Axial oscillating tool for drill string

An oscillating tool and axial technology, applied in vibration drilling, liquid/gas jet drilling, etc., can solve the problems of limited drilling footage in the horizontal section, poor ability to transmit drilling pressure, and small size of coiled tubing, etc., to improve mechanical drilling. High speed, strong axial vibration ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

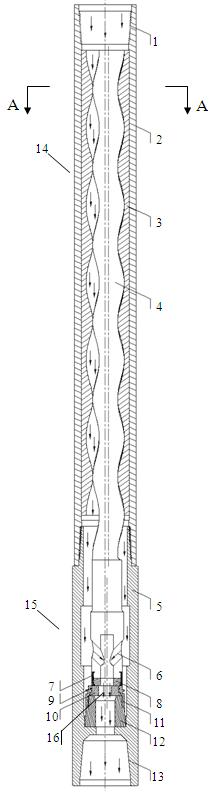

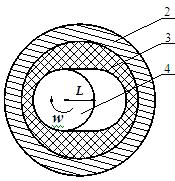

[0012] Such as figure 1 , figure 2 with image 3 As shown, a drill string axial oscillation tool is composed of two parts: a stator-rotor unit 14 and a valve unit 15, the stator-rotor unit 14 is composed of a stator housing 2, a stator rubber 3 and a rotor 4; the valve unit 15 It consists of a valve housing 5, a valve body 8, a valve body nut 7, a valve seat 10, a valve seat nut 11, a valve seat support body 12, and a valve seat seal 9. It is characterized in that: the inner wall of the stator housing 2 is vulcanized with stator rubber 3. The stator rubber 3 and the rotor 4 form a sealed cavity, and the lower end of the rotor 4 is provided with a flow channel oblique hole 6, and the valve body 8 is fixed to the lower end of the rotor 4 through the valve body nut 7; and the valve seat 10 is connected to the valve seat through the valve seat nut 11 On the support body 12, a valve seat seal 9 is installed between the valve seat 10 and the valve seat nut 11, and the valve seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com