UHPC board and concrete combined type frame slab bridge and construction method thereof

A combined frame and concrete technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of long construction period, accelerated corrosion of internal steel bars, and high construction costs, so as to enhance crack resistance and mechanical properties and save energy. Construction cost, convenient and fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

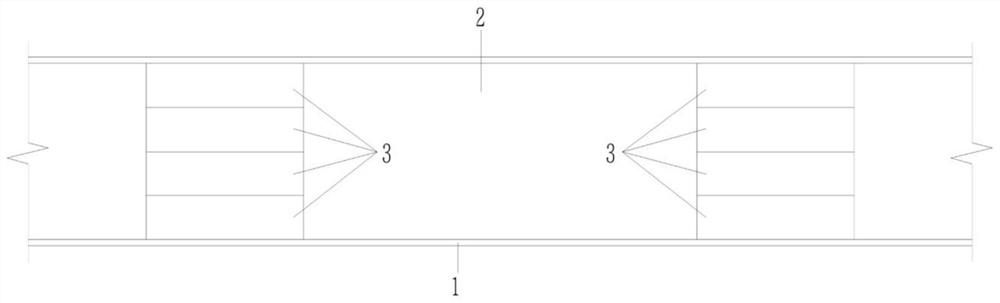

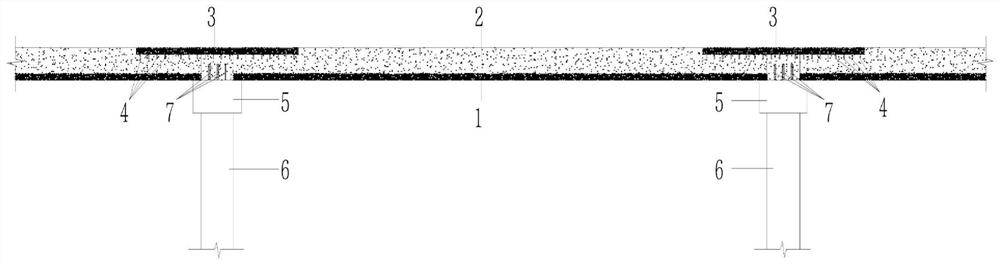

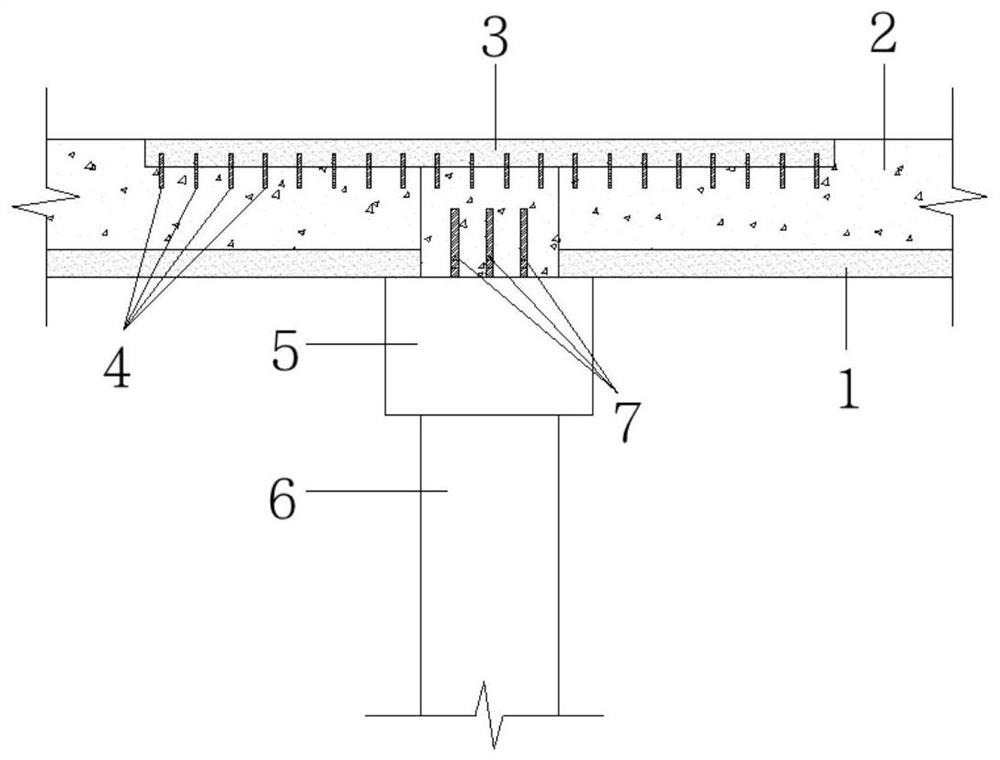

[0040] Such as figure 1 , 2 , 3, and 4, the UHPC plate and concrete frame slab bridge proposed by the present invention consists of a prefabricated channel UHPC plate 1, a steel truss stiffener 8, an angle steel connector 11, a UHPC prefabricated plate 3 in a negative moment zone, and a main The beam is composed of cast-in-place ordinary concrete 2, bridge piers 6 and cover beams 5; among them, the bridge piers 6 and cover beams 5 are ordinary concrete components, and the construction is completed on site, and the cover beams 5 are reserved at the top of the cover beams. It is used to strengthen the connection between the cast-in-place ordinary concrete 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com