dust suppressant

A technology of dust suppressant and cross-linking agent, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as threats to personal safety, pollution, dust pollution, etc., to avoid dust pollution, high viscosity, and low wind erosion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

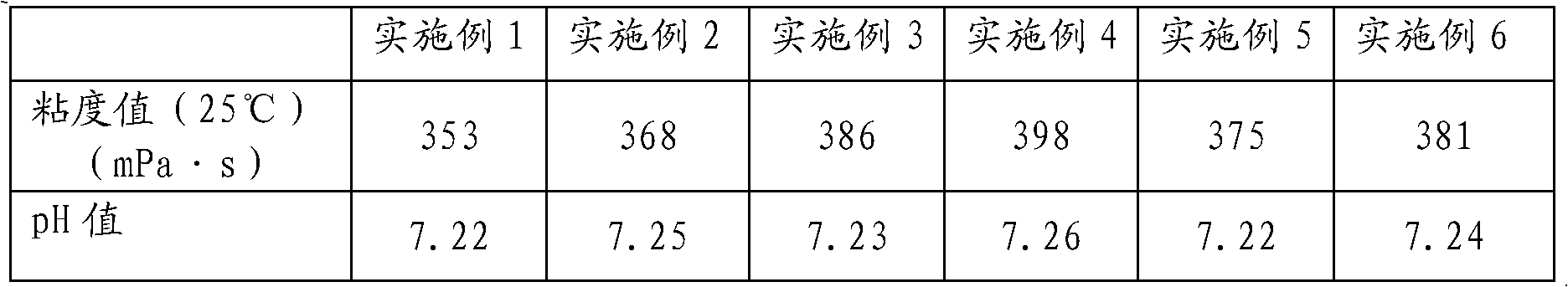

Embodiment 1

[0026] First add 98.82g tap water to the preparation tank, start stirring, then add 0.7g squash gum, 0.3g sodium carboxymethyl cellulose, 0.05g aluminum chloride, 0.08g sodium aluminosilicate, 0.05g sodium carboxymethyl starch , Stir for 1h to fully dissolve the materials to obtain the finished product.

Embodiment 2

[0028] First add 98.79g tap water to the preparation tank, start stirring, then add 0.8g squash gum, 0.2g sodium carboxymethyl cellulose, 0.06g aluminum chloride, 0.09g sodium aluminosilicate, 0.06g sodium carboxymethyl starch , Stir for 0.5h to fully dissolve each material to obtain the finished product.

Embodiment 3

[0030] First add 98.80g tap water in the preparation tank, start stirring, then add 0.75g guar gum, 0.25g sodium hydroxypropyl methylcellulose, 0.05g sodium tetraborate, 0.09g silicon dioxide, 0.06g polyvinyl alcohol, Stir for 0.5h to fully dissolve each material to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com