Fully mechanized top coal roof multiple segment control exploration method for deeply inclined coal seam

A fully mechanized roof caving and mining method technology, which is applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve problems such as support toppling, inability to guarantee the stability of the "roof-support-bottom" system of the working face, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

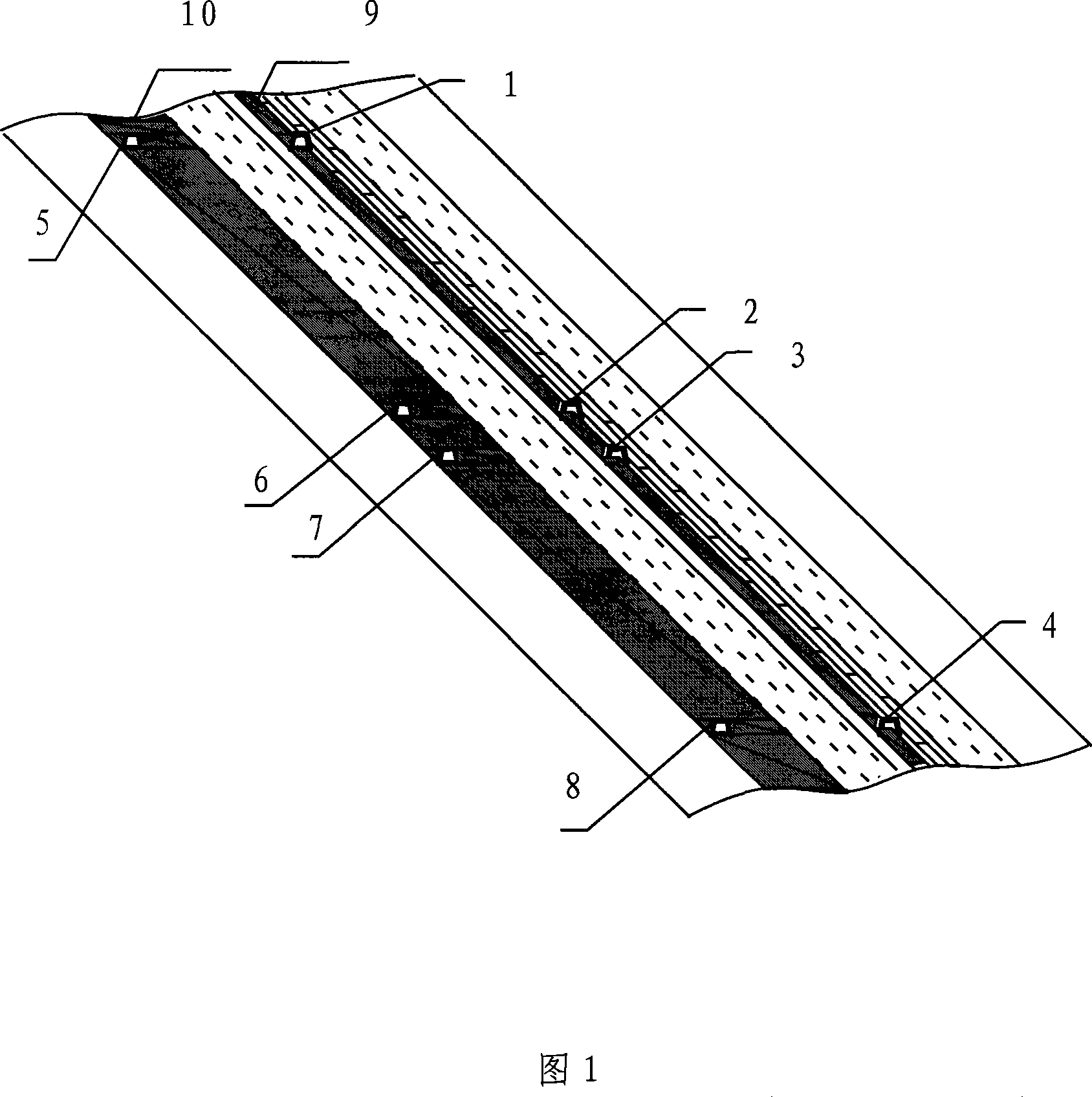

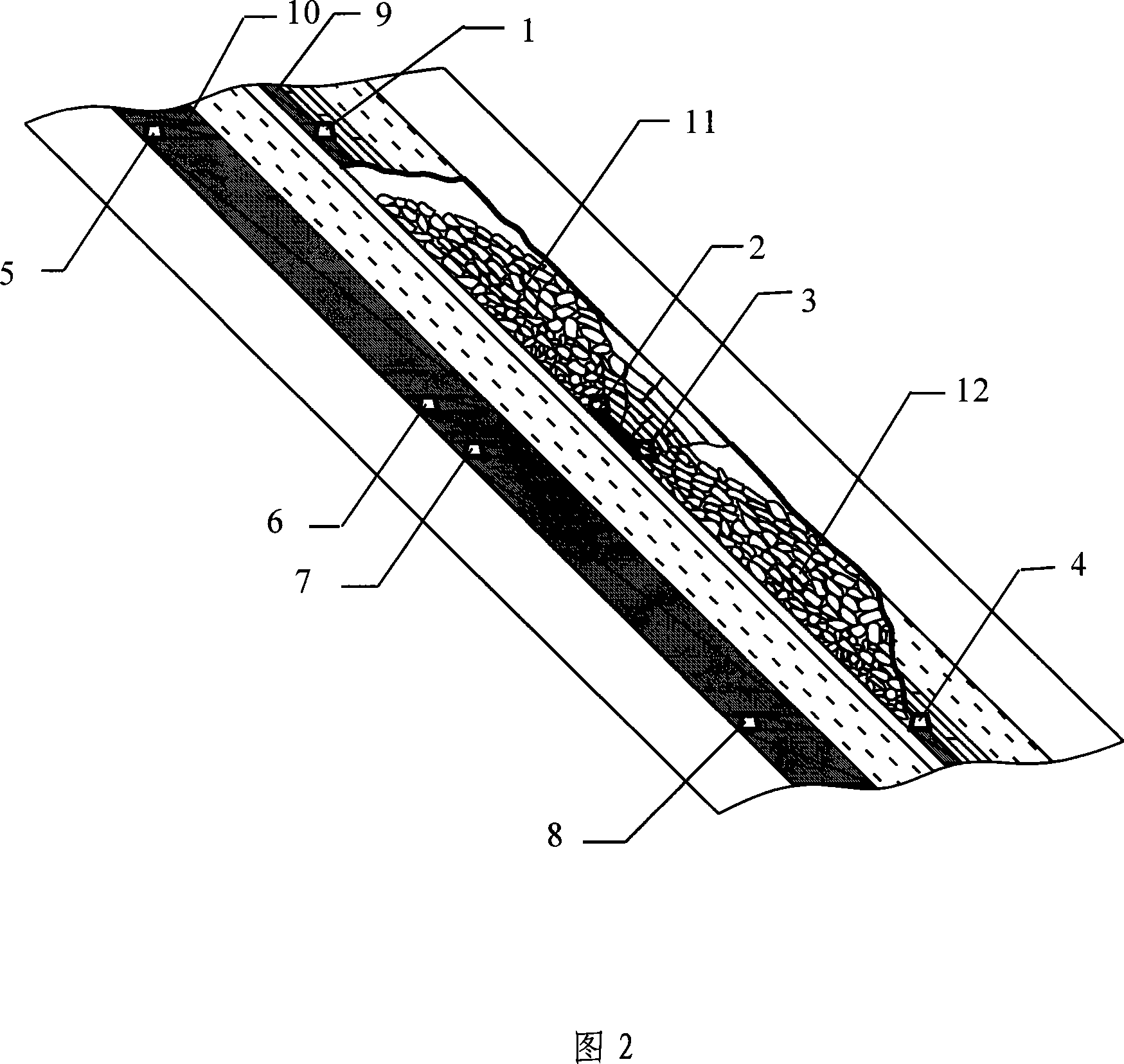

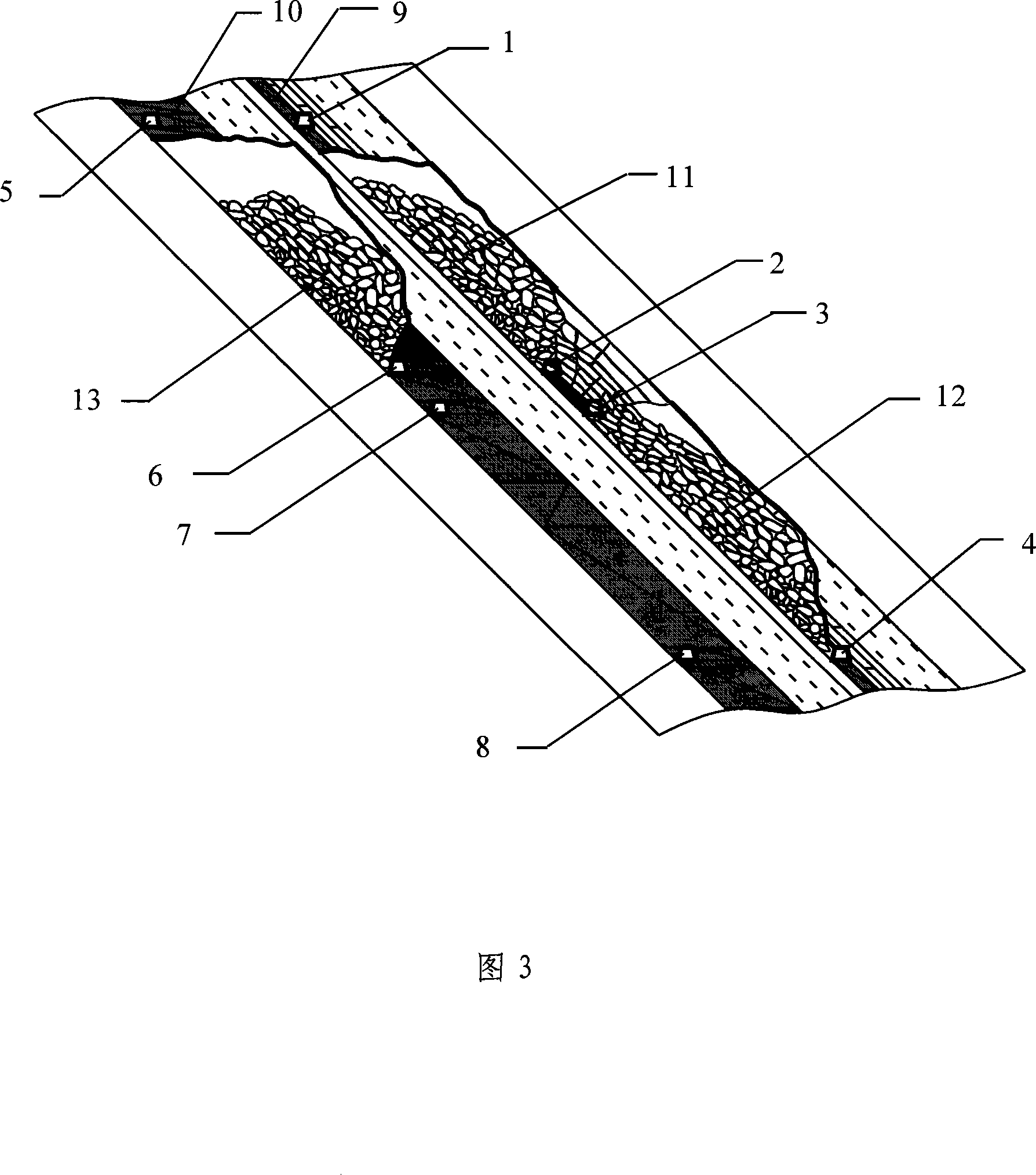

[0026] Taking the mining of a high-dip coal seam as an example, there are two coal seams in this stage: coal seam I9 and coal seam II10, and each coal seam is divided into two sections: coal seam I is formed by No. 1 parallel channel 1 and No. 2 parallel channel 2 The first section; the second section of coal seam I is formed by No. 3 parallel channel 3 and No. 4 parallel channel 4; the first section of coal seam II is formed by No. 5 parallel channel 5 and No. 6 parallel channel 6; the No. 7 parallel channel No. 7 and No. 8 along channel 8 form the second section of coal seam II.

[0027] The multi-section controlled mining method of top-coal caving roof in fully mechanized coal seam with large dip angle includes the following steps:

[0028] 1. Between the first section of coal seam I and the second section of coal seam I (between No. 2 parallel channel 2 and No. 3 parallel channel 3) there is a protective or isolated coal pillar; the first section of coal seam II and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com