Bending member for bamboo reinforced wood beam and manufacture method thereof

A technology for bending components and wooden beams, applied in building construction, building maintenance, construction, etc., can solve the problems of large influence on component appearance, inability to reinforce component rigidity, and high cost of fiber cloth, so as to suppress unfavorable damage modes, Guaranteed reinforcement effect and low labor demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technology, features, purposes and effects of the present invention, specific implementations of the present invention will now be described with reference to the accompanying drawings.

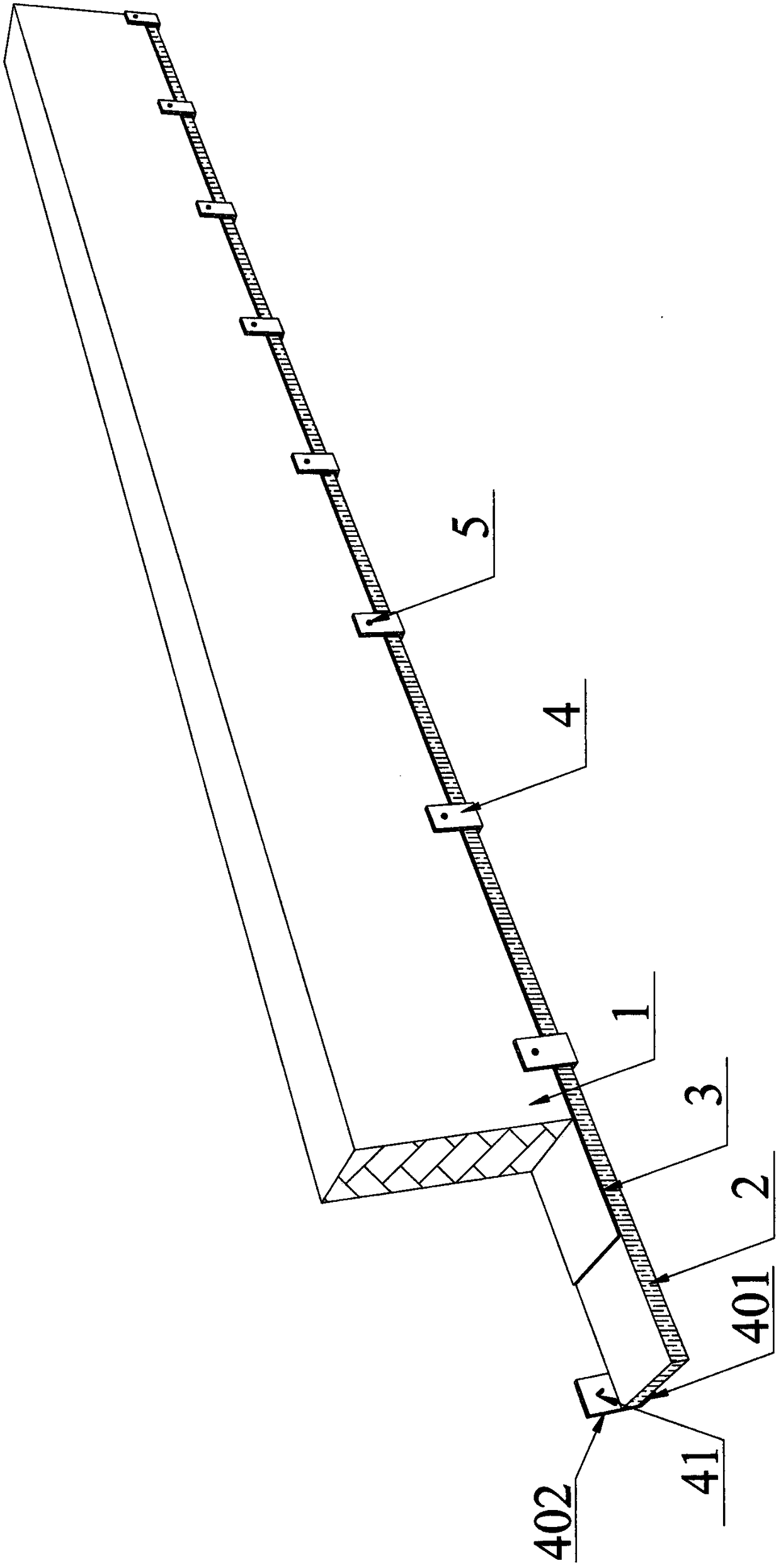

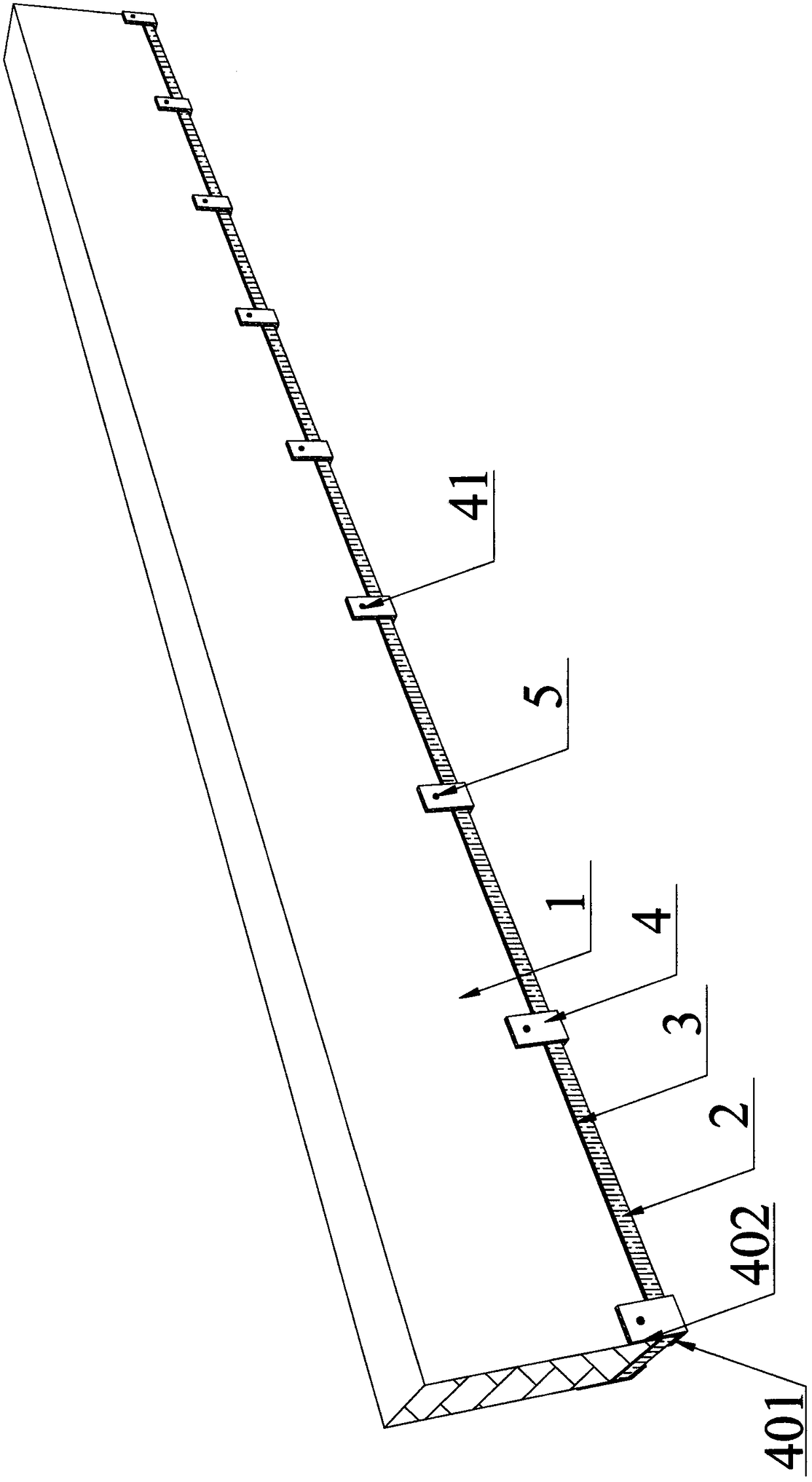

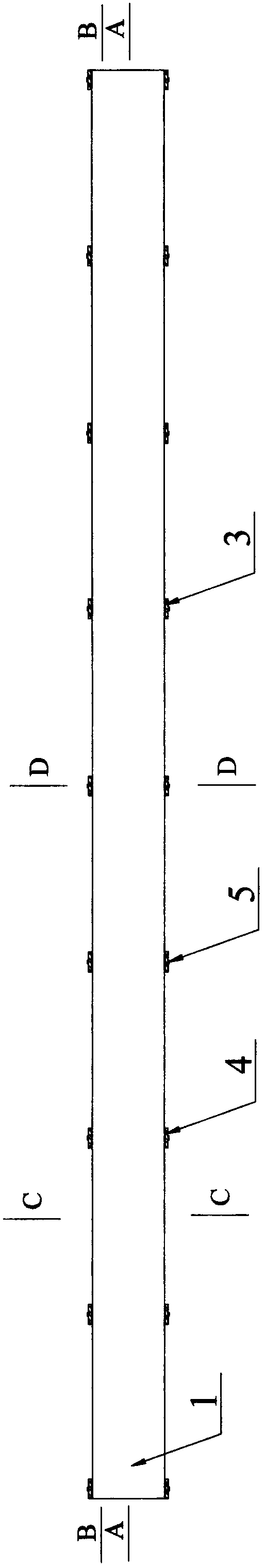

[0038] As shown in the accompanying drawings, the present invention provides a bamboo reinforced wooden beam bending member, comprising a wooden beam 1, a bamboo board 2, an adhesive 3, an angular fastener 4, and an anchor bolt 5. It is characterized in that the bamboo board 2 is located on the wooden beam 1 bottom, the planar size of the bamboo board 2 is less than or equal to the size of the bottom surface of the wooden beam 1, the bamboo board 2 is tightly bonded to the bottom surface of the wooden beam 1 with an adhesive 3, and the angle fastener 4 is composed of a bottom flange 401 and a side flange 402 perpendicular to each other, The angular fasteners 4 are arranged at discrete intervals along the longitudinal direction of the woode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com