Leeward type wind turbine

A technology of wind turbines and wind wheels, applied in the direction of wind engines, wind engines consistent with the wind direction, wind engine control, etc., to achieve the effect of reducing the cost of blades and the whole machine, and improving the yaw control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

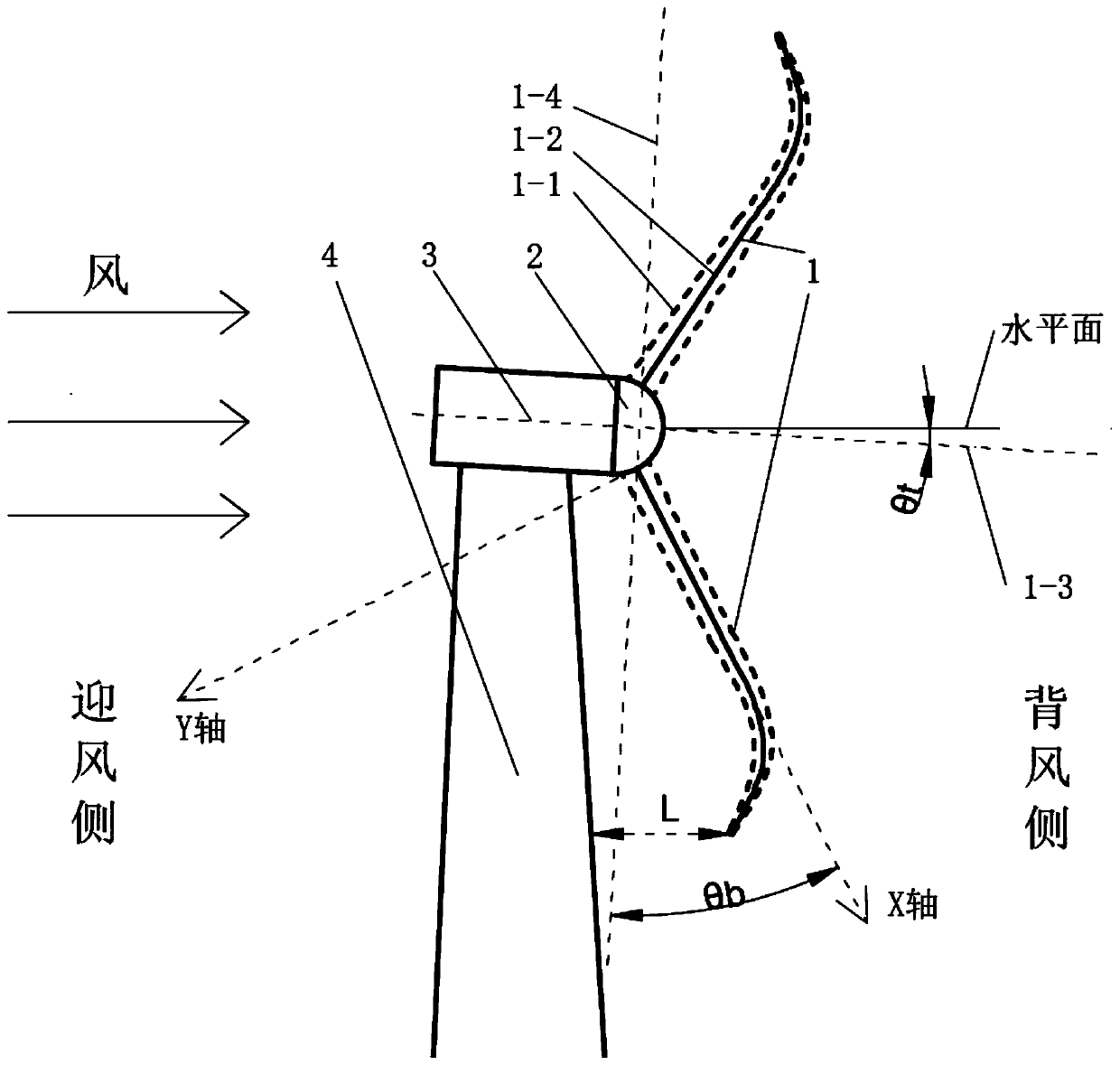

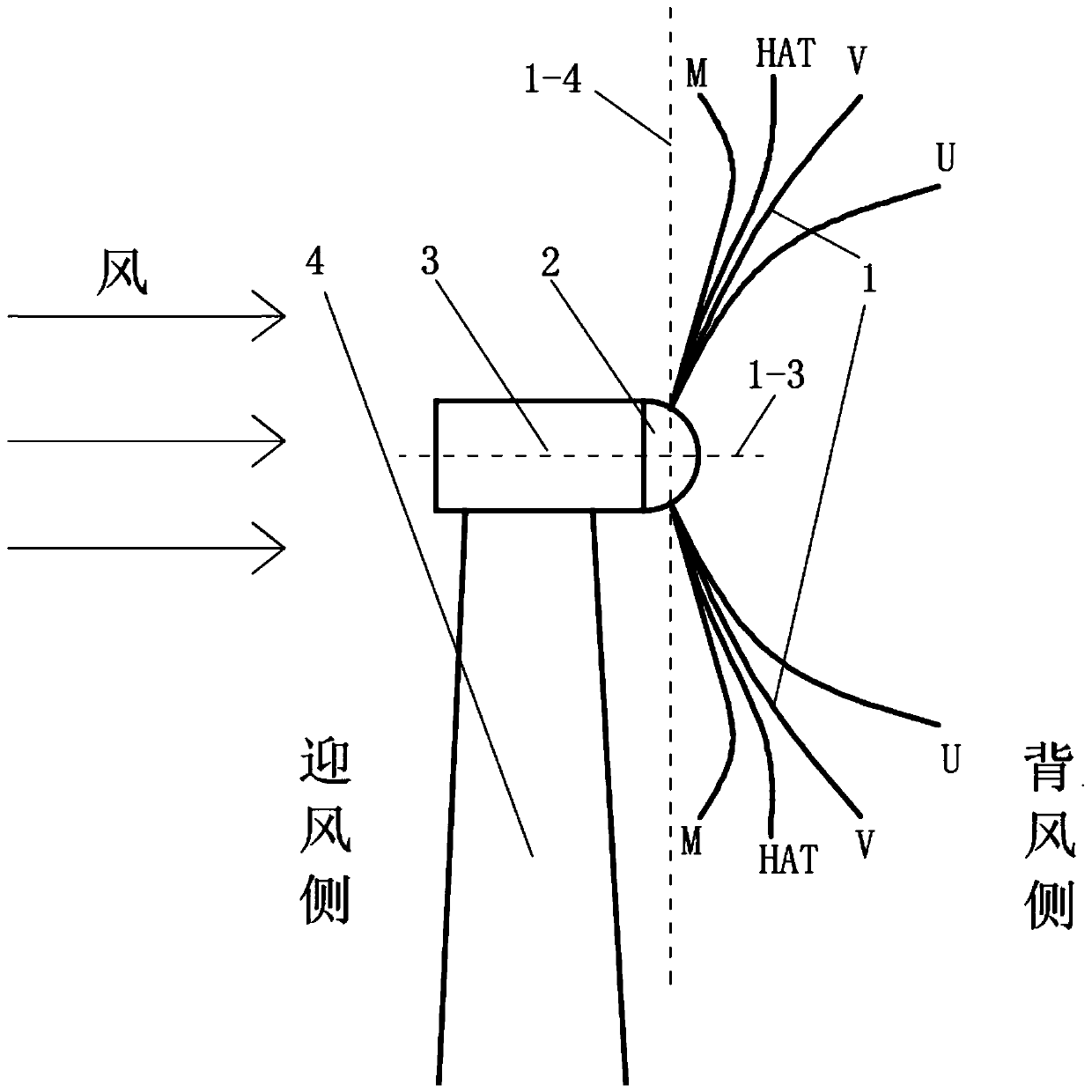

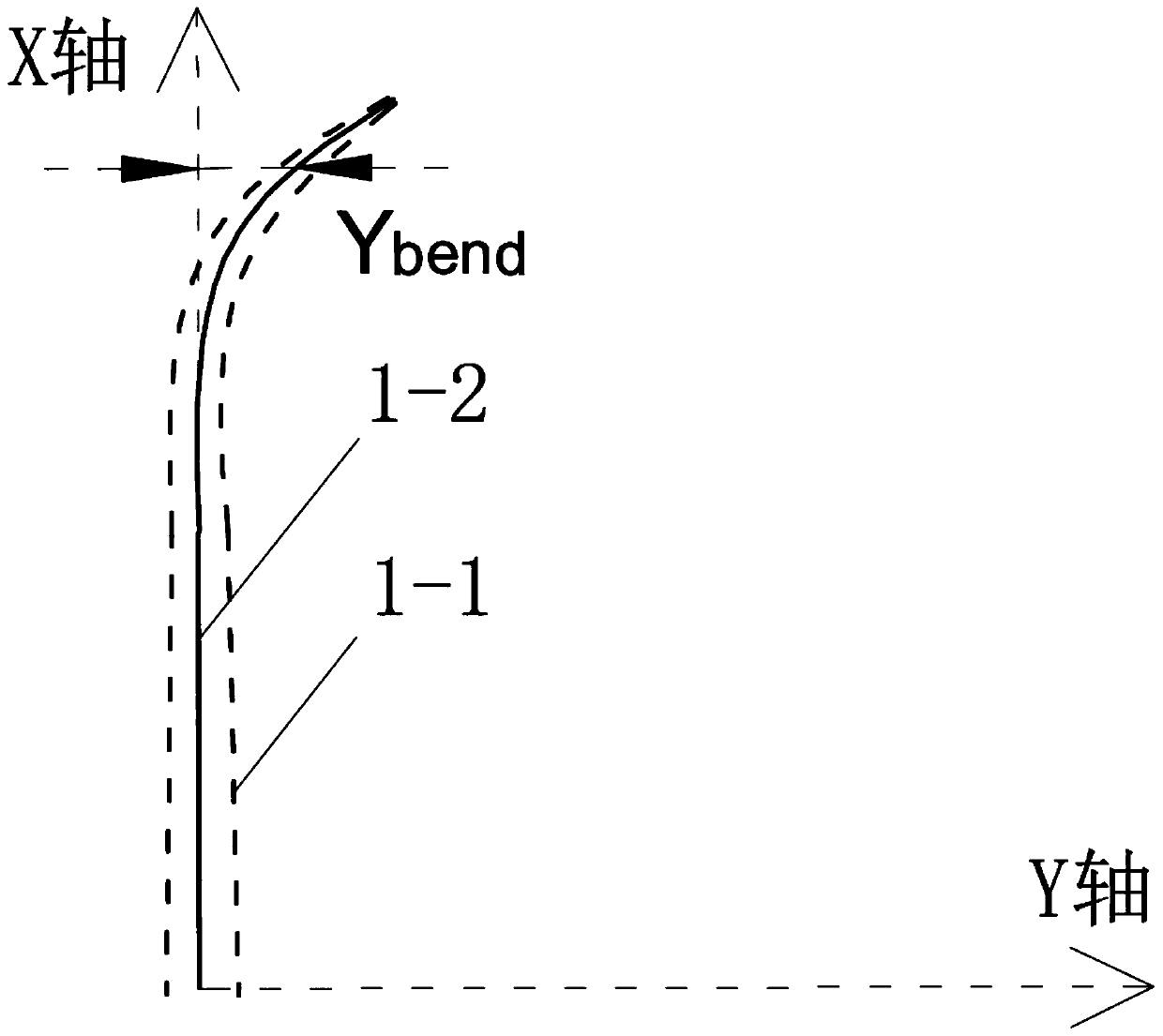

[0025] A leeward wind turbine, comprising a wind wheel 1 and a wind wheel rotation mechanism, the wind wheel 1 includes several blades 1-1, the inner ends of the several blades 1-1 are fixedly connected to the upper end of the wind wheel rotation mechanism, and the several blades 1-1 1 are circularly distributed around the wind rotor rotating mechanism, and the vertical cross section of the wind rotor 1 presents an M shape when the wind is still. In the prior art, there is a V-shaped cone-angle wind rotor, but the biggest feature of the wind rotor 1 of the present invention is that it is M-shaped when stationary, and the wind rotor 1 will gradually deform as the wind speed increases.

[0026] Further, the wind wheel rotation mechanism includes a hub 2, a nacelle 3 and a tower 4, the inner ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com