Dehulling method of fresh pepper fruit

A pepper fresh fruit, pepper technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of water consumption in the processing process, poor appearance, color and quality, and long processing cycle, so as to reduce sewage discharge , enhance market competitiveness, and promote the effect of industrial upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

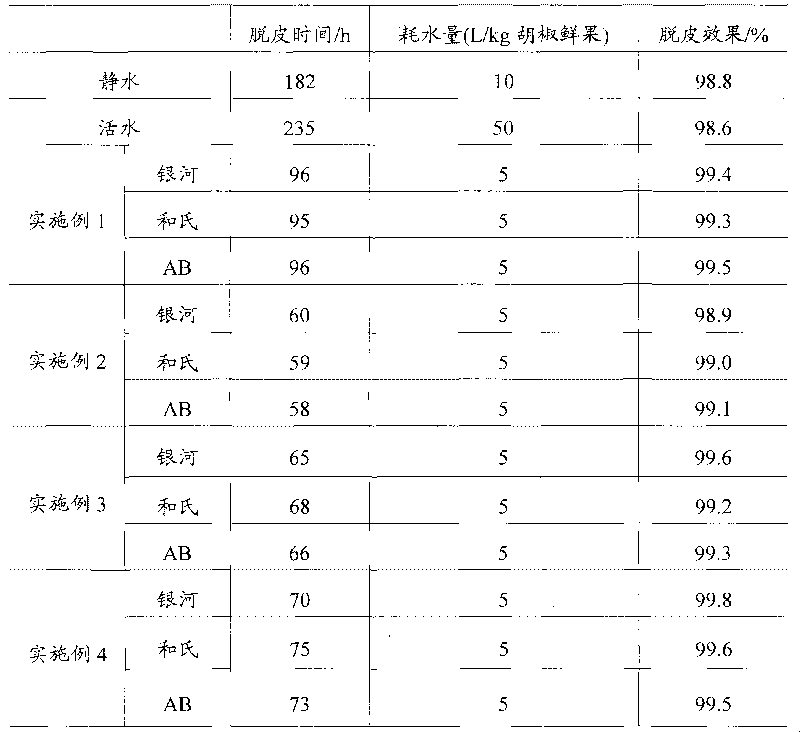

Embodiment 1

[0018] (1) Raw material selection

[0019] Select mature ears that conform to the "Technical Regulations for Pepper Cultivation" (NY-T 969-2006), that is, at least 2 to 4 ears that turn red or the whole ear turns yellow.

[0020] (2) Soaking in enzymolysis solution

[0021] a: Add pectinase to water, stir evenly, and make a pectinase hydrolyzate with a volume concentration of 3‰;

[0022] b: adjust the pH value of the pectin enzymatic hydrolysis solution to 5.5 with citric acid solution and sodium bicarbonate solution;

[0023] c: Soaking the ripe fruit ears in the prepared pectin enzymatic hydrolysis solution according to the weight ratio of fruit ears and pectin enzymatic hydrolysis solution of 1:2;

[0024] d: Soak at 30°C for 96 hours. During this period, adjust the pH of the pectin enzymatic hydrolysis solution with citric acid solution and sodium bicarbonate solution every 12 hours, keep the pH at 5.5, and stir the pectin enzymatic hydrolysis solution from time to time...

Embodiment 2

[0032] (1) Raw material selection

[0033] Select mature ears that conform to the "Technical Regulations for Pepper Cultivation" (NY-T 969-2006), that is, at least 2 to 4 ears that turn red or the whole ear turns yellow.

[0034] (2) Constant temperature soaking in enzymatic hydrolysis solution

[0035] a: Add pectinase to water, stir evenly, and make a pectinase hydrolyzate with a volume concentration of 1‰;

[0036] b: Soaking the mature fruit ears in the prepared pectin enzymatic hydrolysis solution according to the weight ratio of fruit ears and pectin enzymatic hydrolysis solution of 1:3;

[0037] c: heat up the pectin enzymatic hydrolysis solution to 40° C., soak at a constant temperature for 60 hours, during which time, stir the pectin enzymatic hydrolysis solution every 12 hours.

[0038] (3) Peeling and washing

[0039] After soaking, remove the peppercorns, remove the skin, stems and other sundries, and wash until clean.

[0040] (4) Bleaching

[0041] The washe...

Embodiment 3

[0045] (1) Raw material selection

[0046] Select mature ears that conform to the "Technical Regulations for Pepper Cultivation" (NY-T 969-2006), that is, at least 2 to 4 ears that turn red or the whole ear turns yellow.

[0047] (2) Constant temperature and pH soaking in enzymatic hydrolysis solution

[0048] a: Add pectinase to water, stir evenly, and make a pectinase hydrolyzate with a volume concentration of 5‰;

[0049] b: adjust the pH value of the pectin enzymatic hydrolysis solution to 6.0 with citric acid solution and sodium bicarbonate solution;

[0050] c: according to the weight ratio of fruit ears and pectin enzymatic hydrolysis solution being 1:1, soaking mature fruit ears below the liquid surface of the prepared pectin enzymatic hydrolysis solution;

[0051] d: Heat up the pectin enzymolysis solution to 40°C, soak at a constant temperature for 65 hours, during which time, adjust the pH of the pectin enzymolysis solution with citric acid solution and sodium bic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com