Method for detecting composite insulator interface defect

A technology for composite insulators and interface defects, applied in the direction of material breakdown voltage, etc., can solve the problems of inability to sensitively point out the hidden dangers of early interface defects of composite insulators, and achieve the effects of low detection cost, high fitting precision, and high accuracy

Inactive Publication Date: 2012-06-20

WUHAN UNIV +1

View PDF2 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In recent years, some new detection methods: such as ultraviolet imaging method is suitable for defects that can generate partial discharge, infrared imaging method is suitable for defects that can generate local heating, electric field method is suitable for conductive internal insulation defects, etc. These tests and methods are in To a certain extent, it can also reflect the interface defects of composite insulators, but the relevant research and practical application results show that the above tests and methods can only reflect the situation when the interface defects of composite insulators develop to a relatively serious level, and cannot sensitively point out Potential hidden dangers of early interface defects in composite insulators

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

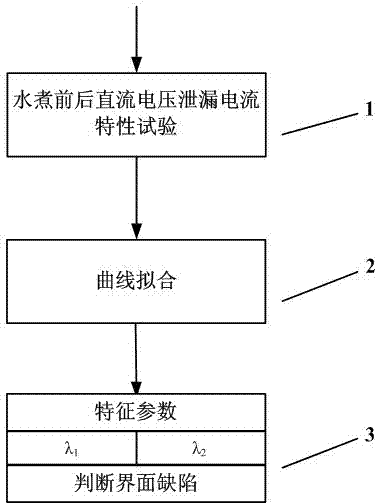

[0033] see figure 1 , the composite insulator interface defect detection process of the embodiment of the present invention includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

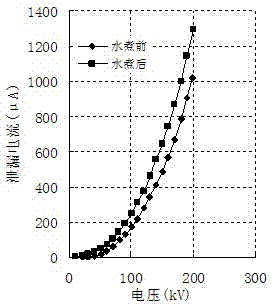

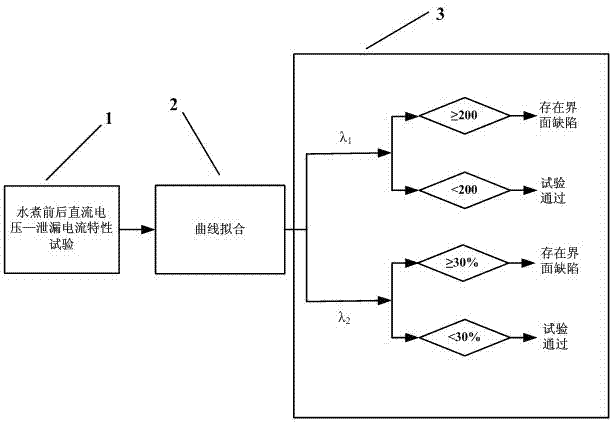

The invention discloses a method for detecting composite insulator interface defects; according to the method, DC voltage leakage current characteristic tests of a composite insulator before and after a water boiling test are performed; power function fitting of the DV voltage and corresponding leakage current data and curves obtained in the measurement is performed; interface defects of the composite insulator are discriminated according to the fitting results; and discrimination determination can be performed by using characteristic coefficient ratios or characteristic index change rates. The method provided by the invention overcomes the disadvantage that withstand voltage tests and steep impulse tests can not sensitively reflect composite insulator interface defects; the method of the invention is simple and effective, and is applicable to the detection of 35-1000 kV AC-DC composite insulator interface defects.

Description

technical field [0001] The invention relates to a detection method for a composite insulator, in particular to a method for detecting defects at the interface between a silicone rubber shed and a protective layer and between a silicon rubber shed and an epoxy rod of a composite insulator. Background technique [0002] Composite insulator is composed of three parts: core rod, shed sheath and fittings. The contact surface between different materials of composite insulator is called interface. The early composite insulators used the single umbrella bonding vacuum filling process, and there were many interfaces, such as between the mandrel and the umbrella cover, between various parts of the umbrella cover, between the sheds, between the umbrella cover and the umbrella cover, and between the umbrella cover and the umbrella cover. 1. The interface between the mandrel and the metal accessory has high process requirements, and it is easy to cause internal insulation breakdown due ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/92

Inventor 王建国贾伯岩周剑何瑞东郑雄伟胡聪

Owner WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com