Anaerobic adhesive for surface bonding of inert metal

An inert metal and anaerobic adhesive technology, applied in the field of anaerobic adhesives, can solve problems such as affecting work efficiency, polluting the atmosphere, and low strength, and achieve the effects of improving work efficiency, avoiding threats, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Above-mentioned anaerobic glue is prepared according to the following preparation method, comprises the following steps:

[0024] A. Add the acrylate oligomer, acrylate monomer and chelating agent weighed in parts by weight into the reaction flask, and stir at 20-40°C;

[0025] B. Add the accelerator, co-accelerator, polymerization inhibitor, lubricant and thickener weighed in parts by weight to the solution in step A and stir evenly;

[0026] C. Add the initiator weighed in parts by weight to the solution in step B, stir and discharge below 35°C.

[0027] In the present invention, preferably, 0.01-1 part of dye can be added to the anaerobic adhesive. In the present invention, the acrylate oligomer is bisphenol A epoxy acrylate, bisphenol A epoxy methacrylate, propylene glycol adipate polyester acrylate, propylene glycol adipate polyester methacrylate , one or more of urethane acrylate and urethane methacrylate. The acrylate monomer is hydroxyethyl methacrylate, hydr...

Embodiment 1

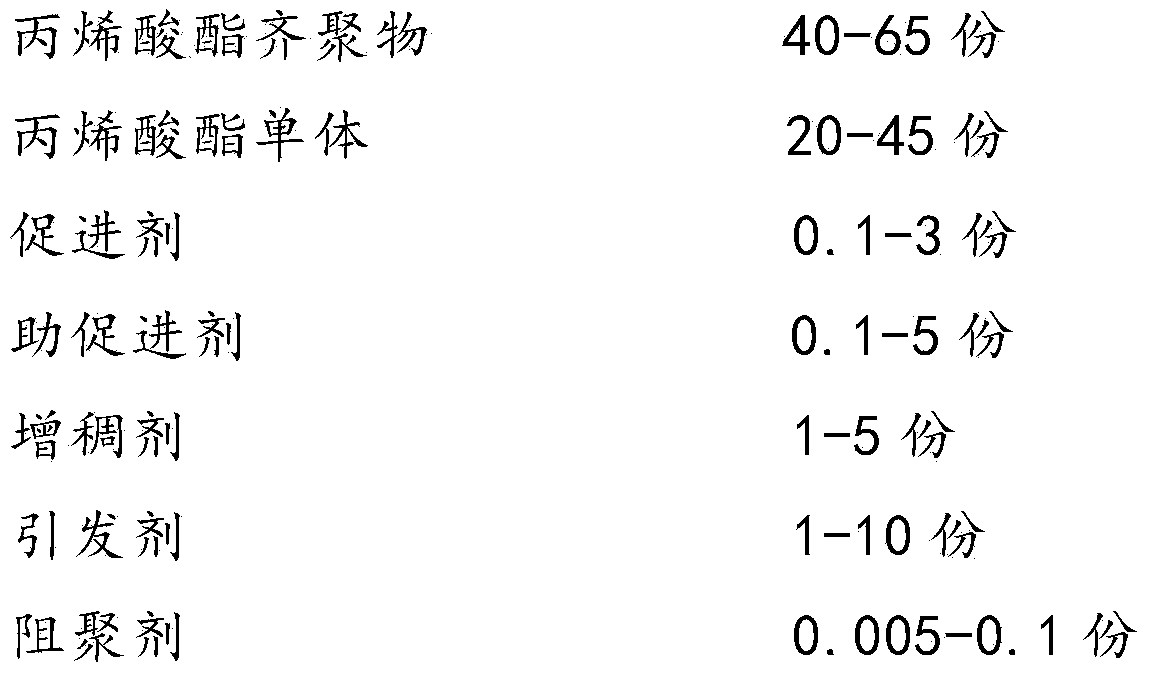

[0029] A kind of anaerobic glue that is used for inert metal surface bonding, the proportioning of parts by weight of described composition is as follows:

[0030]

[0031] The preparation method is to add bisphenol A epoxy acrylate, isobornyl acrylate and disodium ethylenediaminetetraacetic acid into a reaction bottle according to the parts by weight of the above components, and stir at 20° C. for 1.5 hours; then Add acetophenhydrazine, o-sulfanilimide, N,N-dimethyl-p-toluidine, polytetrafluoroethylene wax, glycerin, fast red, p-benzoquinone and fumed silica, stir at high speed until completely dissolved ; Add cumene hydroperoxide at a temperature of 34°C and stir for 1.5 hours. The output is placed in a low-density polyethylene bottle.

Embodiment 2

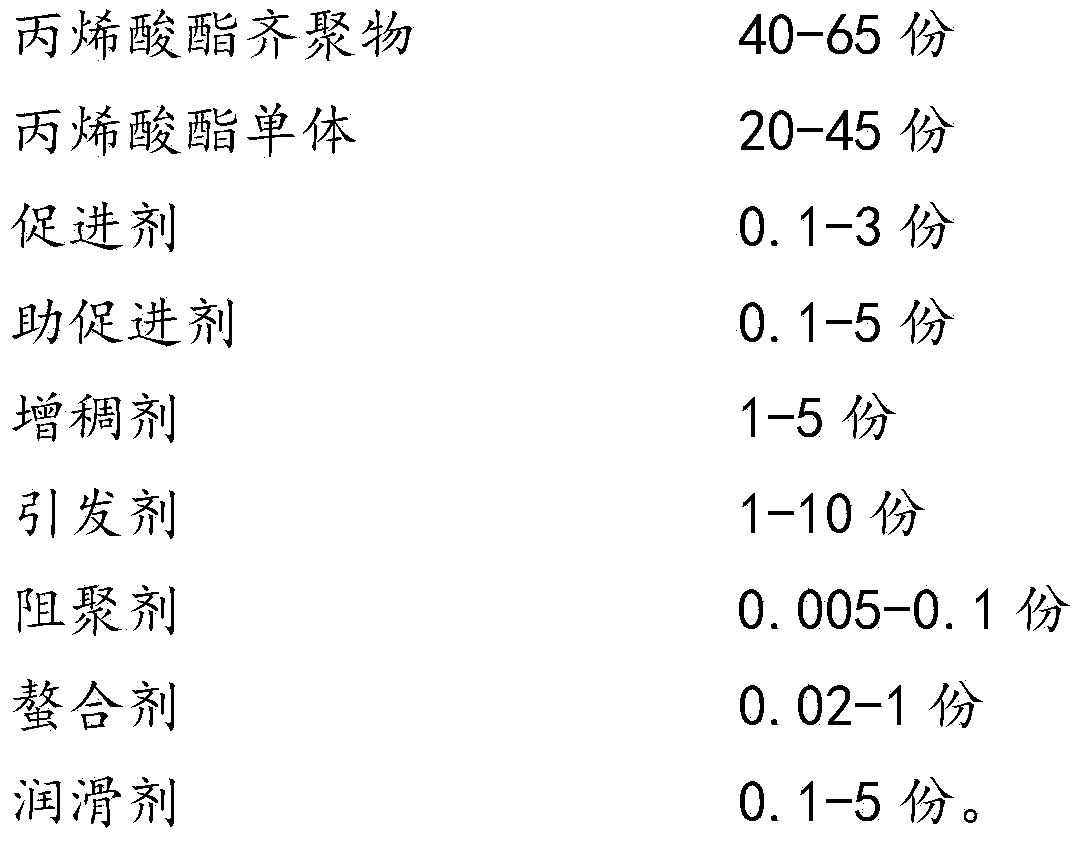

[0033] A kind of anaerobic glue that is used for inert metal surface bonding, the proportioning of parts by weight of described composition is as follows:

[0034]

[0035]

[0036] The preparation method is to add propylene glycol adipate polyester acrylate, hydroxypropyl methacrylate and tetrasodium ethylenediaminetetraacetic acid into a reaction bottle according to the parts by weight of the above components, and stir at 40°C for 1.5 Add benzoyl hydrazide, o-sulfanyl benzimide, N,N-dimethyl-p-toluidine, polyethylene wax, glycerin, fast red, p-benzoquinone and fumed silica, and stir at high speed until Dissolve completely; then add benzoyl peroxide at 30°C, stir for 1.5 hours, discharge, and place in a low-density polyethylene bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com