Cement composition and application thereof

A cement composition and composition technology, applied in the direction of drilling composition, coal gasification, chemical instruments and methods, etc., can solve the problems of poor high temperature resistance, easy cracking or falling off, etc., and achieve excellent high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

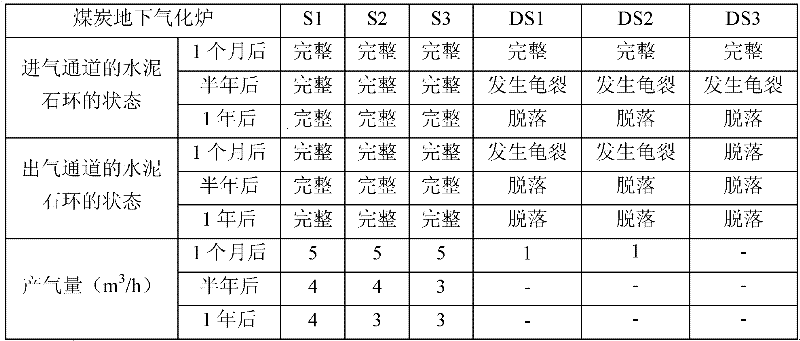

Embodiment 1

[0071] This example is used to illustrate the cement composition of the present invention and its application.

[0072] (1) Preparation of cement slurry

[0073] The particle diameter of 15 parts by weight is about 150 mesh quartz sand (SiO 2 The content is about 96% by weight), the particle diameter of 15 parts by weight is about 200 mesh quartz sand (SiO 2 content is about 98% by weight), 20 parts by weight of fly ash and 2 parts by weight of water glass are mixed. Then, the obtained mixture was mixed with 100 parts by weight of G-grade oil well cement (purchased from Shandong Huayin Special Cement Co., Ltd.) and 55 parts by weight of water to obtain cement slurry A3. The density of the cement slurry A3 measured by the specific gravity method is 1.75g / cm 3 .

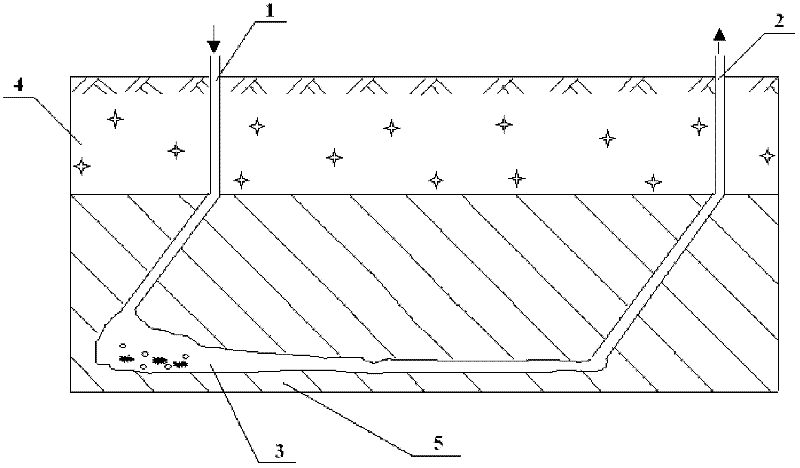

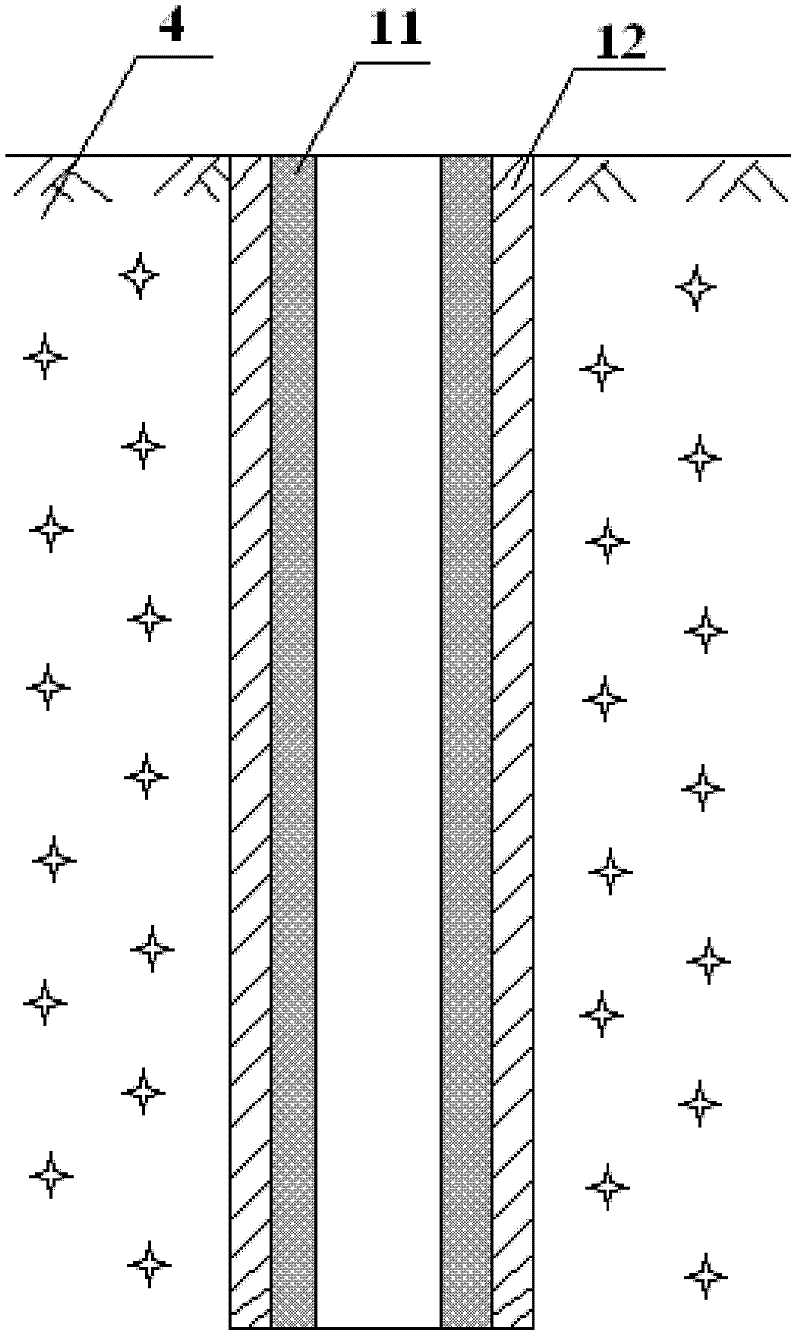

[0074] (2) Preparation of coal underground gasifier

[0075] Two wells with diameters of 311 mm and 215.9 mm were drilled in the formation all the way to the coal seam, the distance between the axes of the two wel...

Embodiment 2

[0077] This example is used to illustrate the cement composition of the present invention and its application.

[0078] (1) Preparation of cement slurry

[0079] The particle diameter of 8 parts by weight is about 120 mesh quartz sand (SiO 2 Content is about 96% by weight), the particle diameter of 12 parts by weight is about 180 mesh quartz sand (SiO 2 The content is about 98% by weight), 25 parts by weight of floating beads (purchased from Hebei Xingtai Hongtai Floating Bead Factory) and 2 parts by weight of calcium chloride. Then, the obtained mixture was mixed with 100 parts by weight of G-grade oil well cement (purchased from Shandong Huayin Special Cement Co., Ltd.) and 60 parts by weight of water to obtain cement slurry A2. The density of the cement slurry A3 measured by the specific gravity method is 1.60g / cm 3 .

[0080] (2) Preparation of coal underground gasifier

[0081] An underground coal gasifier was prepared according to the method of Example 1, except tha...

Embodiment 3

[0083] This example is used to illustrate the cement composition of the present invention and its application.

[0084] (1) Preparation of cement slurry

[0085] The particle diameter of 22 parts by weight is about 160 mesh quartz sand (SiO 2 Content is about 96% by weight), the particle diameter of 18 parts by weight is about 220 mesh quartz sand (SiO 2 content is about 98% by weight), 15 parts by weight of expanded perlite (purchased from Pingqiao Xinyuan Thermal Insulation Material Factory) and 2 parts by weight of water glass are mixed. Then, the obtained mixture was mixed with 100 parts by weight of G-grade oil well cement (purchased from Shandong Huayin Special Cement Co., Ltd.) and 50 parts by weight of water to obtain cement slurry A3. The density of the cement slurry A3 measured by the specific gravity method is 1.80g / cm 3 .

[0086] (2) Preparation of coal underground gasifier

[0087] The underground coal gasification furnace was prepared according to the metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com