Cracking-resistant multifunctional impregnated bond paper decorative face artificial board and manufacturing method thereof

A technology of impregnating film paper and wood-based panels, which is applied in the direction of manufacturing tools, chemical instruments and methods, and other plywood/plywood appliances, etc., and can solve the constraints on the industrial production of environmentally friendly high value-added products and the low pass rate of industrial production , uneven distribution of moisture content of the base material, etc., to achieve the effect of improving the comfort of use, improving the electrical conductivity, and good antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Select plywood as the base material, adjust the moisture content of the base material to 7%, and sand it with a thickness of 12mm; select the structure of two carbon fiber material layers on the upper and lower sides of the base material.

[0043] Step 2: Cut the carbon fiber material, semi-cured film, and impregnated film paper, the length and width of which are 5mm larger than those of the plywood base material, among which the melamine resin film is used as the semi-cured film, and the modified melamine urea-formaldehyde resin is selected Adhesive paper is used as impregnated adhesive film paper.

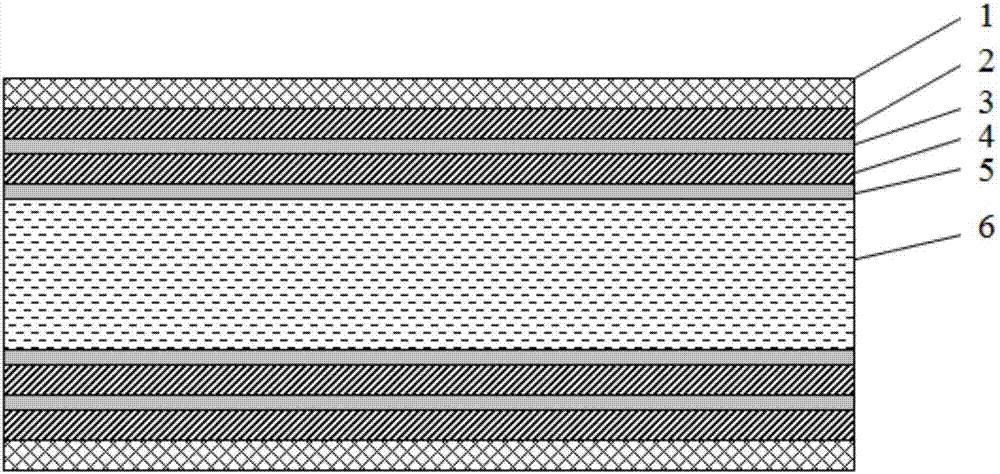

[0044] Step 3: Carry out blank assembly, from top to bottom: impregnated film paper, carbon fiber material, semi-cured film, carbon fiber material, semi-cured film, plywood substrate, semi-cured film, carbon fiber material, semi-cured film , carbon fiber material, impregnated film paper.

[0045] Wherein, the carbon fiber material layer is selected from a paper fi...

Embodiment 2

[0049] Step 1: Select plywood as the base material, adjust the moisture content of the base material to 7%, and sand it with a thickness of 12mm; select technical veneer as the wooden buffer layer, and adjust the moisture content of the wooden buffer layer within the range of 7%.

[0050] Step 2: Cut the wooden buffer layer, carbon fiber material, prepreg film, and impregnated film paper, the length and width of which are 5mm larger than those of the wood-based panel base material, and the melamine resin film is used as the prepreg film, and the The modified urea-formaldehyde resin is used as the adhesive layer of the substrate, and the modified melamine resin impregnated film paper is selected as the impregnated film paper.

[0051] Step 3: Carry out blank assembly, from top to bottom, impregnated film paper, carbon fiber material, semi-cured film, wooden buffer layer, adhesive layer coated on the base material, base material, adhesive layer coated on the base material , wood...

Embodiment 3

[0056] Step 1: Select plywood as the base material, adjust the moisture content of the base material to 15%, and sand it with a thickness of 12mm; select technical veneer as the wooden buffer layer, and adjust the moisture content of the wooden buffer layer within the range of 15%.

[0057] Step 2: Cut the wooden buffer layer, carbon fiber material, prepreg film, and impregnated film paper. The length and width are 5mm larger than the wood-based panel base material, and the melamine resin prepreg film is used as the prepreg film , choose melamine resin impregnated film paper as the impregnated film paper.

[0058] Step 3: Carry out blank assembly, from top to bottom: impregnated film paper, carbon fiber material, semi-cured film, carbon fiber material, semi-cured film, wood-based panel base material, semi-cured film, carbon fiber material, semi-cured glue film, carbon fiber material, impregnated film paper.

[0059] Wherein, the carbon fiber material layer is selected from a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com