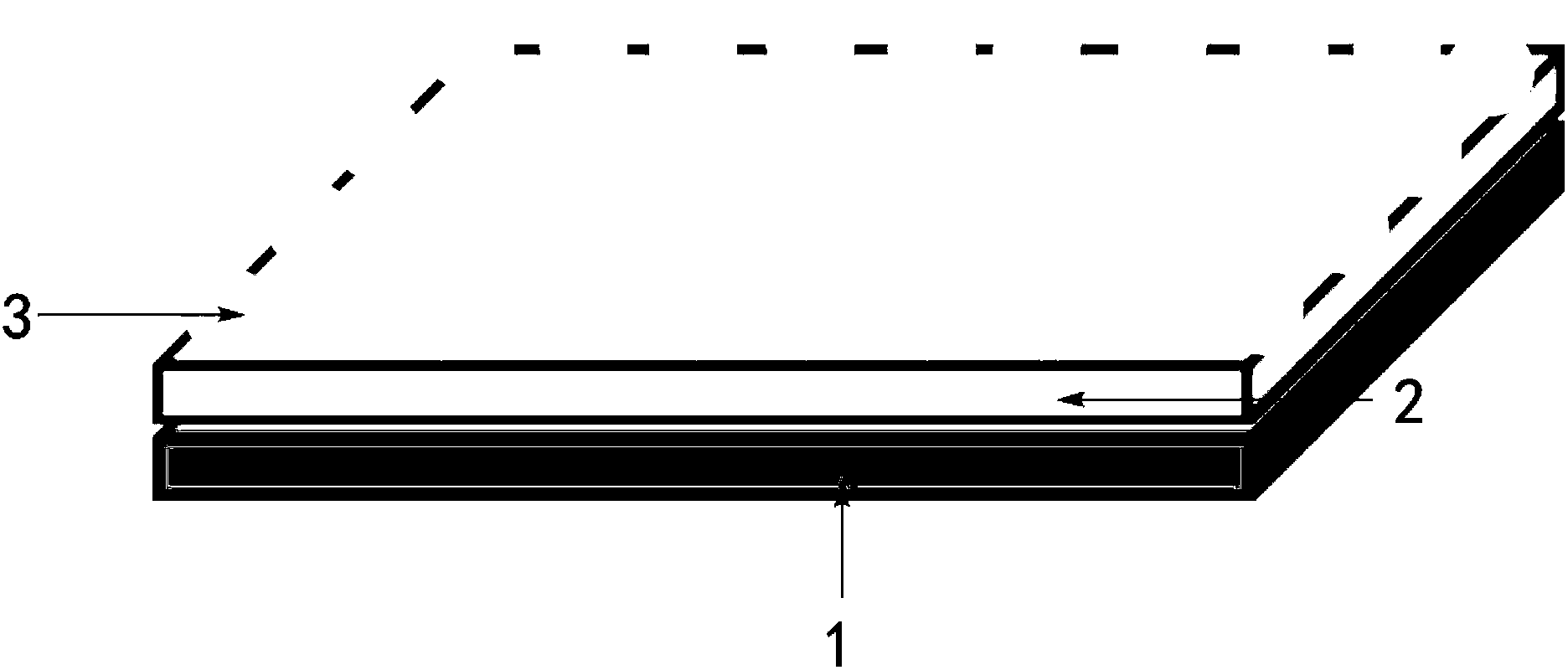

Method for preparing high temperature resistant composite separator by lithium ion battery

A lithium-ion battery and composite separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high equipment requirements, weak adhesion, and high equipment requirements, and achieve improved cycle performance, lyophilicity. The effect of improving performance and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

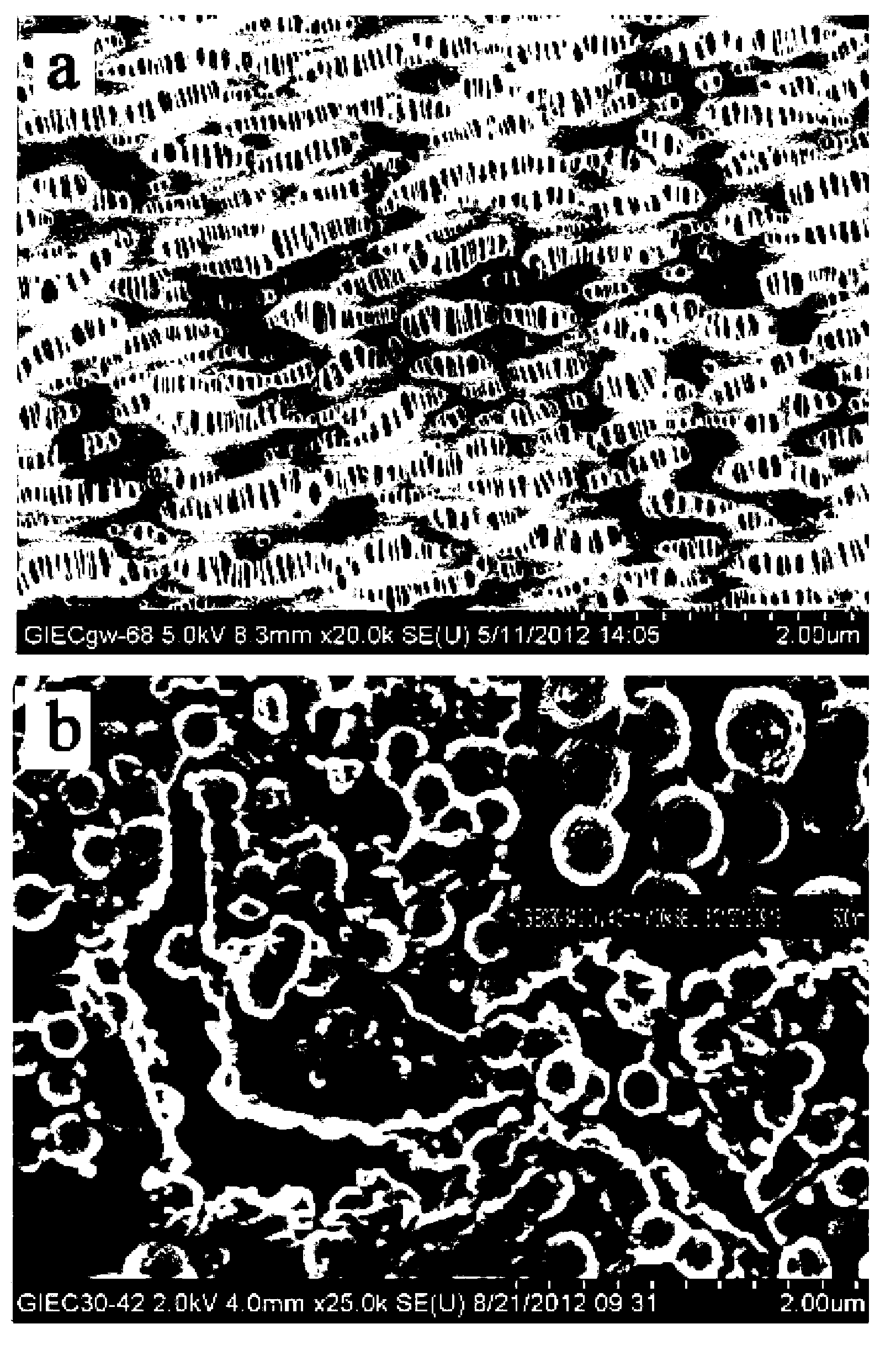

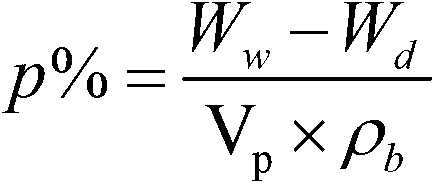

[0051] (1) Surface pretreatment of the matrix membrane: 1.5g / L methacryloyl dopamine solution was prepared at room temperature; Soak in methacryloyl dopamine solution for 24 hours, wash off the methacryloyl dopamine attached to the surface with distilled water, and dry naturally to obtain a modified film; immerse the modified film in 3% K 2 CO 3 Treat in the solution for 60 minutes to obtain a pretreated microporous membrane;

[0052] (2) sol-gel introduces silica coating: add H successively 2 O / EtOH / HCl mixed solution and TEOS (molar ratio is 16:4:0.17:1), after stirring and mixing, add 3-(methacryloyloxy)propyltrimethoxysilane and γ-aminopropyl Triethoxysilane (the dosage is 5% of the weight of silica), seal and stir the reaction, and add SiO with a particle size of 50nm after an interval of 2h 2 powder (the amount is 50% of the mass of tetraethyl orthosilicate), continue to stir and react for about 24 hours, add polyethylene glycol dimethyl ether (the amount is 30% of th...

Embodiment 5

[0054] (1) Surface pretreatment of the substrate membrane: prepare 2.5g / L dopamine solution at room temperature; soak the PE microporous membrane (obtained by self-made in Comparative Example 1, porosity 55%, pore diameter 0.2μm) in the dopamine solution After 24 hours, the dopamine attached to the surface was washed away with distilled water, and dried naturally to obtain a modified film; the modified film was immersed in 5% K 2 CO 3 Treat in the solution for 40 minutes to obtain a pretreated microporous membrane;

[0055] (2) sol-gel introduces silica coating: add H successively 2 O / CH 3 OH / HCl mixed solution and TEOS (24:4:0.085:1), stir and mix well, add γ-glycidyl etheroxypropyl trimethoxysilane vinyl trimethoxysilane and γ-aminopropyl triethyl Oxysilane (the amount is 10% of the weight of silica), seal and stir the reaction, add SiO with a particle size of 150nm after an interval of 4h 2 Powder (the amount is 50% of the mass of tetraethyl silicate), continue to stir ...

Embodiment 6

[0057] (1) Surface pretreatment of the matrix membrane: 3 g / L methyl dopamine solution was prepared at room temperature; PE microporous membrane (obtained by self-made in Comparative Example 1, porosity 55%, pore diameter 0.2 μm) was mixed with methyl dopamine solution Soak in medium for 24 hours, wash off the methyldopamine attached to the surface with distilled water, and dry naturally; immerse the modified membrane in 10% K 2 CO 3 Treat in the solution for 20 minutes to obtain a pretreated microporous membrane;

[0058] (2) sol-gel introduces silica coating: add H successively 2 O / EtOH / HCl mixed solution and TEOS (24:4:0.085:1), stirring and mixing, successively add γ-glycidyl etheroxypropyltrimethoxysilane vinyltrimethoxysilane and γ-aminopropyl Triethoxysilane (the dosage is 10% of the weight of silica), seal and stir the reaction, and add SiO with a particle size of 260nm after an interval of 4h 2 powder (the amount is 60% of the mass of tetraethyl orthosilicate), con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com