Real-time monitoring method for two-dimensional planar temperature field of underground coal gasification furnace

An underground gasification, two-dimensional plane technology, used in temperature measurement of moving fluids, thermometers, thermometers using directly heat-sensitive electrical/magnetic components, etc., can solve harsh chemical environments, instrument installation, and long detection periods question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

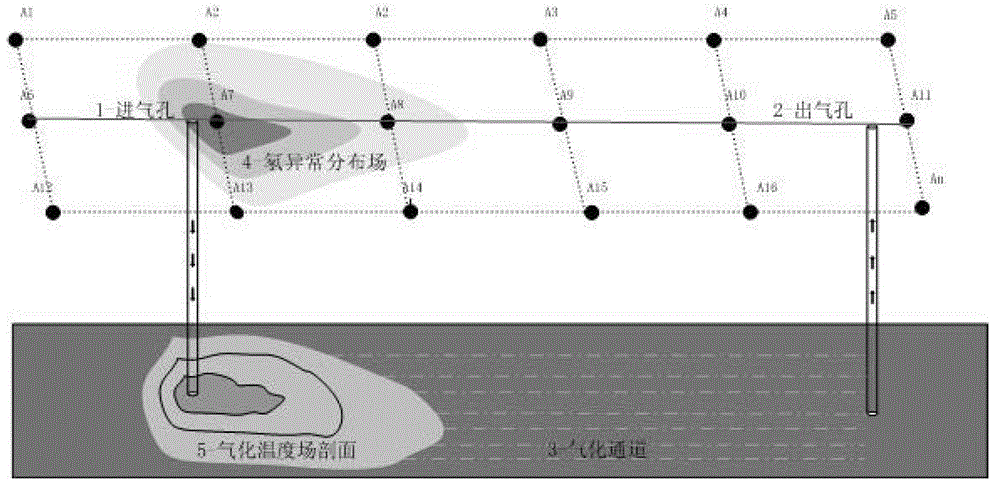

[0024] Such as figure 1 As shown, the underground coal gasification process is to drill holes from the ground to the coal seam, one of which is the air inlet hole 1, and the other hole is the air outlet hole 2, and coal seam fracturing and other methods are used to form gas in the two holes. Channel 3. After ignition, the gasification agent (air, water vapor, oxygen-enriched air, etc.) The gas is transported to the ground from the vent hole 2.

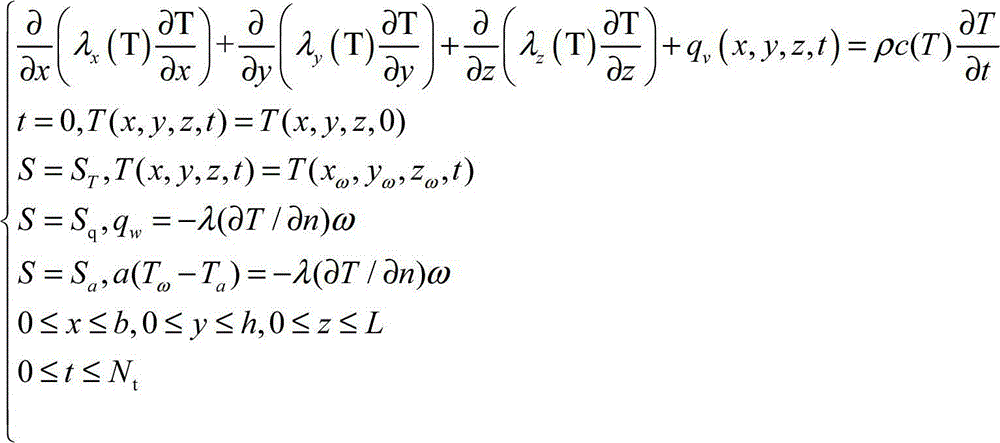

[0025] In the process of underground coal gasification, as the chemical reaction continues, a dynamic temperature field (500-1300°C) is formed in the coal seam. The temperature field is not only the basis of all reactions, but also indirectly reflects the combustion state of the gasifier. Therefore, measuring the temperature field distribution in the gasifier is crucial to the stable control of underground gasification. Therefore, it is particularly important to use related technologies and methods to determine the distribution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com