Processing technology of u-shaped seamless stainless steel pipe and stainless steel pipe

A stainless steel pipe and processing technology, applied in the field of steel pipe processing, can solve problems such as unfavorable long-term use of elbows, poor surface roughness, nitriding risk, etc., to reduce the risk of surface scratches, excellent corrosion resistance, and improved corrosion resistance. The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

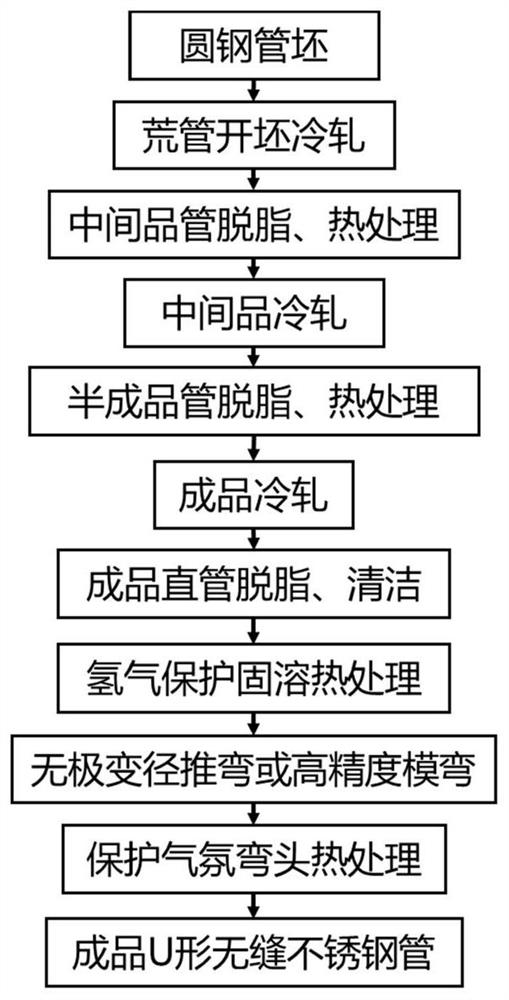

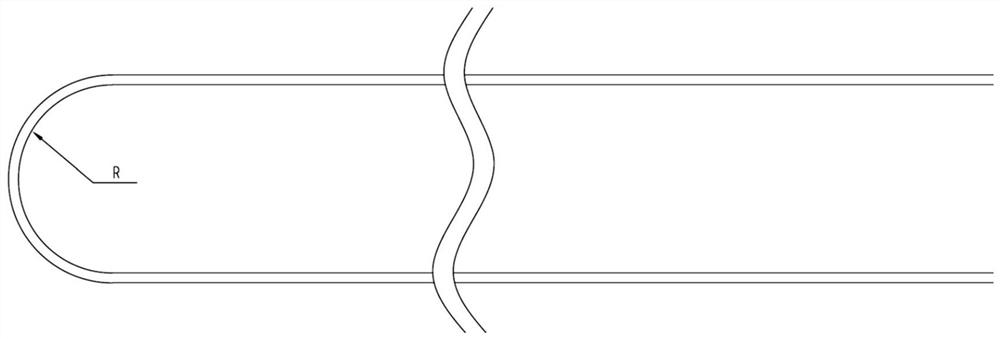

[0033] Such as figure 1 As shown, the wall thickness is 1.0±0.1mm, the outer diameter of the pipe is 16.0±0.08mm, the length after expansion is between 45m and 50m, the inner and outer surface roughness is ≤0.5μm, and there is no oxidation color and nitriding layer on the surface. U-shaped seamless stainless steel pipe with good corrosion resistance, bending radius R=550mm, and bending radius R tolerance ±0.5mm includes the following steps:

[0034] 1) Cross-rolling and hot piercing the round steel billet of Φ80 to make a blank pipe of Φ80×8mm;

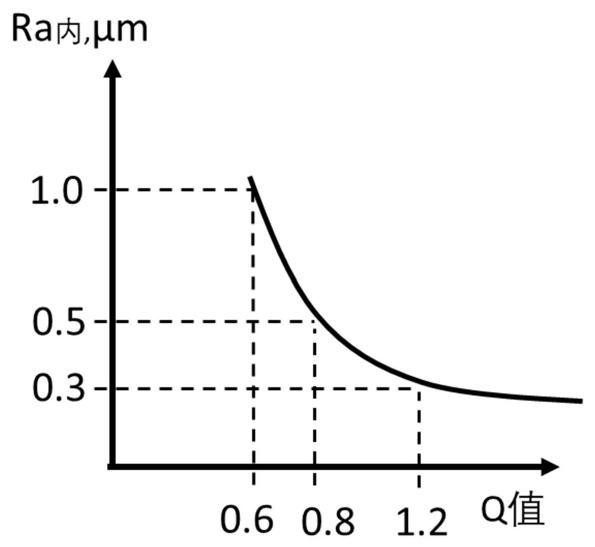

[0035]2) Use high-speed cold-rolling equipment combined with a medium-to-high deformation design of 40% to 80% to carry out billet cold-rolling processing, and process blank pipes to intermediate-quality pipes of Φ57×5.5mm. The deformation amount of this pass = 1-((rolling Outer diameter after rolling - wall thickness after rolling) × wall thickness after rolling) / ((outer diameter before rolling - wall thickness before rolling) × ...

Embodiment 2

[0045] Such as figure 1 As shown, the wall thickness is 1.0±0.1mm, the outer diameter of the pipe is 16.0±0.08mm, the length after expansion is between 45m and 50m, the inner and outer surface roughness is ≤0.5μm, and there is no oxidation color and nitriding layer on the surface. U-shaped seamless stainless steel pipe with good corrosion resistance, bending radius R=150mm, and bending radius R tolerance ±0.5mm includes the following steps:

[0046] Step 1) to step 8) are identical with embodiment one;

[0047] Step 9) adopt high-precision die bending technology for the finished straight pipe after heat treatment in step 8), and select nylon material as the bending pipe mold material. When designing the bending mold, the anti-deformation design is adopted. The cavity shape of the mold is no longer a regular circle, but a smaller outer diameter perpendicular to the plane direction of the U-shaped tube, and an outer diameter parallel to the plane direction of the U-shaped tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com