Self-plugging removal carbonate reservoir drill-in fluid

A self-plugging technology for carbonate reservoirs, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve the problems of strong heterogeneity and uncertainty of fracture opening in carbonate reservoirs , Reservoir permeability reduction and other issues, to achieve excellent leakage prevention and plugging ability while drilling, excellent reservoir protection performance, good filtration loss and wall building effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

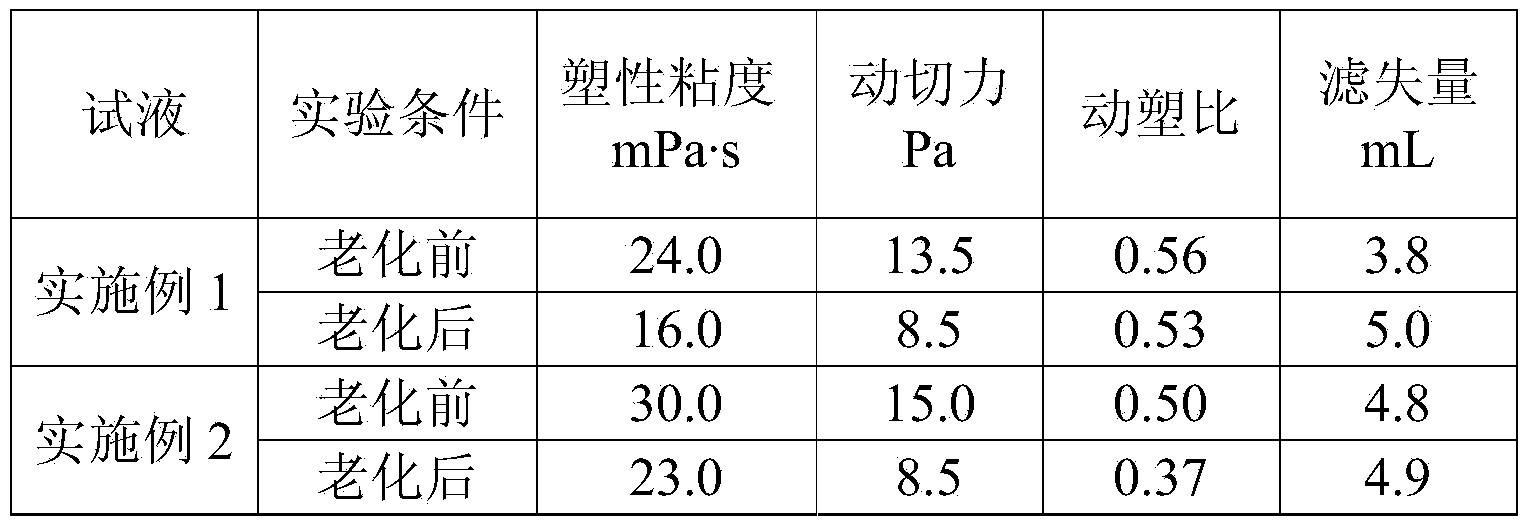

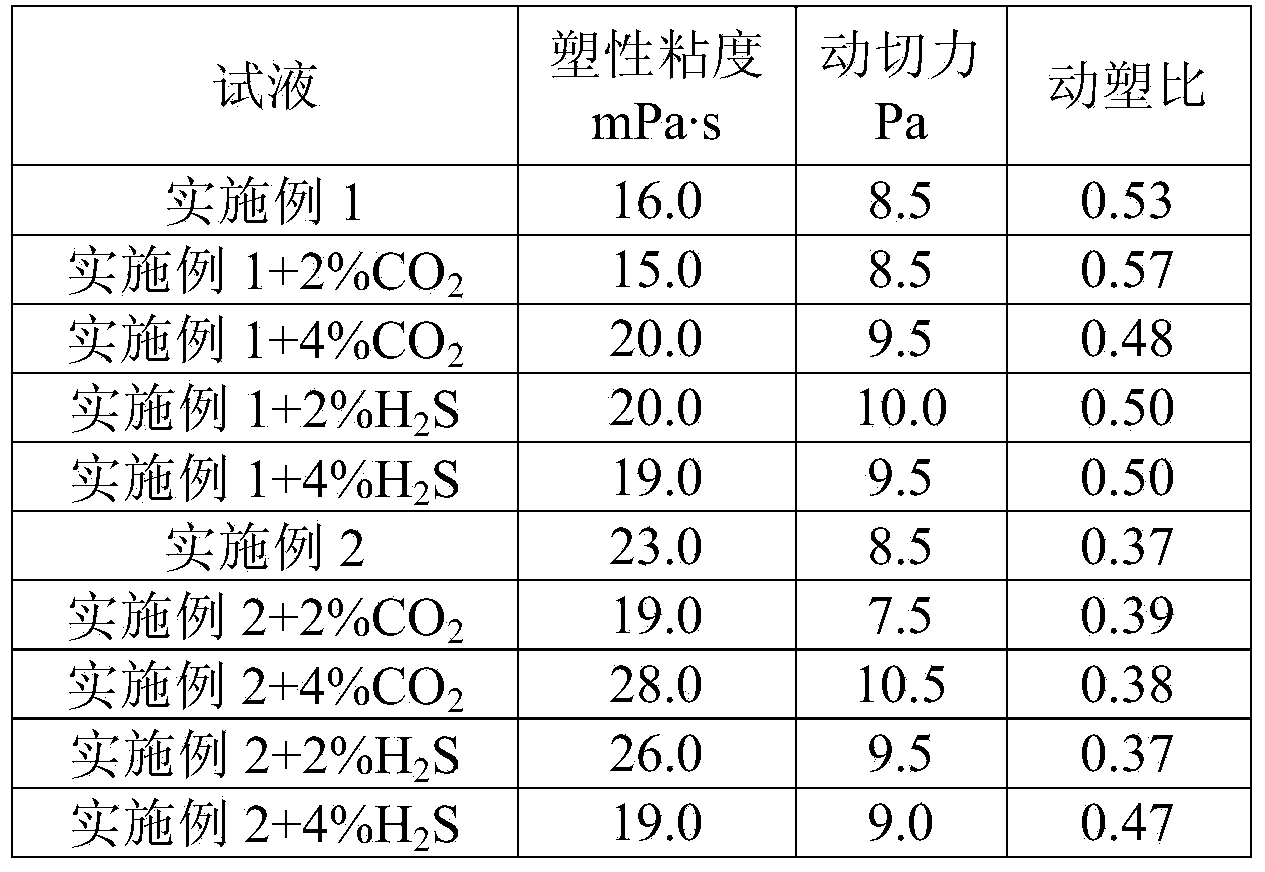

[0064] Embodiment 1, self-plugging carbonate reservoir drilling fluid

[0065] The composition of the self-plugging carbonate reservoir drilling fluid in this embodiment is as follows (all parts by mass):

[0066] 100 parts of water, 4 parts of cationic starch FLOCAT, 0.3 parts of low-viscosity polyanionic cellulose PAC-LV, 0.35 parts of high-viscosity polyanionic cellulose PAC-HV, 0.3 parts of potassium chloride, 0.2 parts of sodium hydroxide, 0.2 parts of sodium carbonate 9 parts of composite self-blocking temporary plugging agent, 0.1 part of cetyltrimethylammonium chloride, and 25 parts of sodium formate.

[0067] The composite self-blocking temporary plugging agent used in this example is a mixture of oil-soluble resin temporary plugging agent HS-140 and calcium carbonate, the mass ratio is 1:3, and the calcium carbonate has three particle sizes, each of which is 600 mesh , 800 mesh and 1000 mesh.

[0068] The drilling fluid density of the present embodiment is 1.15g / cm...

Embodiment 2

[0069] Embodiment 2, self-plugging carbonate reservoir drilling fluid

[0070] The composition of the self-plugging carbonate reservoir drilling fluid in this embodiment is as follows (all parts by mass):

[0071] 100 parts of water, 3.5 parts of carboxymethyl starch CMS, 0.6 parts of low viscosity carboxymethyl cellulose CMC-LV, 0.35 parts of xanthan gum, 0.3 parts of potassium chloride, 0.2 parts of sodium hydroxide, 0.2 parts of sodium carbonate, 14 parts of self-blocking temporary plugging agent, 100.1 parts of alkylphenol polyoxyethylene ether OP-100.1 parts, lubricant SD-5051 parts, 24 parts of 600 mesh calcium carbonate weighting agent.

[0072] The self-blocking temporary plugging agent used in this example is a mixture of oil-soluble asphalt temporary plugging agent BC-6 and calcium carbonate, the mass ratio is 1:4, and the calcium carbonate has two particle sizes, 800 mesh and 1000 mesh respectively. head.

[0073] The drilling fluid density of the present embodime...

Embodiment 3

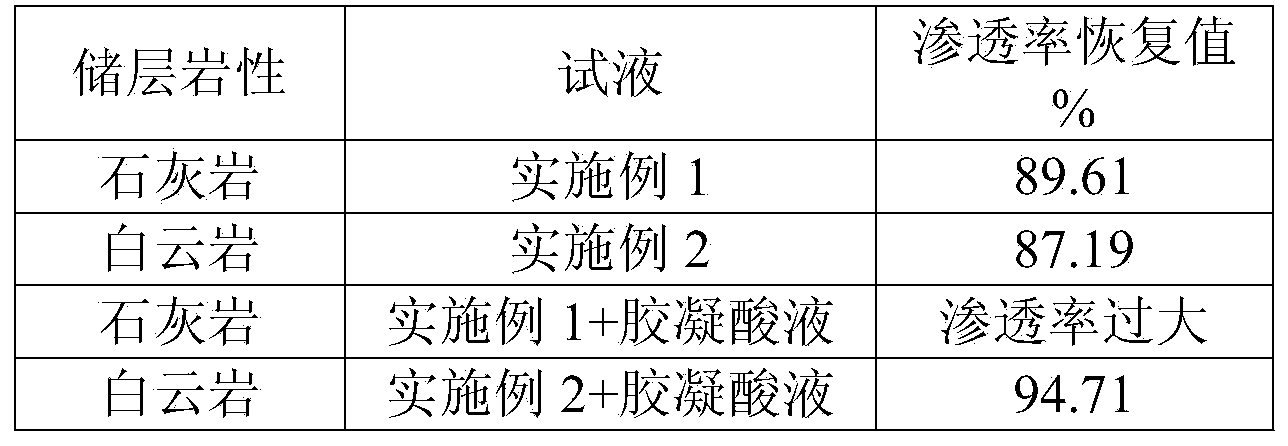

[0090] Embodiment 3, self-plugging carbonate reservoir drilling fluid

[0091] The composition of the self-plugging carbonate reservoir drilling fluid in this embodiment is as follows (all parts by mass):

[0092] Self-unplugging carbonate reservoir drilling fluid prepared in Example 1 (100 parts of water), 3.5 parts of acid-soluble fiber XHD, 32 parts of acid-soluble fiber DL-932, mica flakes (particle size 1-3mm) 1.5 parts, 2 parts fruit shell (particle size 2mm), 4 parts superfine calcium carbonate (200-400 mesh).

[0093] The purpose of the self-removing plugging fluid for drilling carbonate rock reservoirs prepared in Example 3 is to improve the leakage prevention and plugging ability of the drilling fluid while drilling when drilling large-opening fractured reservoirs or when fractured leakage has occurred.

[0094] The effect of the self-unplugging carbonate reservoir drilling fluid prepared in Example 3 is tested below.

[0095] The plugging effects of the reservoir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com