Laminating apparatus, and laminating method using it

A technology for lamination devices and laminates, applied in lamination devices, laminations, lamination systems, etc., can solve the problem of residual air bubbles, lamination materials 95 clinging and following, film materials clinging and following circuit boards 82 and other problems, to achieve the effect of excellent adhesion, improved adhesion followability, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

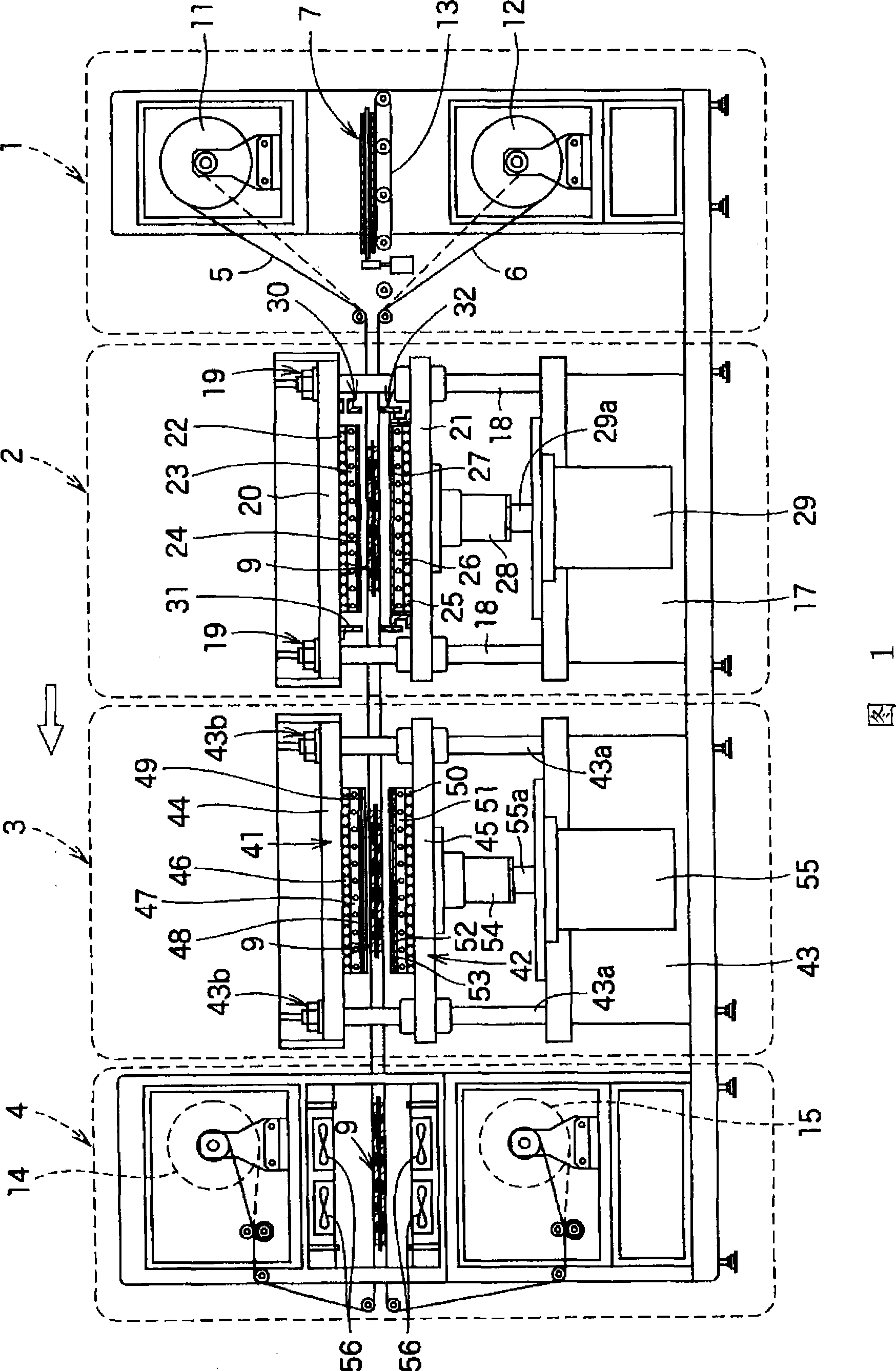

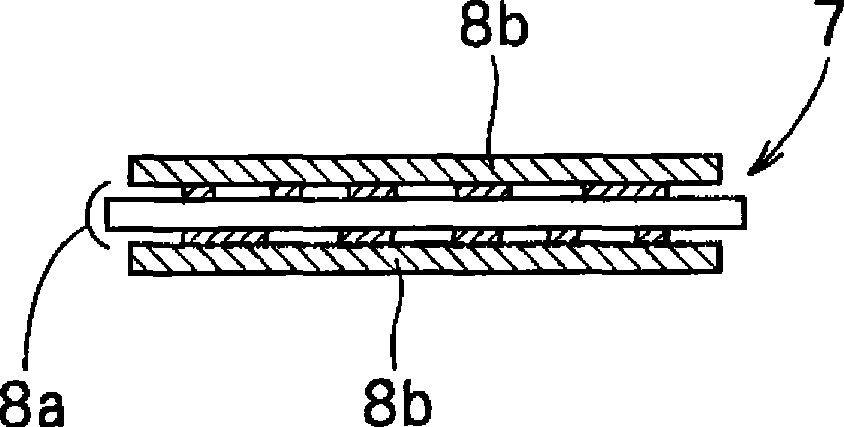

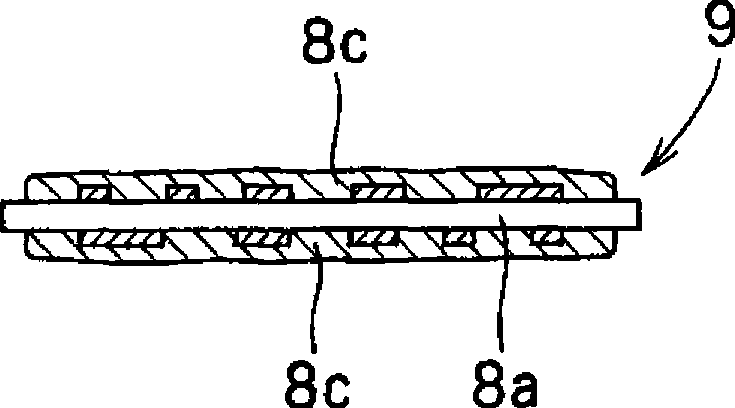

[0130] The vacuum laminator 2 and the flat presser 3 shown in FIG. 1 were used. The space part 34 was previously adjusted to 110 degreeC by the hot plate 23,26 of the upper and lower plates 20,21 of the vacuum laminator 2. First, a film-shaped resin material 8b composed of a thermosetting resin composition (glass transition temperature: 80°C) and a polyethylene terephthalate support film is placed on both front and back surfaces of a substrate 8a having concavo-convex surfaces. , the thermosetting resin composition is made of epoxy resin, and the resin surface of the two film-like resin materials 8b (the thickness of the resin layer is 38 μm) and the uneven surface of the above-mentioned substrate 8a (the thickness of the uneven 18 μm, and the interval of unevenness is 20 μm) and temporarily fixed by contacting, and the temporary laminated body 7 was prepared.

[0131] Next, the above-mentioned temporary laminated body 7 is transported into the vacuum lamination device 2 by u...

Embodiment 2

[0154] Under the conditions of Example 1, the substrate 8a was placed in the central part of the hot plates 23, 26 of the vacuum laminator 2, and after running 300,000 times, the laminated body 9 obtained under the conditions of Example 1 was similarly Followability, film thickness uniformity, surface specularity, and generation of wrinkles were evaluated.

Embodiment 3

[0156] Under the conditions of Example 2, except for the upper and lower elastic pressure plates 24 and 27 of the vacuum laminator 2, a fluorine-containing silicone with a Shore A hardness of 60 degrees, a thickness of 4 mm, and a surface roughness Rz of 3 μm The rubber is vulcanized and bonded to one side of a stainless steel plate (SUS630H, thickness 2 mm) with a flatness of 3 μm, and the surface of the unvulcanized side of the fluorine-containing silicone rubber is bonded, and "KINYO BOARDF200" manufactured by Jinyang Company is used as a cushioning material (dimensions (vertical x horizontal) 63 cm x 63 cm) were fixed outside the upper and lower hot plates 23 and 26, and the laminated body 9 was formed under the same conditions, and the followability, film thickness uniformity, surface specularity, and wrinkle were similarly evaluated. produce.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com