Composite insulator

A technology of composite insulators and suspension insulators, applied in the direction of suspension/strain insulators, etc., can solve problems such as inability to transform insulators, excessive research and development costs and time, and inability to apply insulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

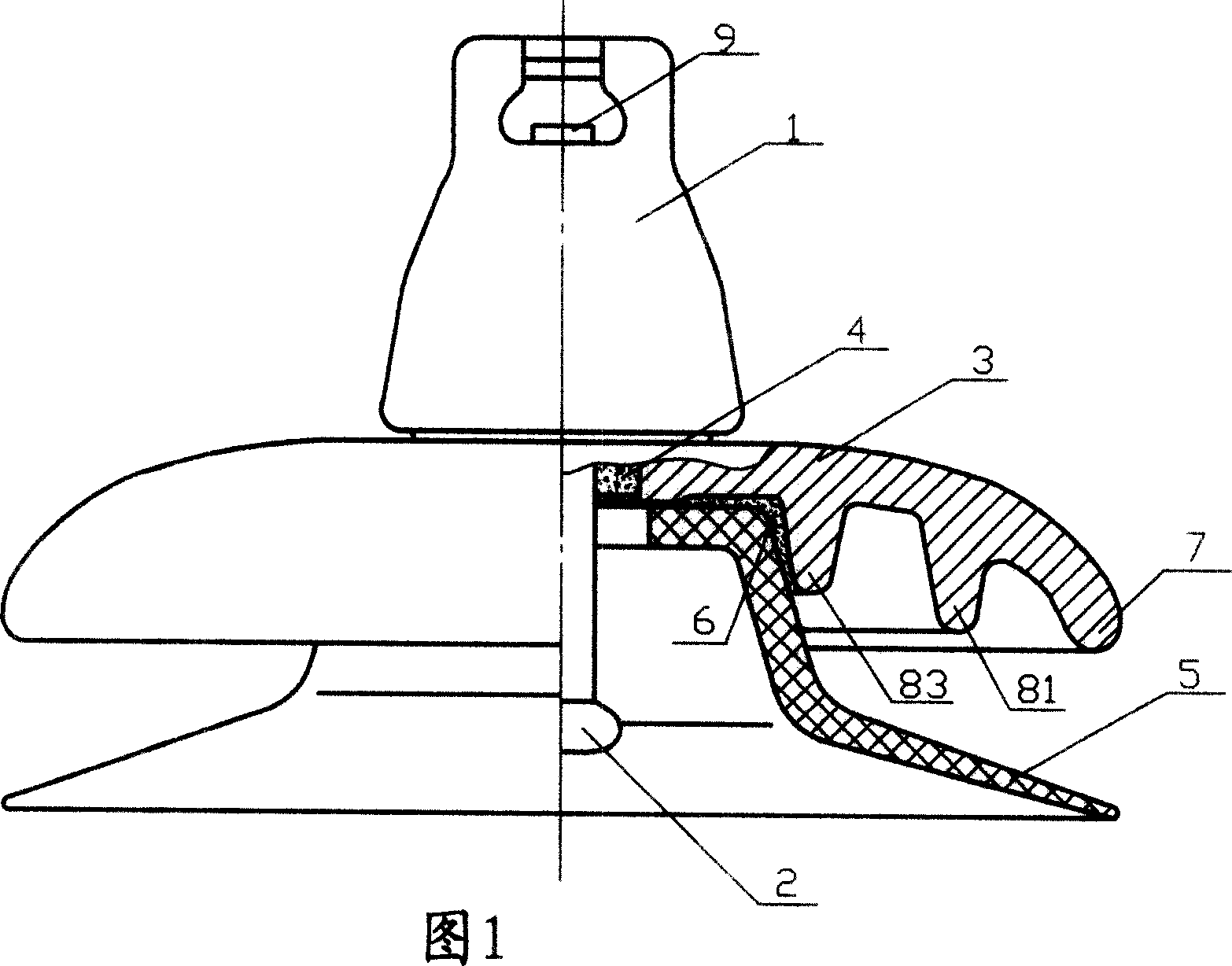

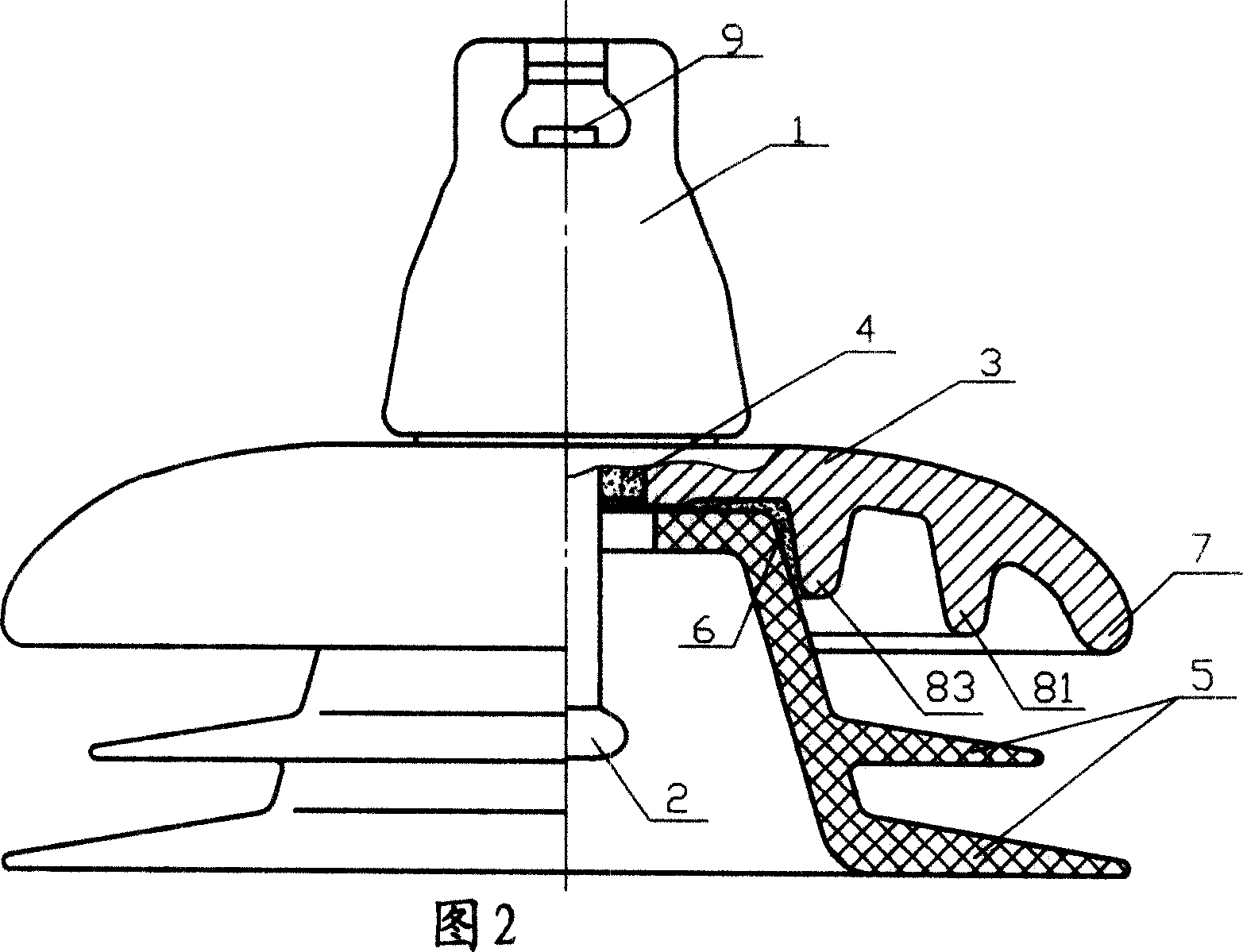

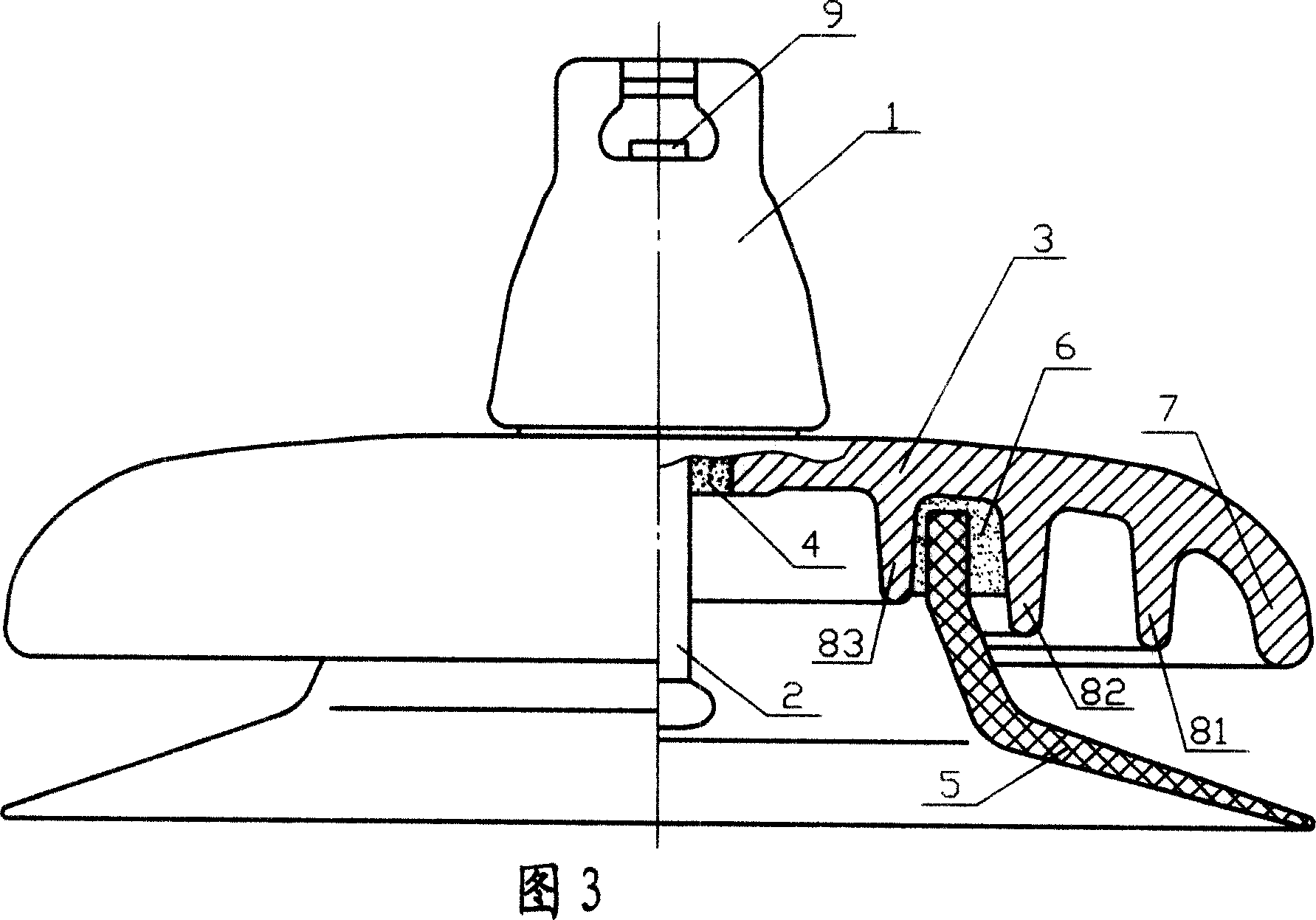

[0024] In accompanying drawing 1, iron cap 1, steel foot 2, umbrella dish 3 and adhesive packing material 4 have formed a single-layer umbrella dish shape suspension insulator (9 is locking pin pin mouth) together. The lower surface of the umbrella disk 3 of the suspension insulator has two downwardly protruding annular umbrella edges, that is, an outer umbrella edge 81 and an inner umbrella edge 83 , and a downwardly extending annular drip edge 7 . The structural height (note: this word is technical term) of this suspension insulator is 146 millimeters, and the diameter of umbrella disk 3 is 255 millimeters. The middle hole of synthetic shed 5 extends upwards in a tubular shape, and the top of the tubular extension and the lower surface of the umbrella disc 3 of said suspension insulator are bonded to each other by adhesive 6 (all sides of the ring-shaped umbrella edge are bonded together in the present invention) Both the surface and the lower surface are regarded as part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com