Special strip type filling mining method

A backfill mining method and strip-type technology, which is applied in special mining, backfill, surface mining, etc., can solve the problems of gas escape and insufficient underground gangue, save time, reduce engineering disturbance, and achieve excellent results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

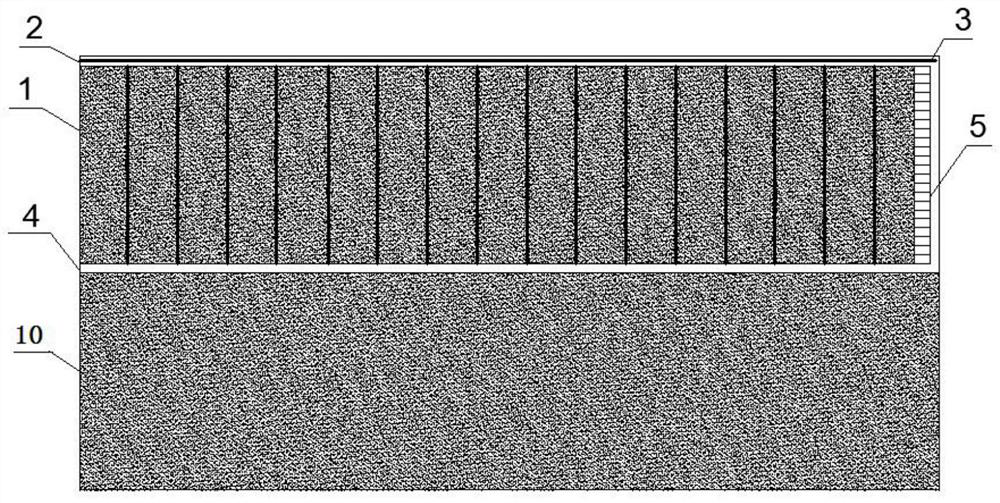

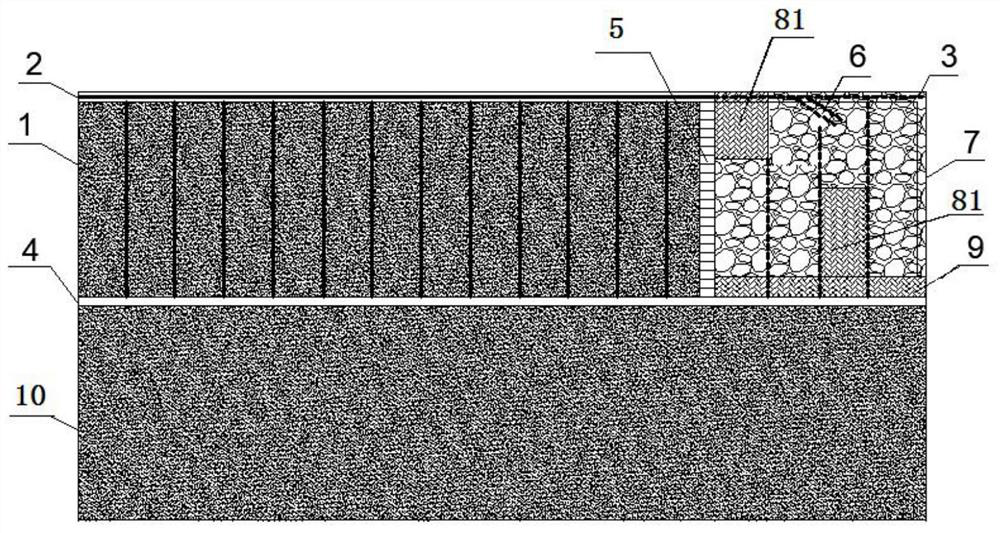

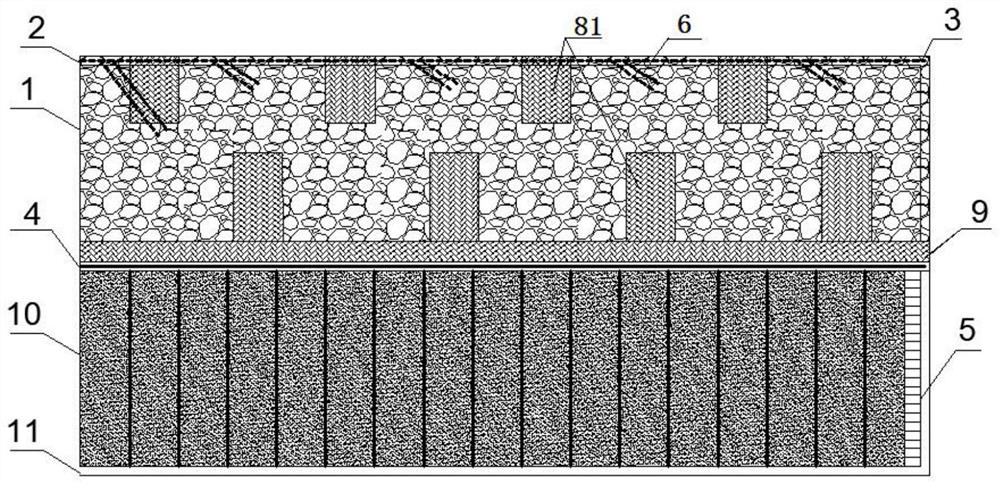

[0029] refer to Figure 1 to Figure 6 , this embodiment provides a special strip filling mining method, as follows:

[0030] Taking the first section 1, the second section 10, the third section 12 to the fourth section 13 as examples, firstly, each section is divided into a plurality of partial filling areas 8 and collapsed areas 7 in a strip shape, and the local filling Zones 8 are distributed at equal intervals along the mining direction. Between two adjacent partial filling zones 8 is a caving zone 7. Starting from section 1, along the mining direction, two partial filling zones 8 and two caving zones Zone 7 is taken as a group, i.e. a mining cycle, to be mined zone by zone, and partial backfill support is carried out at the same time as partial filling zone 8 is exploited, so that the partial filling zone 8 after mining has local support 81, and the adjacent partial filling zone The local supports 81 in 8 are arranged in a staggered manner. While mining, the construction ...

Embodiment 2

[0035] refer to Figure 1 to Figure 6 , taking the mining of section 1 as an example, the specific steps are as follows:

[0036] 1) A section 1 is divided into a plurality of partial filling areas 8 and collapsed areas 7 in a strip shape. Assuming that the first mining area is the caving area 7, during mining, the coal cutter pushes and moves the frame every time a knife is cut, and after the filling hydraulic support 5 moves a step, it supports the side of the roadway in the moving step. The upper and lower parts of the filling area are equipped with baffles, and the filling area is filled with coal gangue transported by the filling hydraulic support 5. After the front side is filled with one knife, the next coal cutting and filling process can be carried out until the strip mining is completed and the roadside support 9 The filling area is filled;

[0037] 2) The second mining area is the partial filling area 8. When mining the local filling area 8, the local support 81 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com