Volume fracturing directional well arranging method for ultra-low permeability dense reservoir

A volume fracturing and tight oil reservoir technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of difficult to obtain development benefits, poor production stability, easy water seepage, etc., to improve single well Yield and development benefits, avoiding cracked water flooding, and improving the effect of initial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in further detail below in conjunction with accompanying drawing:

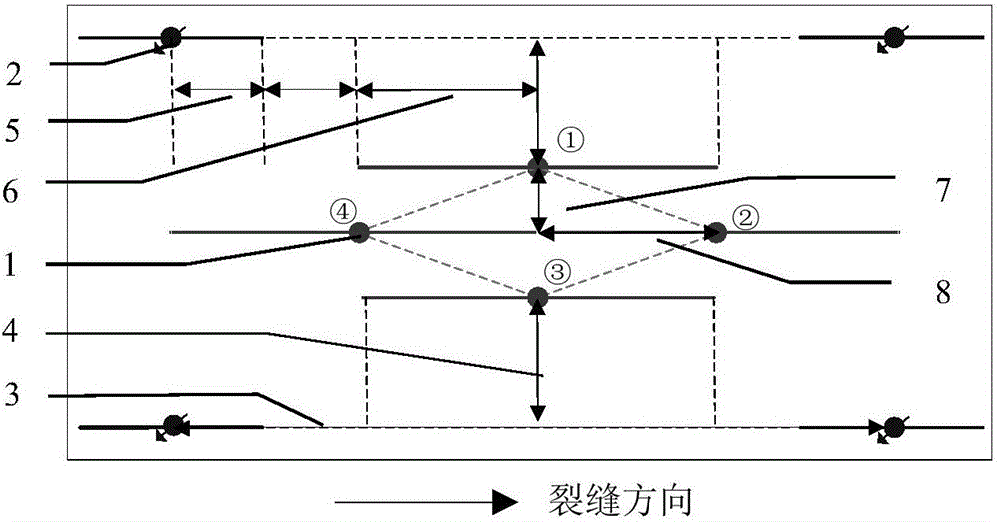

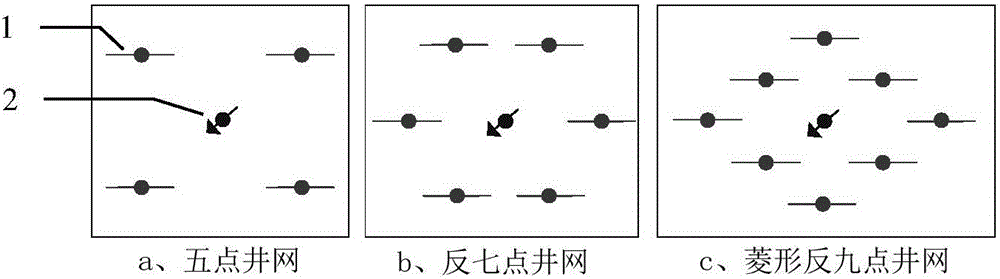

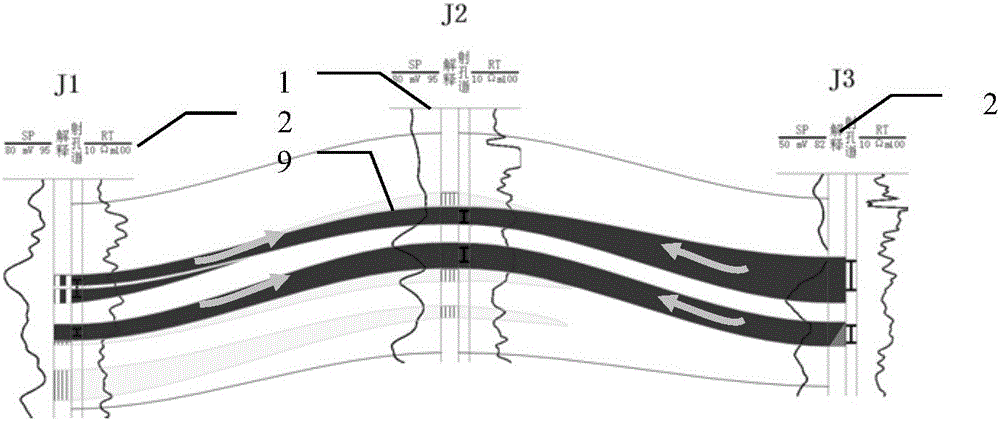

[0051] see Figure 1-Figure 13 , the present invention ultra-low permeability tight reservoir volume fracturing directional well layout method, comprising the following steps:

[0052] 1) First, carry out comprehensive geological research, optimize the deployment area of directional well pattern, carry out classification and evaluation of reservoirs, and determine the main contribution layers.

[0053](1) On the plane, firstly, the favorable sedimentary facies belts are determined through the study of sedimentary microfacies, diagenetic facies, and the main controlling factors of high yield and enrichment, and then comprehensive geological and reservoir engineering methods are used to analyze the characteristics of reservoir physical properties and pore throat structure. The four parameters of dynamic fluid saturation, pore throat radius and threshold pressure gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com