Multielement compound saltwater drilling fluid

A brine drilling fluid and multi-component compounding technology, applied in the direction of drilling composition, chemical instruments and methods, can solve problems such as wellbore instability, aggravated rock dissolution and hydration, poor wellbore stability, etc., to achieve resistance Slow formation pressure transmission, enhanced wellbore stability, and good plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

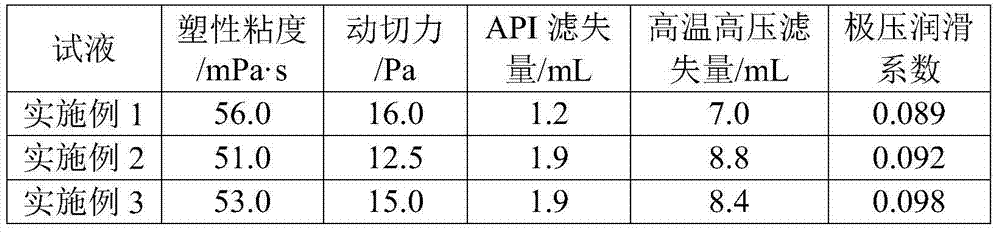

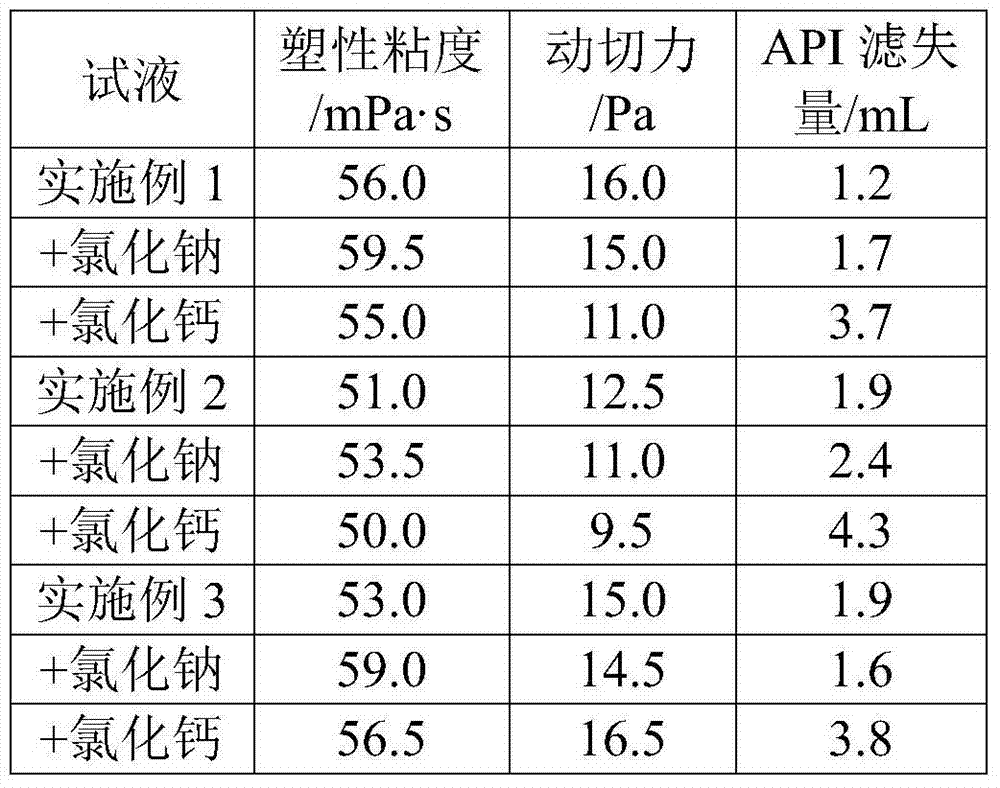

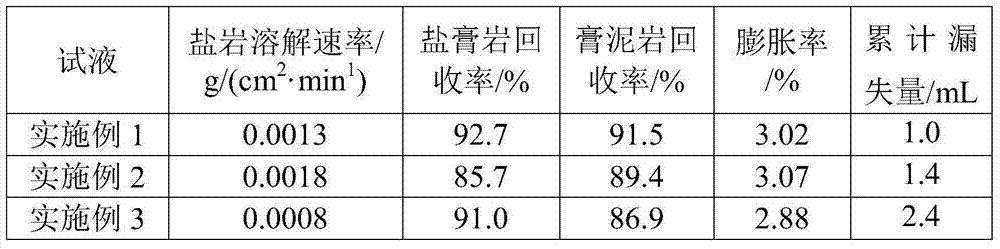

Embodiment 1

[0035] The multi-component compound salt undersaturated brine drilling fluid includes the following components in parts by mass:

[0036] 100 parts of water, 45 parts of multi-component compound salt, 3 parts of hypotonic film-forming agent PF-LPF, 5 parts of sulfonated phenolic resin SMP, 3.5 parts of cationic starch FLOCAT, 0.2 parts of sodium hydroxide, 0.15 parts of sodium carbonate, 7.5 parts of lubricant, 3 parts of sodium bentonite, 261 parts of viscosity reducer SF-240 parts of barite.

[0037] The multiple compound salt used in the present embodiment is the mixture of sodium chloride, potassium chloride, calcium chloride and sodium formate.

[0038] The lubricant used in this example is a mixture of graphite powder, white oil (5#) and RT-101.

[0039] The drilling fluid density of the present embodiment is 2.3g / cm 3 .

Embodiment 2

[0041] The multi-component compound salt undersaturated brine drilling fluid includes the following components in parts by mass:

[0042] 100 parts of water, 40 parts of multi-component compound salt, 8 parts of plugging agent, 3.5 parts of sulfonated lignite resin SPNH, 4 parts of carboxymethyl starch CMS, 0.1 part of polyanionic cellulose PAC-LV, 0.25 parts of sodium hydroxide, oxidized 0.1 parts of calcium, 6 parts of lubricant, 2 parts of mixed clay, SK-31 parts of viscosity reducer, 10.5 parts of salt crystallization inhibitor NTA-145 parts of barite.

[0043] The multi-element compound salt used in the present embodiment is the mixture of sodium chloride, sodium formate and cesium formate.

[0044] The plugging agent used in this example is a mixture of sulfonated asphalt resin DYFT-II and calcium carbonate with a mass ratio of 1:3, and the calcium carbonate has two particle sizes, 600 mesh and 800 mesh respectively.

[0045] The lubricant used in this example is a mixtur...

Embodiment 3

[0049] The multi-component compound salt saturated brine drilling fluid includes the following components in parts by mass:

[0050] 100 parts of water, 37 parts of multi-component compound salt, 12 parts of plugging agent, 4 parts of sulfonated phenolic resin SMP, 4.5 parts of sulfonated lignite resin SPNH, 0.15 parts of polyanionic cellulose PAC-LV, 9 parts of lubricant, sodium base 2 parts of bentonite, 0.25 parts of sodium hydroxide, 0.15 parts of sodium carbonate, 31 parts of viscosity reducer SK-31 parts, salt crystallization inhibitor NTA-10.5 parts, 200 parts of barite, 52 parts of trimanganese tetraoxide.

[0051] The multiple compound salt used in the present embodiment is the mixture of sodium chloride, potassium chloride and calcium chloride.

[0052] The plugging agent used in this example is a mixture of PF-LPF and calcium carbonate with a mass ratio of 1:3, and the calcium carbonate has two particle sizes, 600 mesh and 1000 mesh respectively.

[0053] The lubri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com