Preparation method of expanding microporous poly tetrafluoroethylene

A polytetrafluoroethylene membrane and microporous technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. and other problems, to achieve the effect of high uniformity, high tensile breaking strength, and improved product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

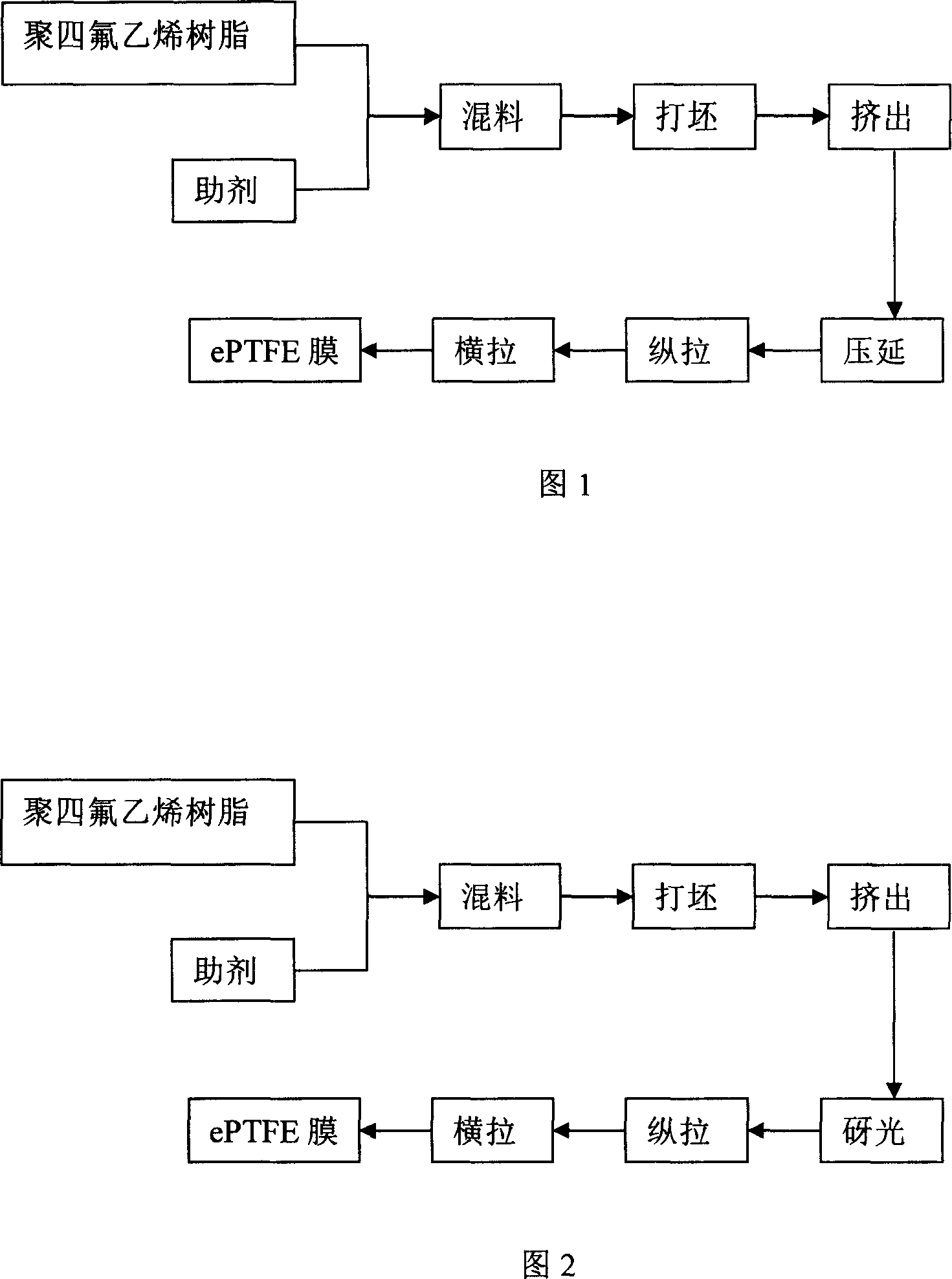

Method used

Image

Examples

Embodiment 1

[0033] The raw material of polytetrafluoroethylene resin used in this example is a commercially available high molecular weight (molecular weight: 8,000,000) dispersed polytetrafluoroethylene resin, and the auxiliary agent is a mixture of aromatic hydrocarbon isoparaffin and aviation kerosene. Follow these steps:

[0034] (1) Mixing: Fully stir the high molecular weight polytetrafluoroethylene resin and the auxiliary agent in a mixer in a ratio of 100:30;

[0035] (2) Blanking: Put the raw materials uniformly mixed in the previous process into an oven (at a temperature of 40°C) and fully infiltrate them for 12 hours, and make a cylindrical green body with a diameter of 104mm through a preforming device;

[0036] (3) Extrusion: Extrude with a flat die with a flat die with an aspect ratio of 70:1, the compression ratio is 10, and the extrusion speed is 1m / min, so that the cylindrical body is transformed into a flat sheet The sheet is 244mm wide and 3.48mm thick, and the extrusi...

Embodiment 2

[0041] The steps are the same as those in Example 1, and its process parameters are compared with those in Example 1, except for the following differences. The difference is that the selected compression ratio in the extrusion step is 30, the width of the extruded sheet is 200 mm, the thickness is 1.4 mm, and the thickness of the prepared film is 22.5 μm.

Embodiment 3

[0043] The steps are the same as those in Example 1, and its process parameters are compared with those in Example 1, except for the following differences. The difference is that the diameter of the cylindrical body made by the preforming device is 60 mm, the extruded sheet is 200 mm wide and 1.4 mm thick, and the prepared film thickness is 21.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com