Method for monitoring erosion deviation of blast furnace hearth

A blast furnace, deviation technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as large heat intensity gradient, distortion of measurement data, and difficult to achieve accuracy conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments. In the following embodiments, thermocouples are used as temperature sensors, referred to as thermocouples. Unless otherwise specified, thermocouples and thermocouples in the following detailed description can refer to any temperature sensor that meets the temperature detection requirements.

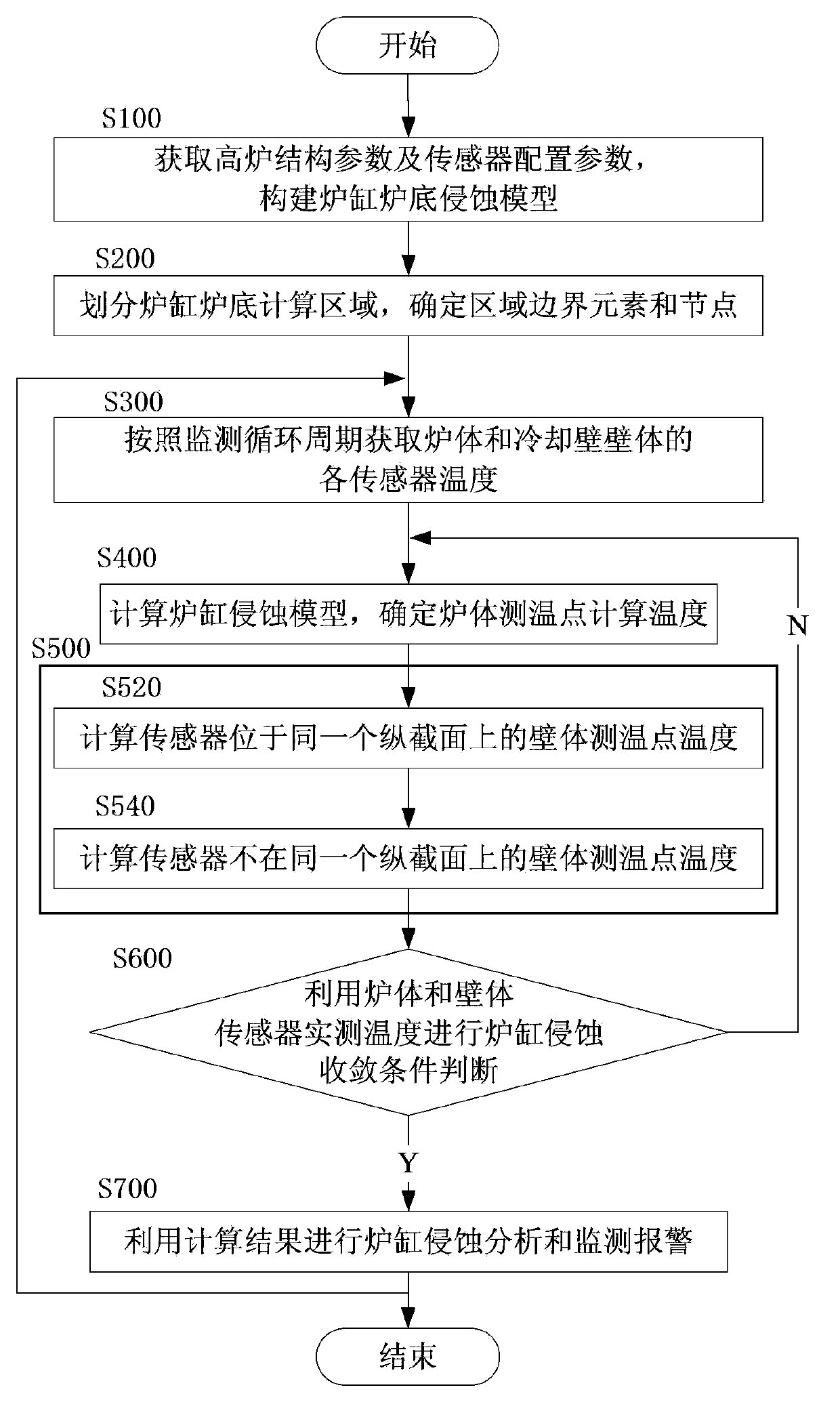

[0056] The control flow diagram of the blast furnace hearth erosion deviation monitoring method of the present invention is as follows figure 1 shown, including the following steps:

[0057] S100) Obtain the structural parameters of the blast furnace and the configuration parameters of each sensor, and construct a hearth bottom erosion model;

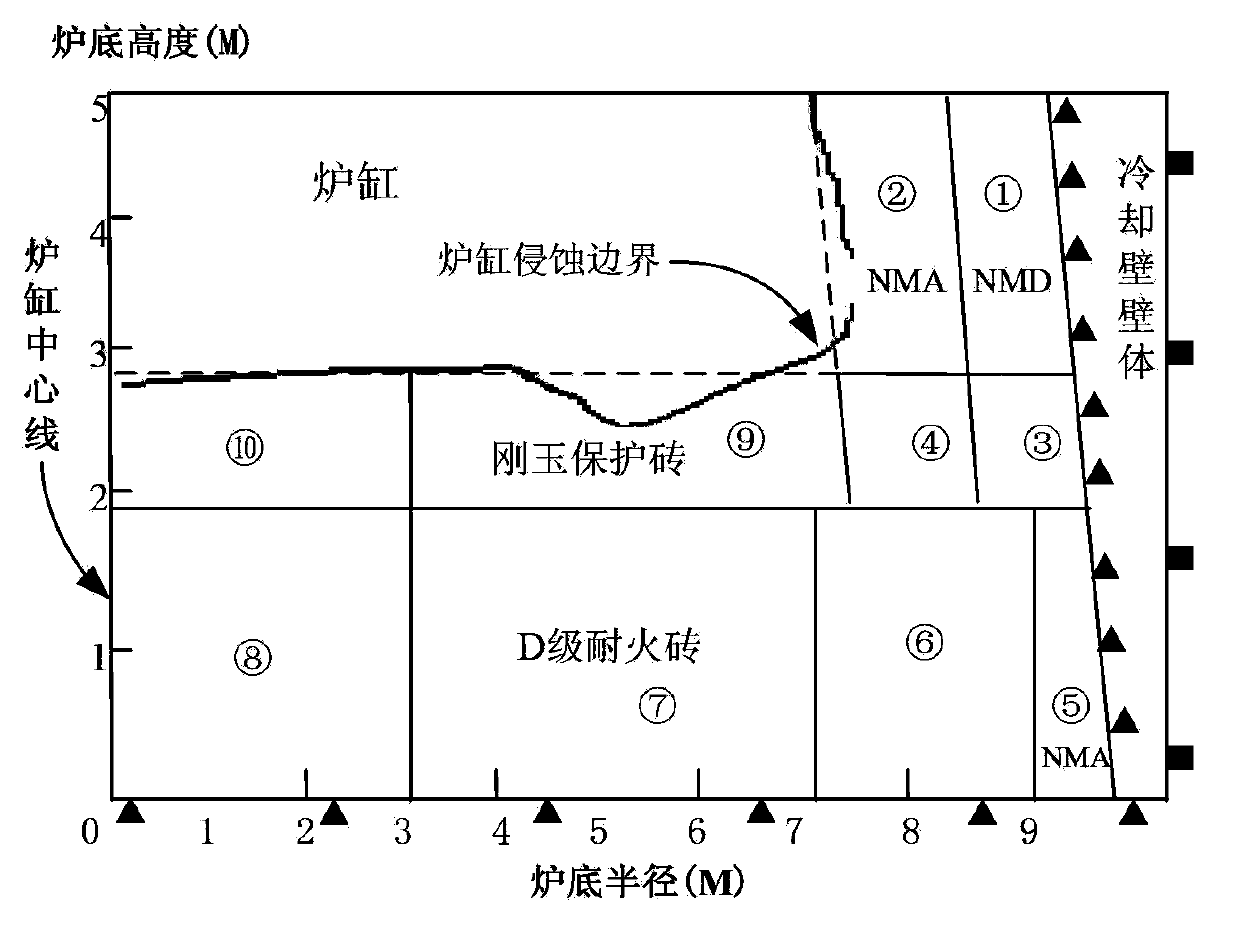

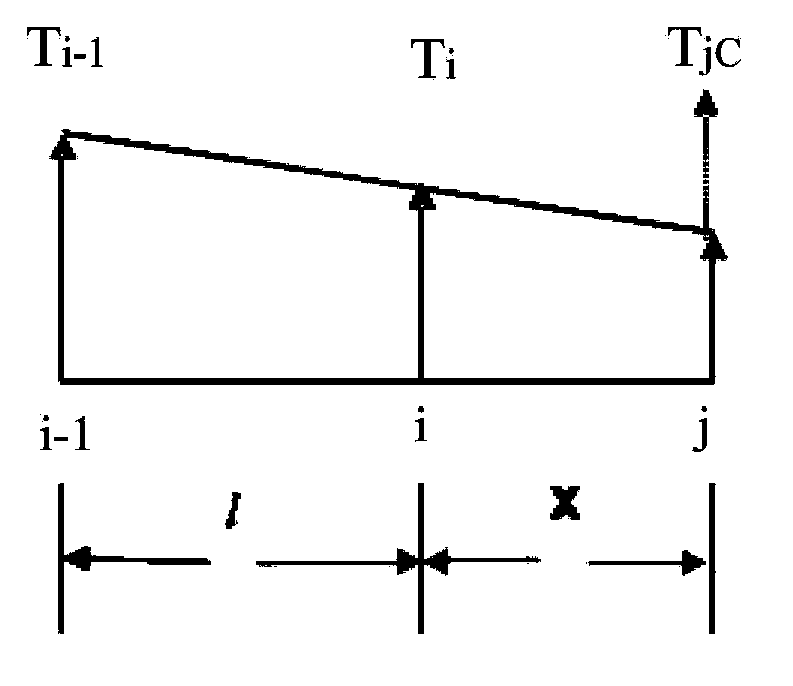

[0058] S200) According to the refractory material and shape of the furnace body, divide the calculation area of the hearth and bottom, and determine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com