Process for preparing layered silicon nitride ceramic with high strength and high toughness by utilizing component gradient design

A technology of silicon nitride ceramics and high toughness, applied in the direction of ceramic layered products, layered products, chemical instruments and methods, etc., can solve the limited application range, the brittle defects of silicon nitride ceramics have not been completely improved, compressive stress The effect is not obvious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Step 1: the commercially available α-Si 3 N 4 , α-Al 2 o 3 , Y 2 o 3 According to the proportions in Table 3, use absolute ethanol as the dispersion medium, silicon nitride balls with a diameter of 2-3mm as the grinding medium, and ball mill in a nylon tank to control the particle size of the material to D50=0.2μm;

[0013] Table 3 Ingredients List (%)

[0014] Numbering α-Si 3 N 4 α-Al 2 o 3 Y 2 o 3 0# 85 8 7 1# 87 7 6 2# 90 6 4

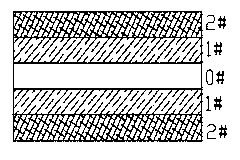

[0015] Step 2: Add 5wt% polyvinyl alcohol (PVA) solution with a concentration of 3wt% to the above three mixed materials as a temporary binder. Follow the instructions figure 1 Add the materials corresponding to various numbers in the charging sequence, and press it into a block with an isostatic press at 100MPa, and the thickness of each layer after pressing should be controlled to about 2mm;

[0016] Step 3: Put the pressed sample into the pressure sintering furnace for pressure sin...

Embodiment 2

[0018] Step 1: the commercially available α-Si 3 N 4 , α-Al 2 o 3 , Y 2 o 3 According to the proportions in Table 4, use absolute ethanol as the dispersion medium, silicon nitride balls with a diameter of 2-3 mm as the grinding medium, and ball mill in a nylon tank to control the particle size of the material to about D50=0.2 μm;

[0019] Table 4 Ingredients list (%)

[0020] Numbering α-Si 3 N 4 α-Al 2 o 3 Y 2 o 3 0# 82 10 8 1# 85 8 7 2# 89 6 5

[0021] Step 2: Add 6wt% polyvinyl alcohol (PVA) solution with a concentration of 3wt% to the above three mixed materials as a temporary binder. Follow the instructions figure 1 Add the materials corresponding to various numbers in the charging sequence, and press it into a block with an isostatic press at 100MPa, and the thickness of each layer after pressing should be controlled to about 2mm;

[0022] Step 3: Put the pressed sample into the pressure sintering furnace for pre...

Embodiment 3

[0024] Step 1: the commercially available α-Si 3 N 4 , α-Al 2 o 3 , Y 2 o 3 According to the proportions in Table 5, use absolute ethanol as the dispersion medium, silicon nitride balls with a diameter of 2-3 mm as the grinding medium, and ball mill in a nylon tank to control the particle size of the material to about D50=0.2 μm;

[0025] Table 5 Ingredients list (%)

[0026] Numbering α-Si 3 N 4 α-Al 2 o 3 Y 2 o 3 0# 84 9 7 1# 88 7 5 2# 92 4 4

[0027] Step 2: Add 7wt% polyvinyl alcohol (PVA) solution with a concentration of 3wt% to the above three mixed materials as a temporary binder. Follow the directions figure 1 Add the materials corresponding to various numbers in the charging sequence, and press it into a block with an isostatic press at 100MPa, and the thickness of each layer after pressing should be controlled to about 2mm;

[0028] Step 3: Put the pressed sample into the pressure sintering furnace for pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com