Coal and rock directional well sand fracturing physical simulation method

A technology of sand fracturing and physical simulation, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve problems such as inaccurate simulation results, achieve high accuracy, reduce errors, and fully expand fractures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

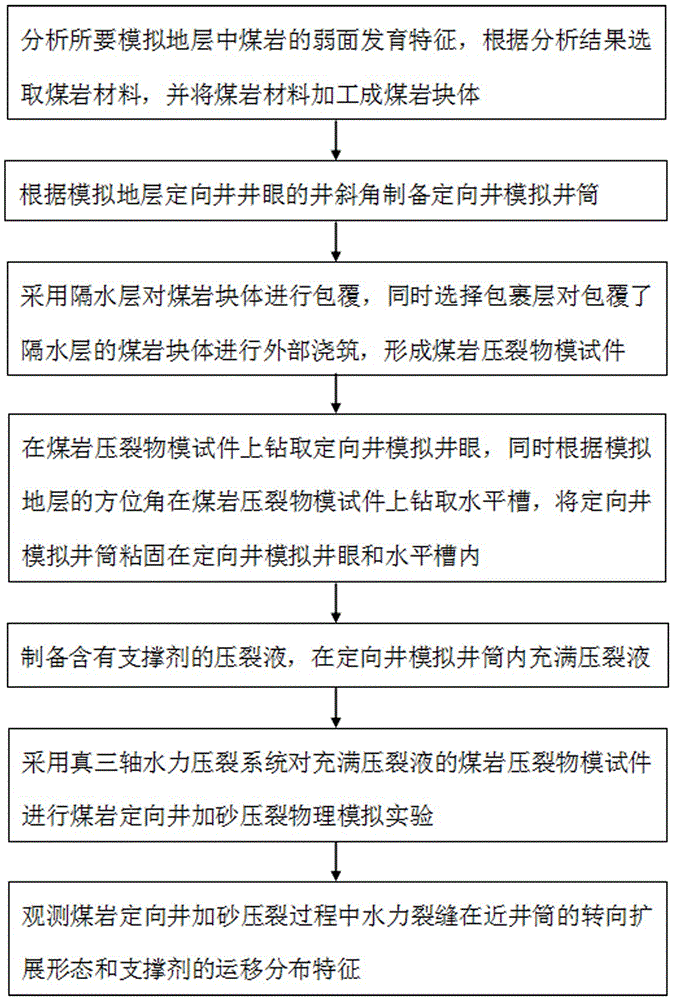

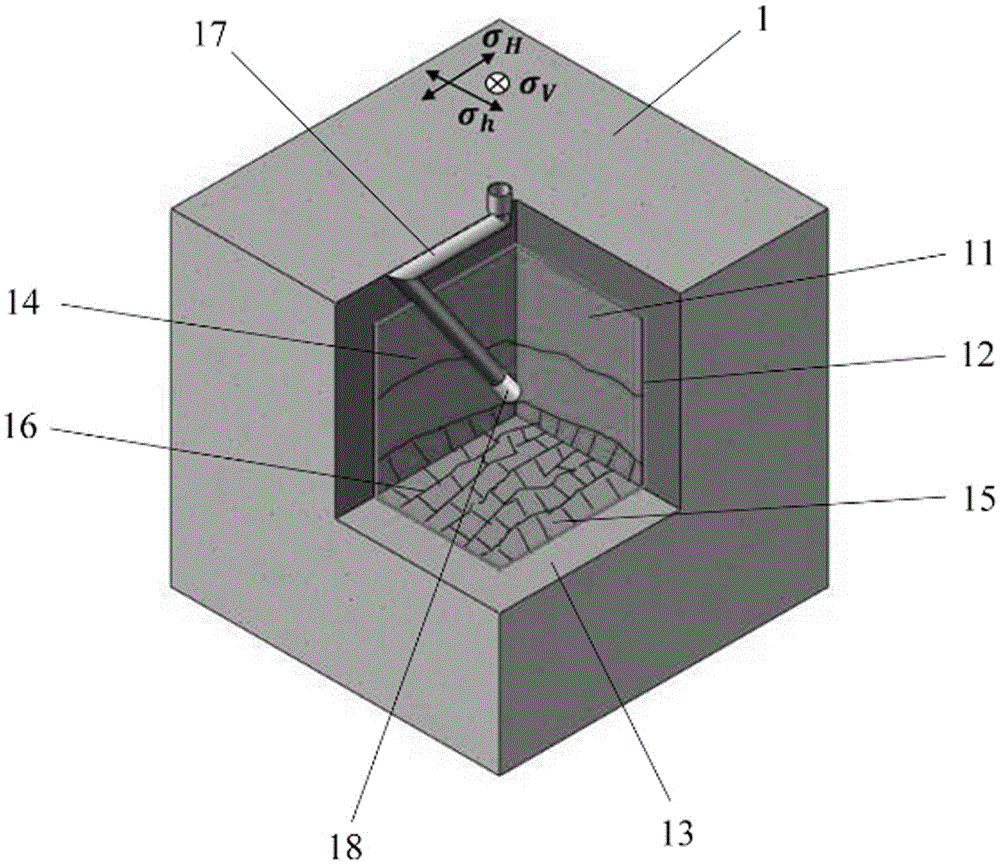

[0056] Such as figure 1 Shown, according to an embodiment of the physical simulation method of the coal rock directional well sanding fracturing of the present invention, it comprises the following steps in sequence:

[0057] Step 1: Analyze the weak plane development characteristics of the coal rock in the stratum to be simulated, select coal rock materials according to the analysis results, and process the coal rock materials into coal rock blocks;

[0058] Step 2: Prepare a directional well simulation wellbore according to the inclination angle of the directional well borehole in the simulated formation;

[0059] Step 3: Use the water-resisting layer to cover the coal-rock block, and at the same time select the wrapping layer to pour the coal-rock block covered with the water-resisting layer externally to form a coal-rock fracturing model test piece;

[0060] Step 4: After the cladding layer is consolidated, drill a directional well simulated borehole on the coal-rock frac...

Embodiment 2

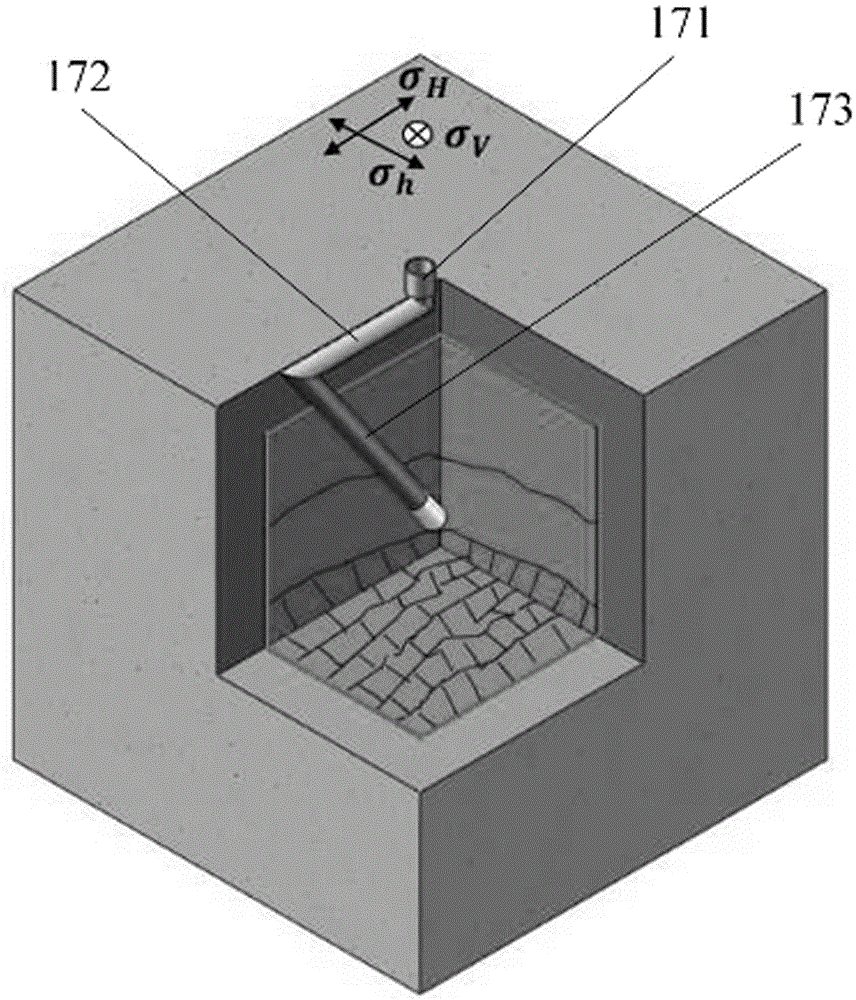

[0077] According to another embodiment of the physical simulation method of sanding and fracturing in coal rock directional wells of the present invention, its process flow, principle and beneficial effects are all the same as those in Embodiment 1, the difference is: the outer surface of the directional well simulated wellbore The diameter is 16mm, the inner diameter is 10mm; the length of the simulated shaft of the auxiliary vertical section is 15mm; the thickness of the cladding layer is 70mm, and the side length of the finally obtained coal rock fracturing model specimen is 440mm; The diameter of the simulated wellbore is 19 mm, and an open hole section with a length of 50 mm is reserved at the lower end. The center of the open hole section is located at the center of the coal rock fracturing model test piece; the length of the horizontal groove is 50 mm and the depth is 19 mm. ; Use AB silica gel to cement the simulated wellbore of the directional well in the simulated bor...

Embodiment 3

[0079] According to another embodiment of the physical simulation method of sanding and fracturing in coal rock directional wells of the present invention, its process flow, principle and beneficial effects are all the same as those in Embodiment 1, the difference is: the outer surface of the directional well simulated wellbore diameter is 17mm, internal diameter is 11mm; the length of the simulated wellbore of the described auxiliary vertical section is 20mm; the thickness of the cladding layer is 60mm, and the side length of the finally obtained coal rock fracturing model specimen is 420mm; The diameter of the simulated wellbore is 20 mm, and an open hole section with a length of 40 mm is reserved at the lower end. The center of the open hole section is located at the center of the coal rock fracturing model test piece; the length of the horizontal groove is 50 mm and the depth is 20 mm. ; Use AB silica gel to cement the simulated wellbore of the directional well in the simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com