Photocatalyst for visible light transformation and preparation method of same

A photocatalyst and visible light technology, applied in the fields of environment and energy, can solve the problem that the visible light catalytic efficiency needs to be further improved, and achieve the effects of high visible light catalytic activity, stable structure and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

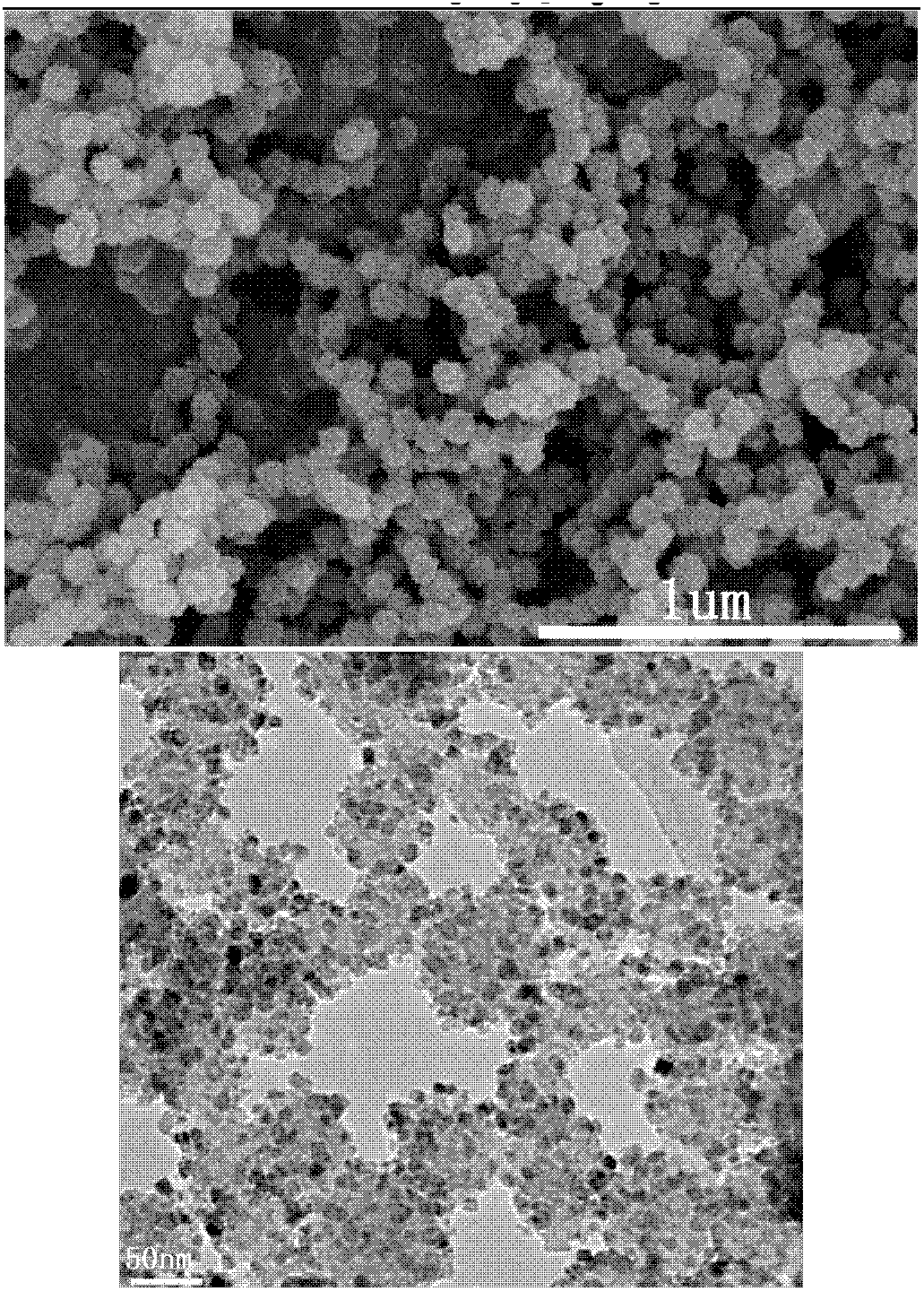

[0024] Dissolve 0.6g of phenol and 1mL of 37% formaldehyde solution into 15mL of 0.1M NaOH aqueous solution and keep warm at 70°C for 0.5h. At the same time, add 15mL of aqueous solution containing 0.91g of surfactant F127 (commercially available) and mix well. After mixing, the solution Keep the temperature at 66° C. for 2 hours, then add 50 mL of water to the solution and keep it for 16 hours. Finally, 15mL of the solution was mixed with 56mL of water, and kept in a 130°C reactor for 24h. The final product was centrifuged and washed with ethanol for 3 times to obtain phenolic resin (NS-PR), whose powder particle size was about 80nm.

[0025] Add NS-PR to 70mL ethanol solution, then add 0.4mL isopropyl titanate to the system, keep it warm at 180°C for 15h, filter and wash the product through ethanol, and dry at 105°C to obtain a yellow powder In order to further improve the catalytic activity, after drying in N 2 In the atmosphere, the air flow rate is 60ml / min, heated at...

Embodiment 2

[0028] Take 1g of phenol, dissolve 1mL of 37% formaldehyde solution into 15mL of 0.1M NaOH aqueous solution, incubate at 70°C for 0.5h, incubate at 130°C for 24h, centrifuge the final product, wash with ethanol repeatedly for 3 times, and obtain the phenolic resin ( NS-PR), the powder particle size is about 200nm.

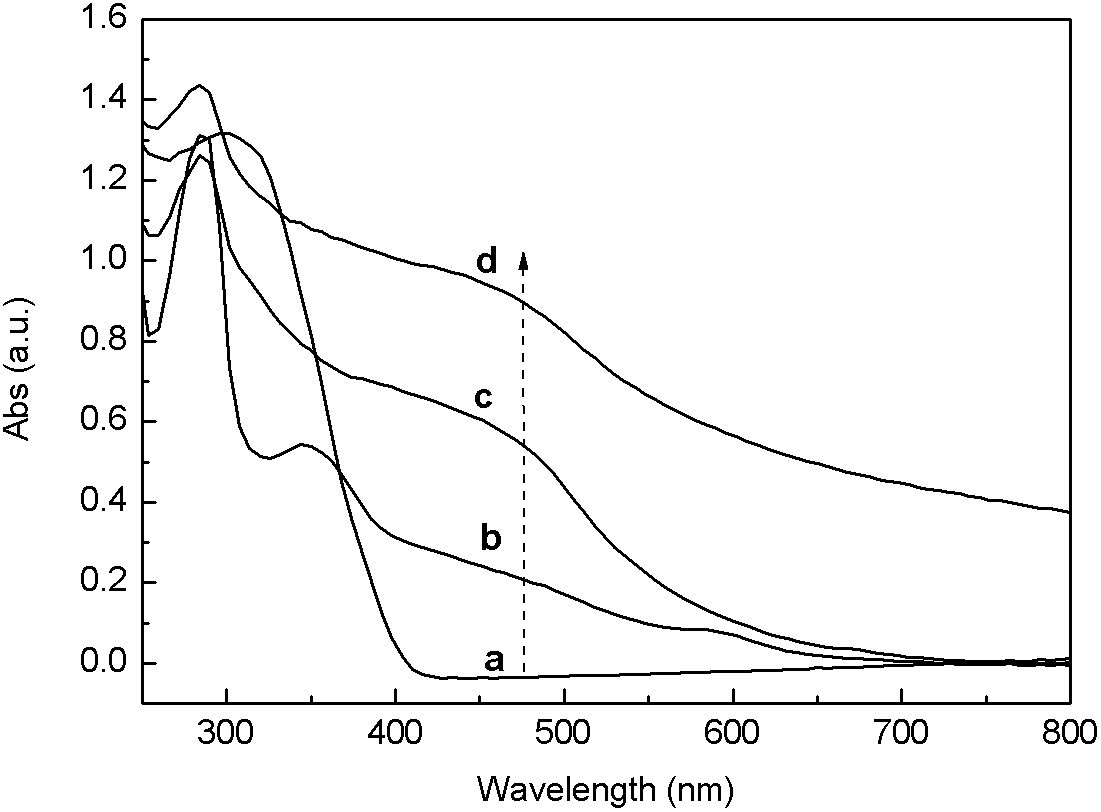

[0029]Add NS-PR to 70mL ethanol solution, then add 0.4mL isopropyl titanate to the system, keep it warm at 180°C for 15h, filter and wash the product through ethanol, and dry at 105°C to obtain a yellow powder In order to further improve the catalytic activity, after drying in N 2 In the atmosphere, the air flow rate is 60ml / min, heated at 300°C for 3h to obtain Catalyst, the catalyst can degrade methyl orange at a rate of 10 mg / g under visible light conditions.

Embodiment 3

[0031] Dissolve 0.6g of phenol and 1mL of 37% formaldehyde solution into 15mL of 0.1M NaOH aqueous solution and keep it warm at 70°C for 0.5h. At the same time, add 15mL of aqueous solution containing 0.91g of surfactant F127 and mix well. After mixing, the solution is kept at 66°C 2h, then 50mL of water was added to the solution and incubated for 16h. Finally, 15mL of the solution was mixed with 56mL of water, and kept in a 130°C reactor for 24h. The final product was centrifuged and washed with ethanol for 3 times to obtain phenolic resin (NS-PR), whose powder particle size was about 80nm.

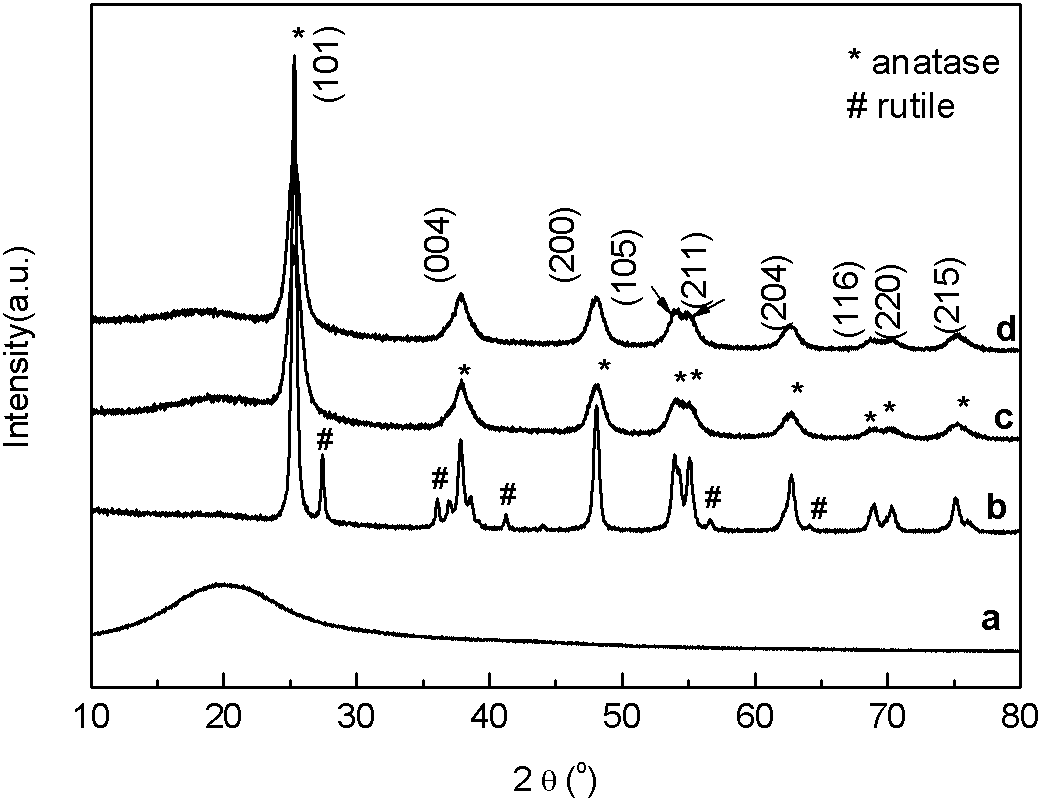

[0032] Add NS-PR to 70mL ethanol solution, then add 1.5mL isopropyl titanate to the system, keep it warm at 180°C for 15h, filter and wash the product through ethanol, and dry at 105°C to obtain a yellow powder In order to further improve the catalytic activity, after drying in N 2 In the atmosphere, the air flow rate is 60ml / min, heated at 300°C for 3h to obtain Catalyst (see fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com