Custom-decorated giftwrap, kit, and method of and system for custom-decorating the giftwrap

a gift wrapping and custom-decorated technology, applied in the field of custom-decorated gift wrapping, a kit for making the gift wrapping, and a custom-decorated gift wrapping method and system, can solve the problems of inconvenient use, inelegant taping of separate sheets, and limiting factors in terms of the maximum size of custom-decorated products, etc., to achieve the effect of convenient design and us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

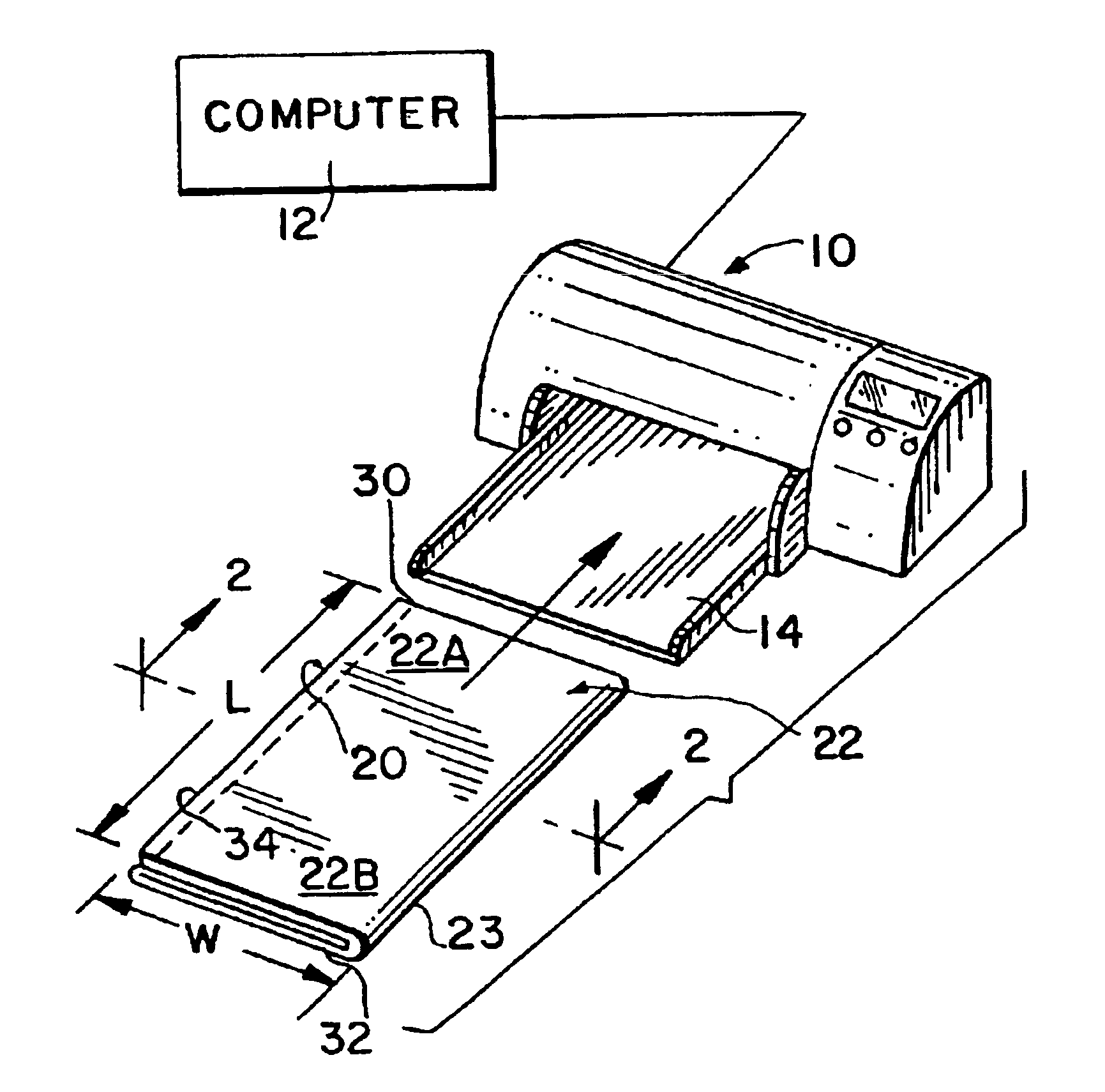

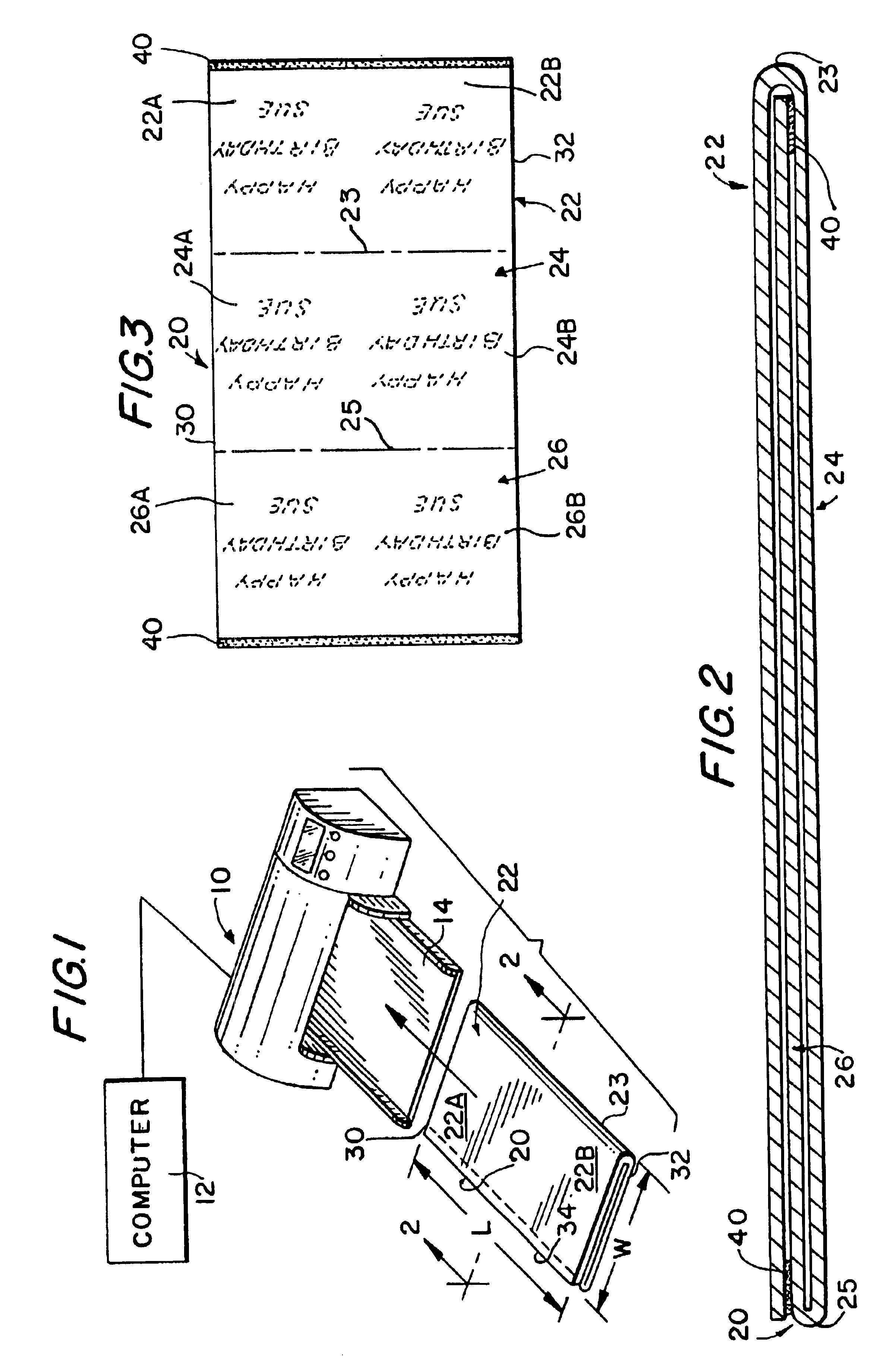

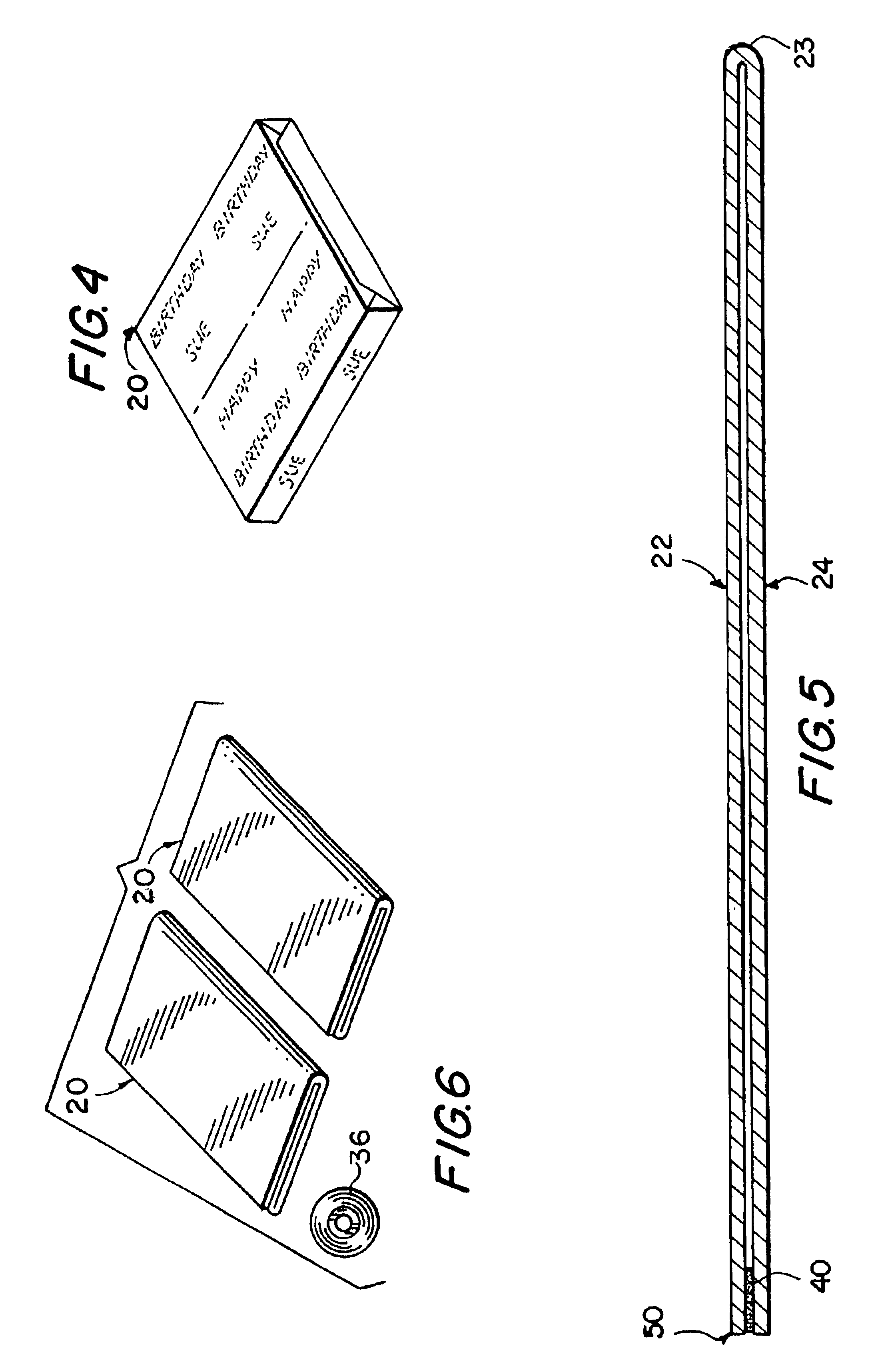

[0027]Reference numeral 10 depicts an inkjet printer of conventional design and connected to a computer 12. A folded sheet 20 is depicted during insertion into a paper loading tray 14 of the printer. As explained below, the folded sheet 20 will be printed with a custom decoration, e.g., multiple printings of the designation “Happy Birthday Sue”, to form the giftwrap depicted in FIG. 3. Thereupon, the giftwrap is fitted around a giftbox, as shown in FIG. 4, to complete the personalized gift presentation.

[0028]The printer 10, which could also be a laser jet printer, is of the size and type commonly found at home, wherein the maximum paper width (W) is 8½″. The folded sheet 20 has at least two panels or sheet portions, namely an upper sheet portion 22 and a lower sheet portion 24, both of equal area and folded about a longitudinal fold line 23 to overlap each other. Preferably, the folded sheet 20 has a third panel or sheet portion, namely middle sheet portion 26, of equal area to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com