Novel surface-mounted inductor

A chip inductor, a new type of technology, is applied in the direction of transformer/inductor shell, transformer/inductor core, transformer/inductor parts, etc. Easy to loosen with the base and other problems, to achieve the effect of increasing strength, preventing loosening and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

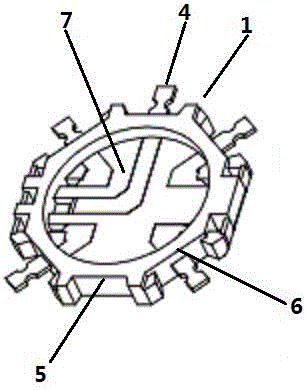

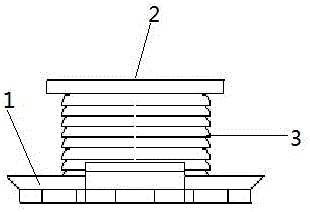

[0015] Such as figure 1 , 2 As shown, the chip inductor includes a base 1, an I-shaped magnetic core 2 located on the base 1, and a coil winding 3 on the magnetic core 2. One end of the magnetic core 2 is pasted on the base 1 with PIN pins. The base The PIN pin of 1 is welded to the end of the coil winding, and a gap 5 is added to the black injection molding of the non-PIN pin end of the base 1, and the thickness of the black wrapping plastic layer of the PIN pin at the PIN pin is increased 6, and the bonding surface of the base 1 and the magnetic core 2 is added. Punch the EDM pattern 7, and weld the five PIN pins 4 of the base to the ends of the coil winding 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com