Method, device and system for determining internal combustion mined-out areas of underground coal gasification furnace

A technology for underground gasification and burn-out areas, applied in coal gasification, underground mining, construction, etc., can solve problems such as gas leakage, excessive movement of coal and rock layers in burn-out areas, and environmental pollution, and achieve real-time monitoring, realization of scope and The effect of extending the law

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

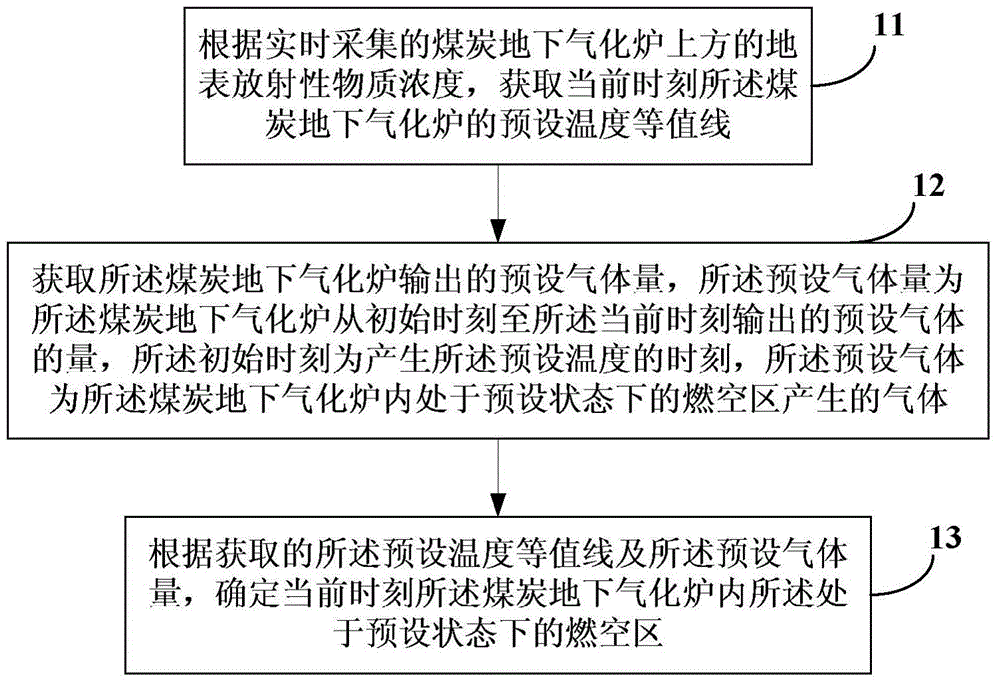

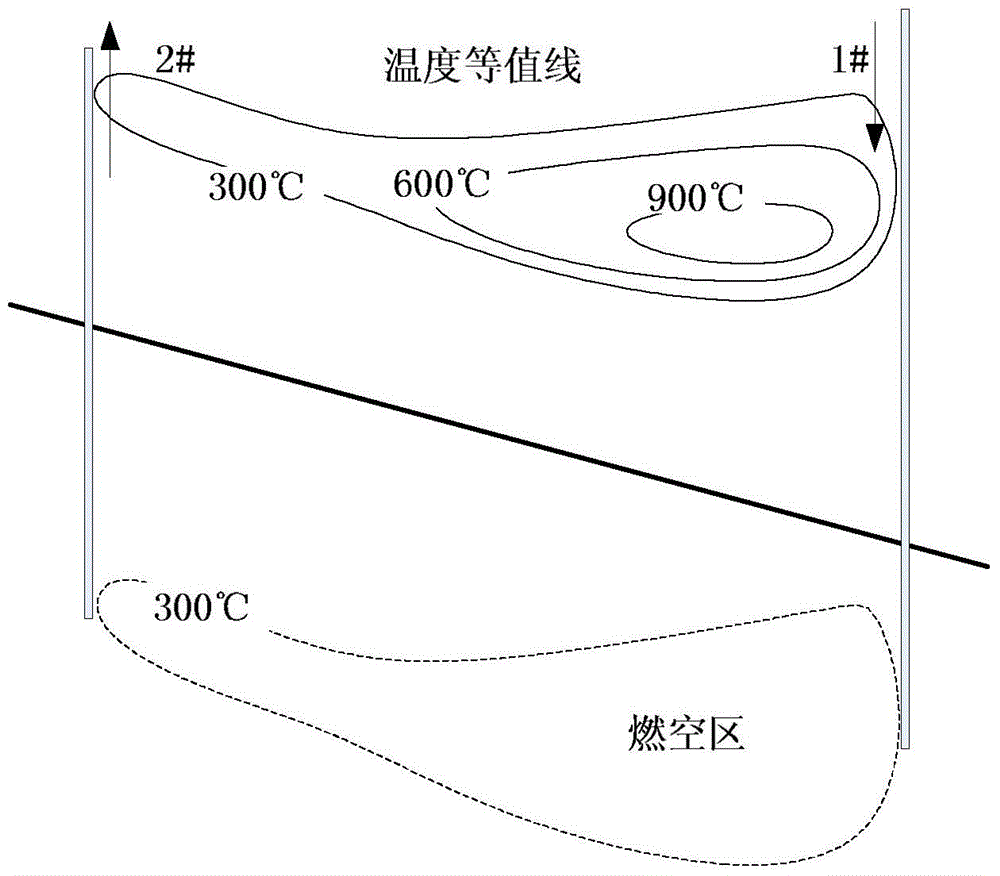

[0028] figure 1 It is a flow chart of a method for determining the internal combustion void area of an underground coal gasifier provided by an embodiment of the present invention. Such as figure 1 As shown, the method for determining the internal combustion void area of an underground coal gasifier includes: step 11 to step 13.

[0029] In step 11, according to the surface radioactive material concentration above the underground coal gasifier collected in real time, the preset temperature contour of the underground coal gasifier at the current moment is obtained.

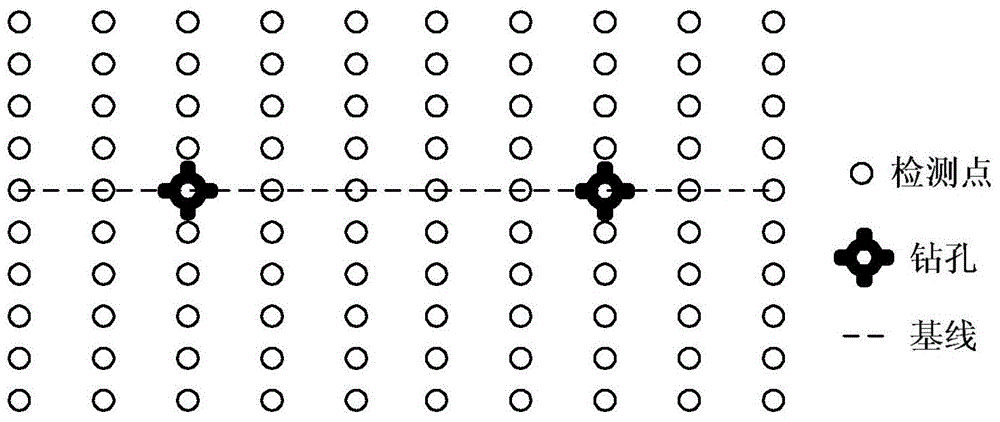

[0030] For example, before the underground coal gasification furnace gasifies the coal seam, according to the needs of the underground gasification site, enough reasonable detection points can be arranged on the ground directly fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com