Organic and inorganic hybrid microsphere particle, preparation and application thereof

A technology for hybridizing microspheres and particles, applied in the field of enrichment of glycoproteins, can solve the problem of no improvement in the hydrophilicity of materials, achieve good practical value and application prospects, high reaction efficiency, and increase the effect of bonding amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

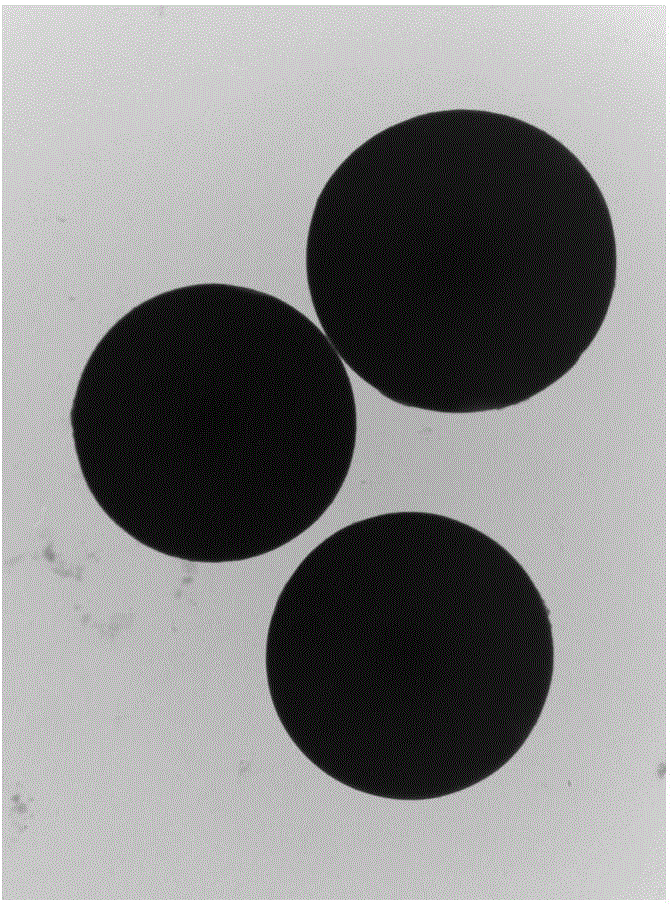

[0020] 1. Preparation of monodisperse core-shell polymer nanoparticles

[0021] In a 150mL round bottom flask, add 80mL of toluene, add 6g of silica gel particles with a particle size of 5μm, and 3g of 3-mercaptopropyltriethoxysilane, and sonicate for 1 minute, so that the added reagents and particles are evenly dispersed in the solution In the process, a condenser was connected to the flask, a magnetic stirrer was added, and the magnetic stirrer was kept at a speed of 300 rad / min. The reaction device was placed in an oil bath, heated to reflux for 6h, then the reaction was stopped and cooled to room temperature. Then use a high-speed centrifuge to centrifuge at a speed of 10,000 rad / min, remove the supernatant, use toluene, acetone, methanol, and acetone to filter and wash in sequence, repeat the suction and filter washing three times, and vacuum dry in a vacuum oven at 50°C for 24 hours. Hours, the modified silica gel particles of the silylating agent were obtained.

[002...

Embodiment 2

[0031] 1. Preparation of monodisperse core-shell polymer nanoparticles

[0032] In a 150mL round bottom flask, add 80mL of toluene, add 5g of silica gel particles with a particle size of 5μm, 3g of 3-mercaptopropyltriethoxysilane, and sonicate for 1 minute, so that the added reagents and particles are evenly dispersed in the solution In the process, a condenser was connected to the flask, a magnetic stirrer was added, and the magnetic stirrer was kept at a speed of 300 rad / min. The reaction device was placed in an oil bath, heated to reflux for 6h, then the reaction was stopped and cooled to room temperature. Then use a high-speed centrifuge to centrifuge at a speed of 10,000 rad / min, remove the supernatant, use toluene, acetone, methanol, and acetone to filter and wash in sequence, repeat the filter and wash 3 times, and vacuum dry in a vacuum oven at 50°C for 24 hours to obtain Silica gel particles modified with silylating agents. In a 100mL round bottom flask, install a c...

Embodiment 3

[0035] 1. Preparation of monodisperse core-shell polymer nanoparticles

[0036] In a 150mL round bottom flask, add 80mL of toluene, add 4g of silica gel particles with a particle size of 5μm, and 3g of 3-mercaptopropyltriethoxysilane, and sonicate for 1 minute, so that the added reagents and particles are evenly dispersed in the solution In the process, a condenser was connected to the flask, a magnetic stirrer was added, and the magnetic stirrer was kept at a speed of 300 rad / min. The reaction device was placed in an oil bath, heated to reflux for 6h, then the reaction was stopped and cooled to room temperature. Then use a high-speed centrifuge to centrifuge at a speed of 10,000 rad / min, remove the supernatant, and use toluene, acetone, methanol, and acetone to filter and wash in sequence, repeat the filter and wash three times, and dry in a vacuum oven at 50°C. After 24 hours, silica gel particles of the modified silylating agent were obtained. In a 100mL round bottom flas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com