Silicone rubber composite insulator aging degree detection method

A composite insulator, aging degree technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of inability to quantitatively describe the aging degree of composite insulators, obvious fault detection effect, unsatisfactory detection effect, etc., to achieve easy operation and simple method , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

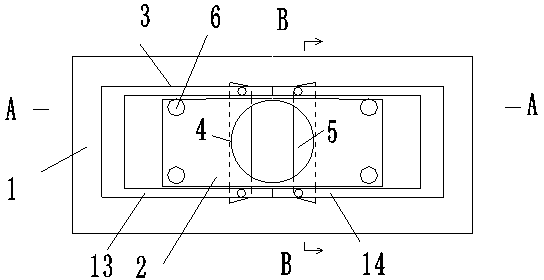

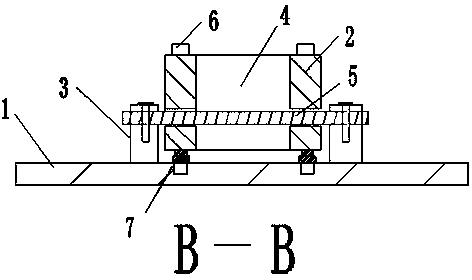

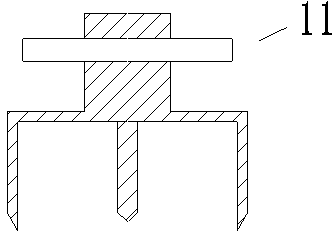

[0024] see Figure 1 ~ Figure 4 , the present invention must at first prepare sample before testing, used special-purpose sampler and slicing mechanism when preparing sample, and wherein, sampler 11 is used for cutting sample blank, and slicing mechanism is used for sample blank tidy. The slicing mechanism includes a cutting part, a bottom plate 1 and a pressing part, the pressing part is used to press and fix the sample blank; the cutting part is used to trim the thickness and surface of the sample blank, and the cutting part consists of The sliding blade holder 3 and the sample blank fixing frame 2 are composed, and the outer wall of the sample blank fixing frame 2 is slidably matched with the inner wall of the sliding blade holder 3 . Wherein, the sample blank fixing frame 2 is fixed on the bottom plate 1 by bolts 6, and the sample blank fixing frame is provided with a sample blank placement opening 4 and a blade sliding groove 13, and the sample blank placement opening 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com