Positive electrode material recovering method for waste lithium ionic cell

A lithium-ion battery and cathode material technology, which is applied in the field of recycling waste battery cathode materials, can solve the problems of long recycling process and high recycling cost, and achieve the effect of simple recycling method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example illustrates the recovery method of the positive electrode material of the spent lithium ion battery.

[0024] Soak 16 kilograms of LP463446ARU waste lithium-ion batteries (the positive electrode material is lithium cobalt oxide) in 35 kilograms of sodium chloride aqueous solution (the content of sodium chloride is 36.5% by weight) for 2 hours.

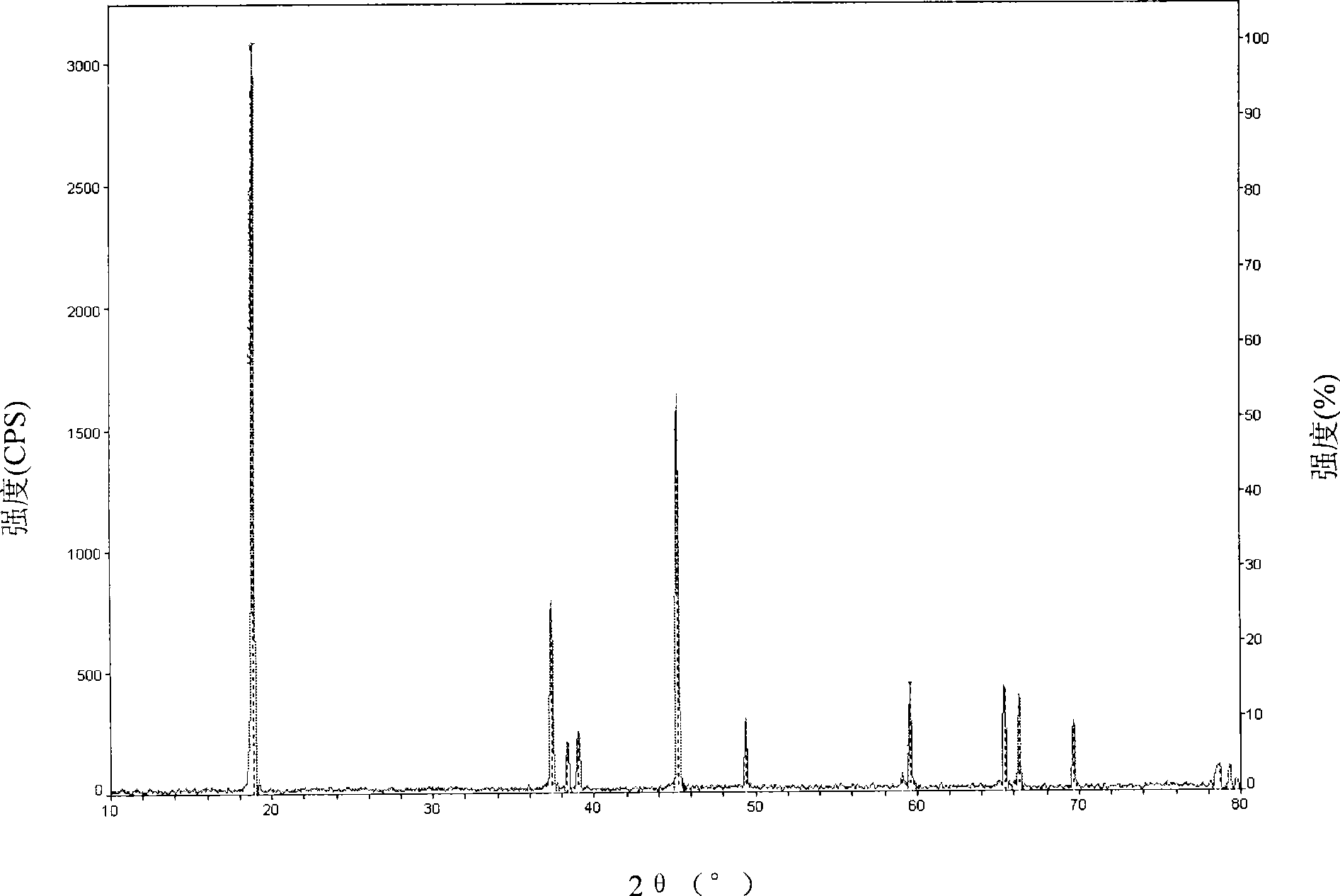

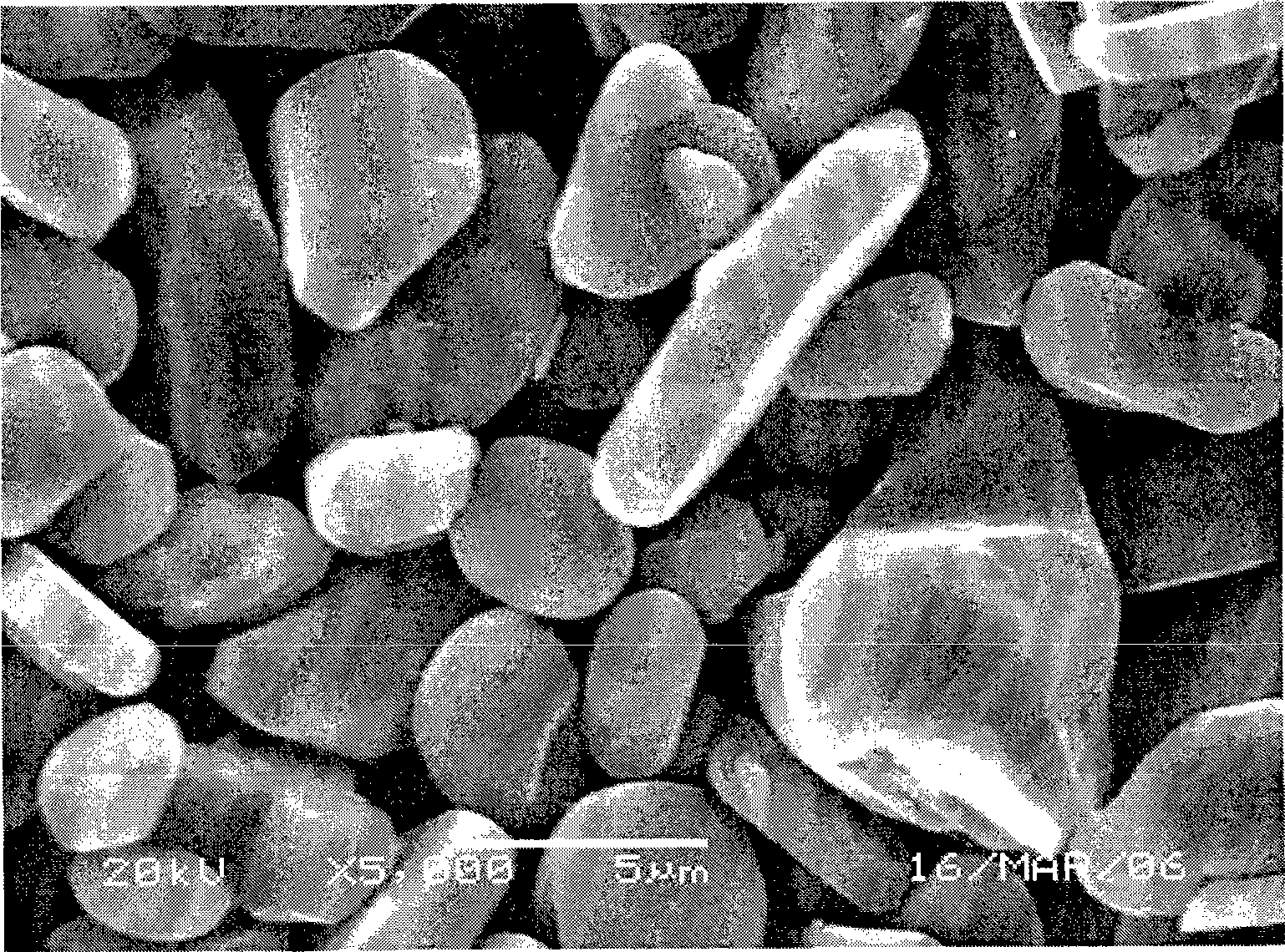

[0025] Cracks appear at the contact between the positive and negative electrodes of the battery, take out the battery and remove the battery case, separate the positive electrode sheet 6.5 kg, soak the positive electrode sheet in 15 kg of N-methylpyrrolidone at 70°C for 6 hours, and put the positive electrode material After elution, the current collector was taken out, and then filtered to obtain 5.66 kg of black powder. This black powder was mixed with 15 kg of hydrochloric acid solution (the concentration of hydrochloric acid was 30% by weight) for 30 minutes, so that the black powder was fully dissolved to obtain...

Embodiment 2

[0028] The recovery of the positive electrode material of the spent lithium ion battery was performed according to the method of Example 1, except that the aqueous electrolyte solution was an aqueous solution of sodium nitrate, wherein the content of sodium nitrate was 45% by weight.

[0029] The LiCoO 2 The X-ray diffraction analysis figure and scanning electron microscope figure of powder sample and the LiCoO that make in embodiment 1 2 Powder samples are similar.

Embodiment 3

[0031] According to the method of Example 1, the positive electrode material of the waste lithium ion battery is recovered, the difference is that the aqueous electrolyte solution is an aqueous solution of potassium sulfate, wherein the content of potassium sulfate is 10% by weight, and the soaking time is 5 hours.

[0032] The LiCoO 2 The X-ray diffraction analysis figure and scanning electron microscope figure of powder sample and the LiCoO that make in embodiment 1 2 Powder samples are similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com