Fiber reinforced composite material rib concrete drainage pipe pile

A composite material, fiber-reinforced technology, applied in sheet pile walls, soil protection, construction, etc., can solve the problems of insensitive thickness and low cost, and achieve extended life, corrosion resistance cavity hollow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

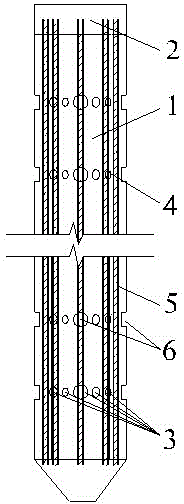

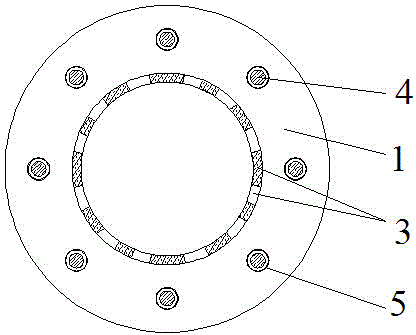

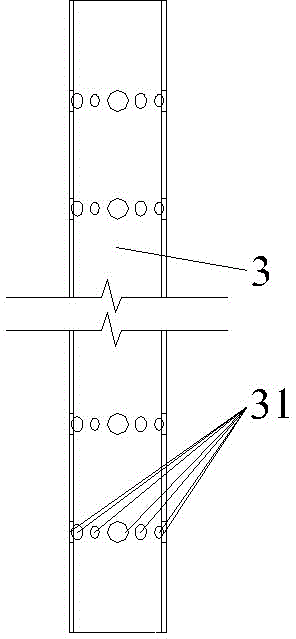

[0025] The fiber-reinforced composite material-reinforced concrete drainage pipe pile of the present invention comprises: a concrete drainage pipe pile body 1, a head plate 2, an inner sleeve 3, a fiber-reinforced composite material reinforcement 4, a steel pipe 5, and drainage holes 6. Detailed description: make prefabricated reinforced concrete pipe piles with a diameter of 450mm, wall thickness of 90mm, pile length of 10m, opening rate of about 5%, pre-tensioned prestressed centrifugal molding process, steam curing (the specific size can be adjusted according to the requirements of the design institute) .

[0026] Fiber-reinforced composite material reinforcement material is carbon fiber, unsaturated polyester, epoxy resin or phenolic resin as the matrix. Composite material tendons are bound with durable fibers, bonded with durable colloid materials, and connected with durable bolts;

[0027] Open holes in the pile body with a diameter of 8cm, 4 holes are distributed along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com