Composite anchor rod device and method for fastening cross section by using anchor rod device in anchoring manner

A composite and anchor technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of insufficient concrete, reduce the bonding strength of new and old interfaces, and cumbersome construction procedures, so as to achieve high utilization rate and avoid interface Stripping, making simple and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] As shown in the drawings, the composite bolt device of the present invention includes a bolt 1, a positioning nut 2, a fixing cone 3, a fixing sleeve 4, a pressure plate 5 and a fastening nut 6;

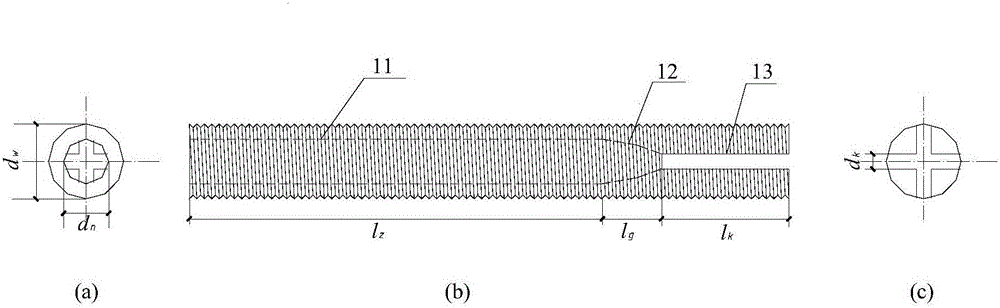

[0054] Anchor rod 1 is a threaded pipe with outer diameter d w The insertion end of the anchor rod 1 is provided with a separation groove communicating with the threaded hole. The anchor rod 1 is axially divided into a hollow section 11, a transition section 12 and a slotted section 13 with separation grooves. The length l of the hollow section 11 z 30mm, aperture d n is 6mm. The length l of the transition section 12 g is 4 mm, and the inner diameter of the transition section 12 gradually converges in the axial direction. The slotted section 13 has a separation groove, which is an axially extending cross groove, and is used to divide the rod body of the anchor rod 1 into several deformed parts that are extruded and expanded outward. The length of the cross groove is l k 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com