ignition time, etc., to save time, increase ignition success rate, and expand storage. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

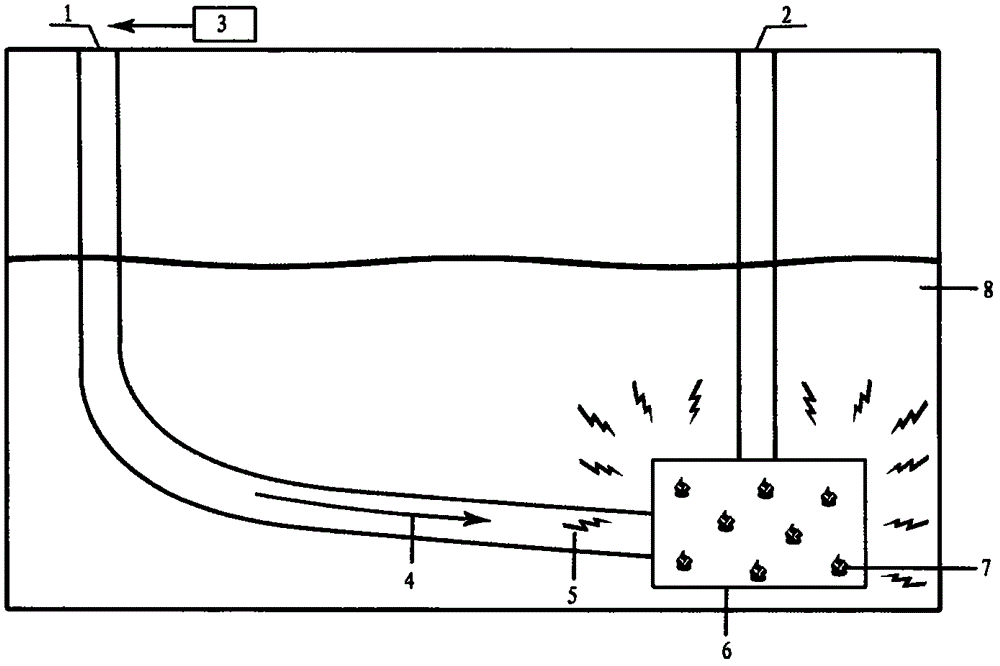

Embodiment 1

[0018] A method for combined ignition of vertical wells and horizontal wells in underground coal gasification mining, comprising the following steps: Step 1. Carrying out coal field exploration, drilling vertical wells (2) and horizontal wells (1), and the horizontal well (1) is at the bottom of the coal seam (8) 65cm; step 2. Drill out a hole with a diameter of 85cm and a length of 2m at the expected ignition position with the drill bit. After reaming, the large hole is 25cm away from the underlying stratum; the connection between the wellbore and the coal seam (8) uses a perforating gun method of perforating; step 3. carry out high-pressure hydraulic fracturing to the coal seam (8), and the fracturing range is 12m; step 4. inject a weight ratio of 1:2 ammonium nitrate and chlorine 1 ton of mixture composed of potassium chloride is injected into 17000 square meters of air, and then 0.5 ton of oxalic acid is injected; step 5. after step 4 is completed, inject oxygen-enriched pi...

Embodiment 2

[0020] A method for combined ignition of vertical wells and horizontal wells in underground coal gasification mining, comprising the following steps: Step 1. Carrying out coal field exploration, drilling vertical wells (2) and horizontal wells (1), and the horizontal well (1) is at the bottom of the coal seam (8) 55cm place; Step 2. drill out a hole with a diameter of 80cm and a length of 2.5m at the expected ignition place with the drill bit. After the hole is expanded, the large hole is 22cm away from the lower overburden; the connection between the wellbore and the coal seam (8) adopts perforation Gun mode perforation; Step 3. Carry out high-pressure hydraulic fracturing to the coal seam (8), and the fracturing range is 11m; Step 4. Inject the ammonium nitrate and A mixture of 1.5 tons of potassium chloride is injected into 18,000 square meters of air, and then 0.6 tons of oxalic acid is injected; step 5. After step 4 is completed, inject oxygen-enriched pilot gas (4) into t...

Embodiment 3

[0022] A method for combined ignition of vertical wells and horizontal wells in underground coal gasification mining, comprising the following steps: Step 1. Carrying out coal field exploration, drilling vertical wells (2) and horizontal wells (1), and the horizontal well (1) is at the bottom of the coal seam (8) 70cm; step 2. Drill out a hole with a diameter of 85cm and a length of 3m at the expected ignition position with the drill bit. After reaming, the large hole is 30cm away from the underlying stratum; the connection between the wellbore and the coal seam (8) uses a perforating gun method perforation; step 3. carry out high-pressure hydraulic fracturing to the coal seam (8), and the fracturing range is 13m; step 4. inject the ammonium nitrate and chlorine 2 tons of the mixture of potassium chloride, then inject 20,000 square meters of air, and then inject 0.8 tons of oxalic acid; Step 5. After step 4 is completed, inject oxygen-rich pilot gas (4) into the coal seam (8) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com