Underground coal gasification system and producing process

A technology for underground gasification and coal, which is applied in coal gasification, underground mining, construction, etc., can solve the problems of difficulty in stably controlling gasification efficiency and low gasification efficiency in the process of underground coal gasification, so as to eliminate surface collapse, improve quality and production. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

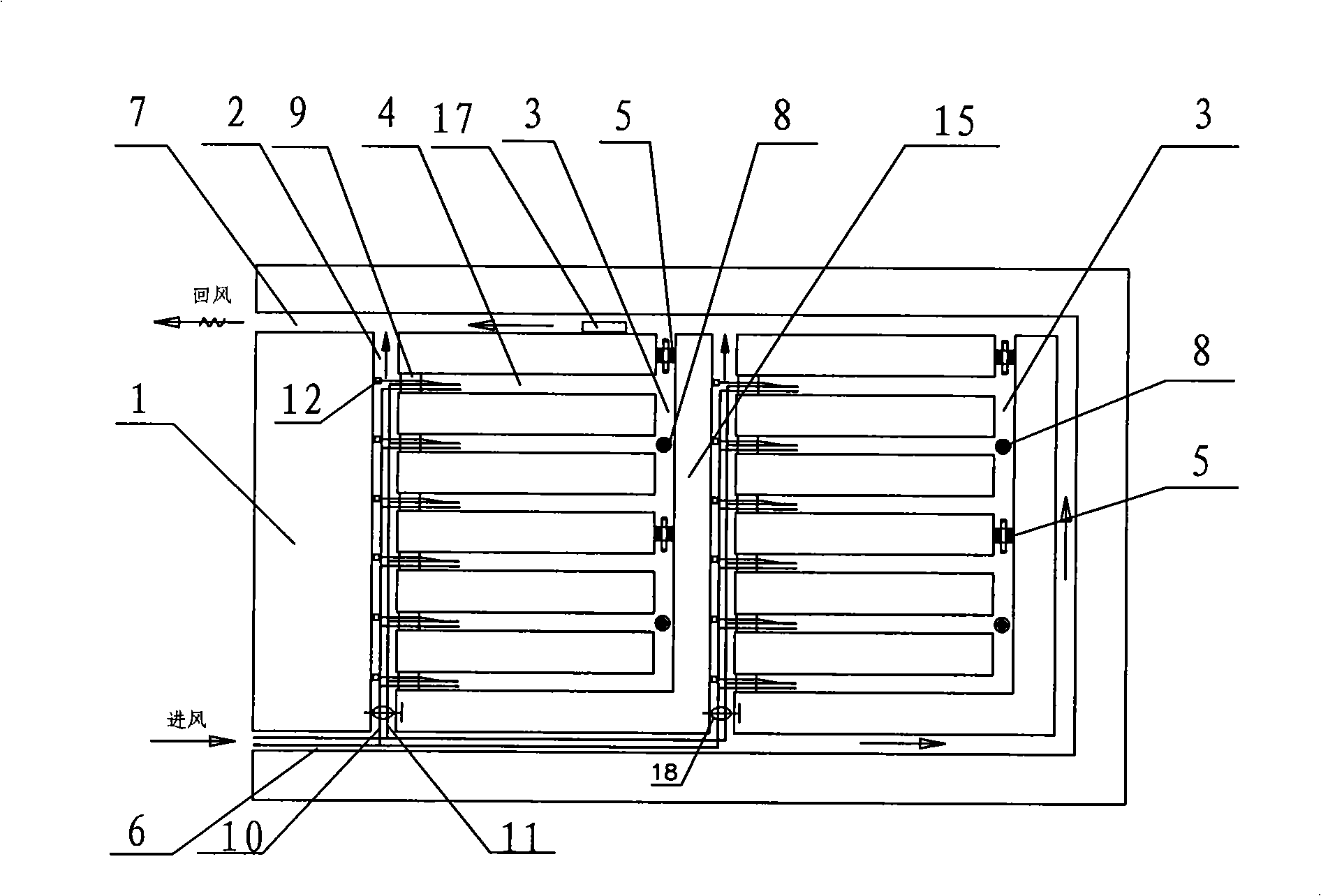

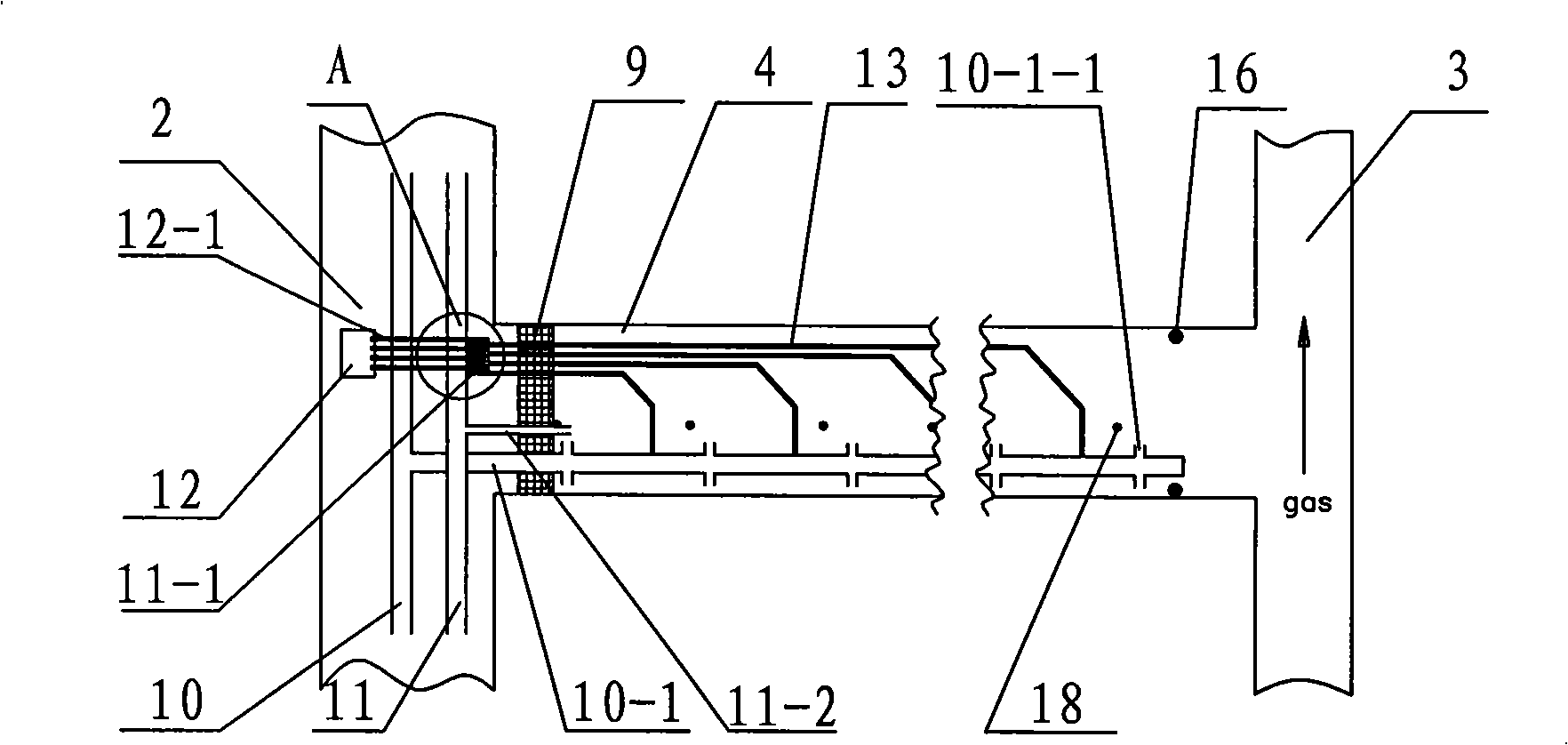

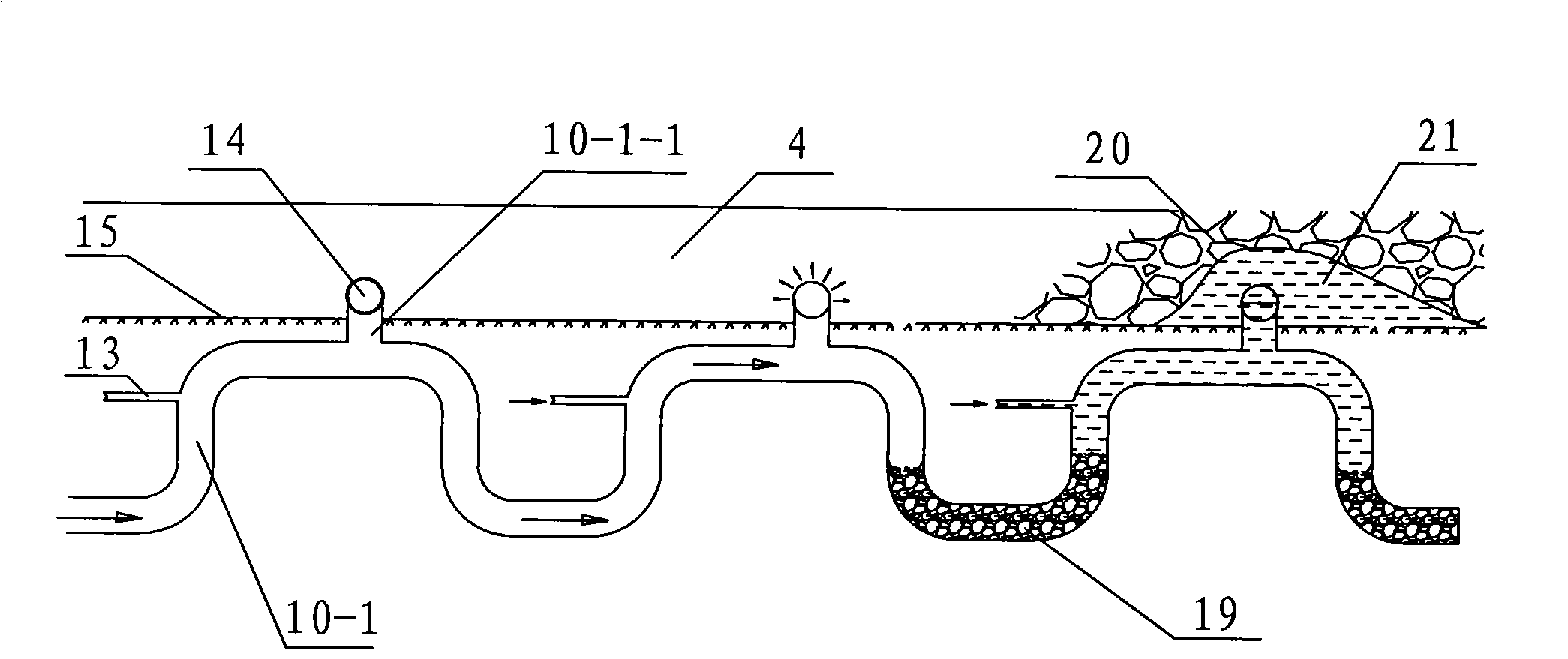

[0027] An embodiment of an underground coal gasifier, see figure 1 , 2 , 3, 4 and 5, figure 1 It is a schematic diagram of an underground gasification production system viewed from above; the underground gasification furnace includes a ventilation tunnel 2 and a gas transportation tunnel 3 arranged in a coal seam 1, and the ventilation tunnel 2 and the gas transportation tunnel 3 are on a plane and parallel to each other , several gasification channels 4 are set in the coal seam 1, the gasification channels are parallel to each other, and the two ends are respectively connected with the ventilation roadway and the gas transportation roadway, and the drainage airtight wall 5 is arranged in the gas transportation roadway; The ends are respectively connected to the air inlet roadway 6 and the air return roadway 7 of the mine system (one end of the gas transmission roadway is first communicated with the air return roadway 7 and then isolated by the drainage airtight wall 5), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com