Well drilling type oil gas preparing system through gasification and dry distillation of oil shale at normal position and technical method thereof

A process method and technology for shale oil and gas, which are applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of small retorting range, long heating cycle, and large environmental pollution, and avoid accumulation and processing. The effect of shortened production process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

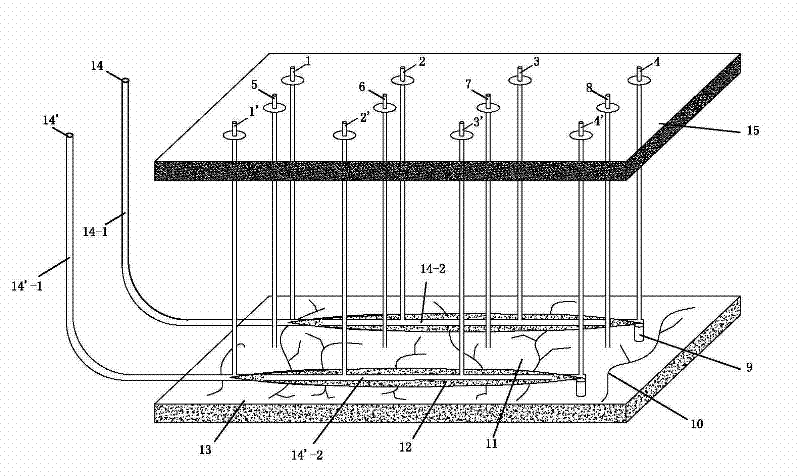

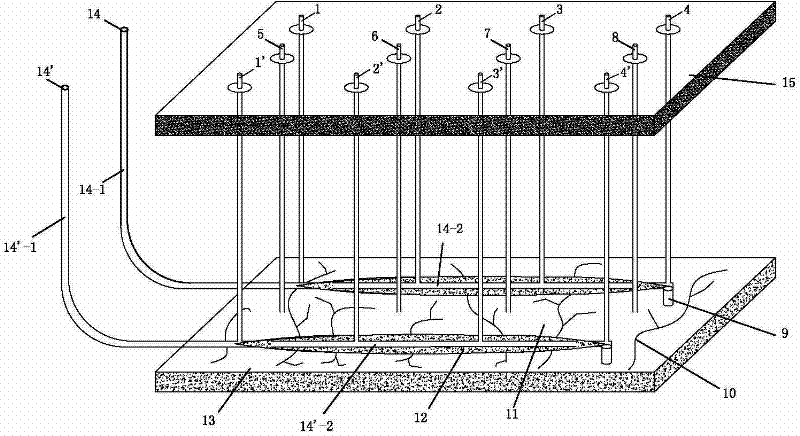

[0023] In this example, oil shale itself can be combusted and gasified to release heat and generate high-temperature gas, and a gasification area and a retort panel area are constructed in the in-situ oil shale layer, and the oil shale layer is retorted by heat conduction, convection and self-heating to produce Shale oil and combustible gas.

[0024] Drilling type oil shale in-situ gasification and retort oil and gas production system, an in-situ gasification and retort panel area is established in the oil shale layer, wherein the smallest unit of the in-situ gasification and retort panel area includes gasification controlled by at least two directional wells The horizontal section of the directional well is in the lower part of the oil shale layer, an ignition well is provided from the end of the horizontal section of the directional well to the ground, and multiple auxiliary gasification wells are arranged from the horizontal section of the directional well to the ground, and...

Embodiment 2

[0035] This embodiment consists of six minimum units described in Embodiment 1.

[0036] In this embodiment, the drilling type oil shale in-situ gasification and carbonization oil and gas production system consists of 7 gasification zones and 6 carbonization zones arranged in a staggered manner. There are 7 directional wells, 7 ignition wells, 21 auxiliary gasification wells, 24 Two oil and gas collection wells, the arrangement mode is the same as embodiment 1.

[0037] The width of the gasification zone controlled by the directional well in the smallest unit is 30m, the inner diameter of the directional well is 150mm, and the length of the horizontal section is 300m. Three auxiliary gasification wells are arranged between the ignition wells; the diameter of the ignition well is 350mm, and the bottom of the hole is 600mm in radius and 2.5m in height; the diameter of the auxiliary gasification well is 250mm, and the spacing is 70m. The bottom of the rock formation is 2m. The ...

Embodiment 3

[0040] For the embodiment of the drilling type oil shale in-situ gasification and carbonization system, please refer to the attached figure 1 In this embodiment, oil shale itself can be combusted and gasified to release heat and generate high-temperature gas. An in-situ gasification and retort panel area is established in the oil shale layer, and a gasification area and a retort area are established alternately in the oil shale layer. The convective self-heating method retorts oil shale formations to produce shale oil and combustible gas. Multiple gasification zones and retort zones are arranged staggeredly to form a drilling-type oil shale in-situ gasification and retort system for oil and gas production. The gasification area is combusted and gasified, and the heat generated while producing shale gas heats the retort area, which produces shale oil and gas, realizing in-situ self-heating retort. Control the oil shale combustion range in the gasification area, and form a comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com